Radiant Barrier Reflective Foil Insulation Guide

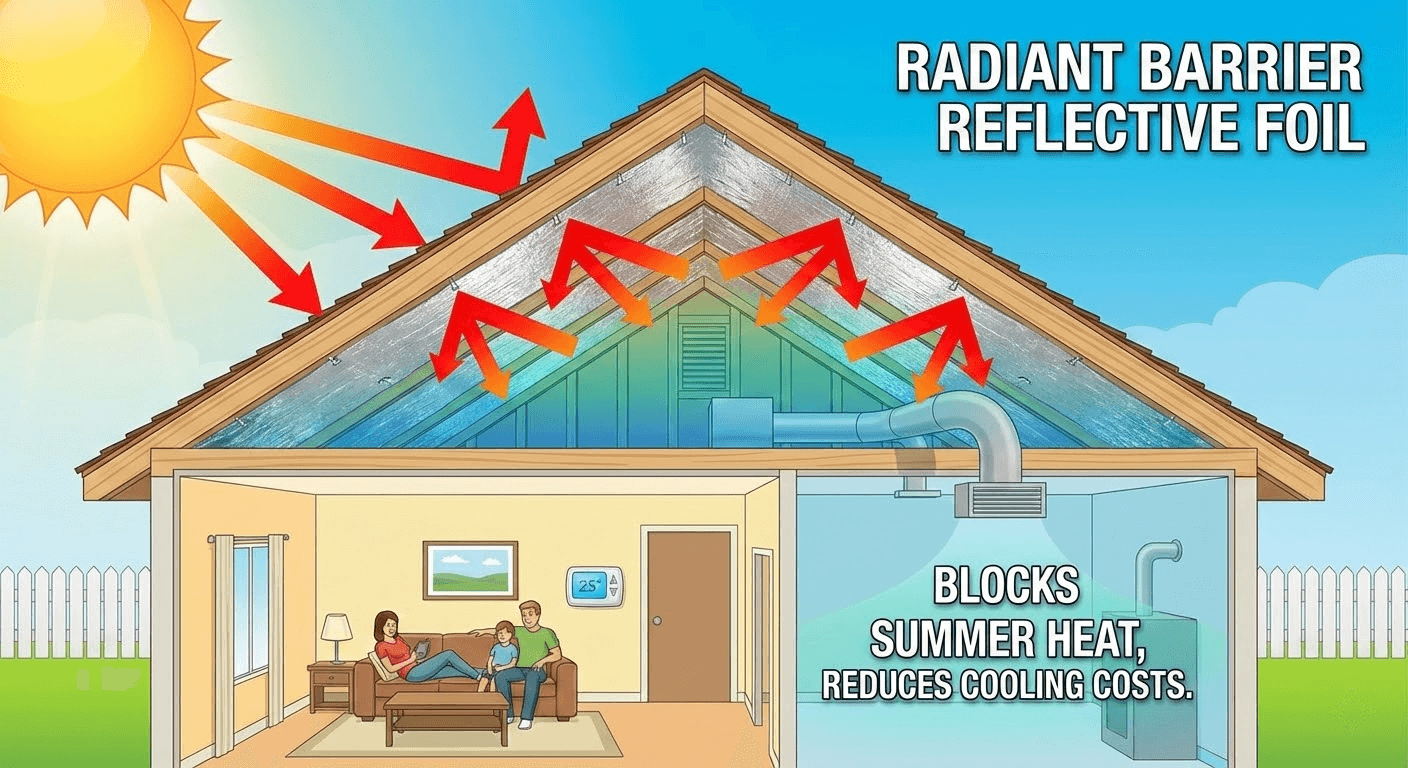

Hot upstairs rooms on sunny afternoons often trace back to radiant heat coming off a roof deck. Radiant barrier reflective foil insulation reduces that radiant transfer in attic and roof assemblies, so less heat radiates onto ducts, framing, and ceiling surfaces. DOE describes radiant barriers as a highly reflective material installed primarily in attics to reduce summer heat gain and cooling costs.

This guide covers what these products do, where they work, how to install them, and how to choose specs for bulk purchasing.

What Radiant Barrier Reflective Foil Insulation Is

How radiant barriers work

Heat moves by conduction, convection, and radiation. A radiant barrier targets radiation by using a low-emittance reflective surface, usually aluminum foil, to reflect infrared energy and emit less radiant heat toward the cooler side.

DOE’s core requirement is short and strict: “To be effective, the reflective surface must face an air space.”

What to check on a spec sheet

Two numbers and one document question do most of the work:

-

Emittance: ASTM C1313 limits the scope to sheet materials with at least one surface having far-infrared emittance of 0.1 or less.

-

Moisture and fire behavior: C1313 references evaluations such as water vapor transmission and surface burning characteristics, plus corrosivity and tear resistance. Install requirements: DOE emphasizes the air-space dependency for radiant barriers and reflective insulation systems.

