Is Double Reflective Foil Insulation Worth It? Pros & Cons