Where It Works Best and Where It Does Not

Best-fit applications

Radiant barrier reflective foil insulation is most useful where the roof gets very hot and the assembly includes an air space. DOE says radiant barriers are “more effective in hot climates than in cool climates,” especially when cooling ducts are located in the attic.

Best matches:

-

Vented attics in warm, sunny regions

-

Homes with cooling ducts in the attic

-

Metal buildings and agricultural structures

A common field pattern: the attic air is hot, yet the bigger clue is how quickly duct surfaces and the ceiling plane warm up during peak sun. In an anonymized retrofit on a single-story home with attic ducts, crews stapled foil to rafters with a consistent air gap and verified ventilation stayed open. The homeowner reported faster afternoon cooldown and less “heat radiating” from the ceiling during the hottest hours.

When performance drops

Three common reasons:

-

No air gap, foil tight to another surface

-

Dust accumulation. DOE warns dust reduces reflective capability and recommends installing to minimize dust buildup.

-

Wrong expectation in cold climates. DOE notes it is usually more cost-effective to add more thermal insulation than to add a radiant barrier in cool climates.

Practical Benefits You Can Expect

Comfort and HVAC impact

Expect the biggest impact during peak sun hours, because less radiant energy reaches attic surfaces that influence comfort and HVAC load.

DOE reports that some studies show radiant barriers can reduce cooling costs by 5% to 10% in a warm, sunny climate.

In controlled testing, ORNL compared attic configurations and found summer daytime heat flow through the attic floor was 33%, 50%, and 19% lower than a control attic, depending on whether the system used perforated low-e foil laminated OSB decking, low-e foil stapled on rafters, or a liquid-applied low-emittance coating.

Moisture and durability considerations

Foil can change drying behavior, so placement matters. DOE strongly recommends you do not apply foil radiant barriers directly on top of attic floor insulation, because the foil can trap moisture in fibrous insulation and collect dust.

If you are installing in barns, shops, or high-traffic attics, prioritize reinforcement and handling strength, and verify referenced evaluations like tear resistance and corrosivity.

How to Install It Correctly

Core rules

-

Preserve the air space

-

Face the reflective side toward that air space

-

Keep attic ventilation paths open

-

Avoid installs that expose the reflective face to heavy dust when you have alternatives

DOE recommends allowing foil to “droop” between attachment points to create at least a 1 inch air space between the foil and the roof deck.

Common install setups

Attic retrofit:

-

Staple foil across the bottom of rafters or truss chords

-

Maintain droop and keep soffit and ridge airflow clear

New build:

-

Foil-faced roof decking can keep the low-emittance surface cleaner over time

Safety note: DOE warns reflective foil conducts electricity, so avoid contact with bare wiring and follow manufacturer safety precautions.

How to Choose the Right Product for Bulk Buying

A simple spec checklist

-

Emittance consistent with C1313 scope, 0.1 or less on at least one surface

-

Reinforcement for tear resistance during handling

-

Perforated versus non-perforated based on moisture strategy

-

Roll width and length that reduce seams and labor

Matching product type to the job

ORNL’s controlled comparison suggests rafter-stapled low-emittance foil can provide strong summer daytime reduction in attic-floor heat flow when installed with a proper air space.

Foil-laminated decking is convenient for new construction, and coatings can help when sheet installs are impractical, with results tied to application quality.

Procurement Notes for Contractors and DIY Buyers

A quick quantity method:

-

Measure coverage area

-

Add 8% to 12% for overlaps and cutoffs

-

Add seam tape and fasteners as separate line items

If you routinely source agricultural, gardening, landscaping, and light building supplies alongside insulation accessories, consolidating orders can simplify scheduling. Wellco Wholesale positions itself as a factory-direct wholesaler across these categories for bulk buyers.

Conclusion

Radiant barrier reflective foil insulation works best when installed with an air space, kept reasonably clean, and used where summer radiant gain is a real driver. DOE highlights those installation dependencies and cites 5% to 10% cooling cost reductions in warm, sunny climates in some studies.

Next step: confirm your assembly, pick a product type that matches it, and do a quick on-site check for air gap, ventilation continuity, and safe clearance around wiring before you call the job done.

Frequently Asked Questions

Does radiant barrier reflective foil insulation replace fiberglass or spray foam?

It complements bulk insulation. DOE explains radiant barriers reduce radiant heat gain, while common insulation materials mainly slow conductive heat flow.

Should the foil touch the roof deck?

It performs best facing an air space, and DOE recommends maintaining about a 1 inch air space by allowing foil to droop between attachment points.

What moisture mistake should I avoid?

DOE strongly recommends avoiding foil directly on top of attic floor insulation, since it can trap moisture in fibrous insulation and collect dust.

What is the biggest safety risk?

DOE warns reflective foil can conduct electricity, so avoid contact with bare wiring and follow manufacturer safety precautions.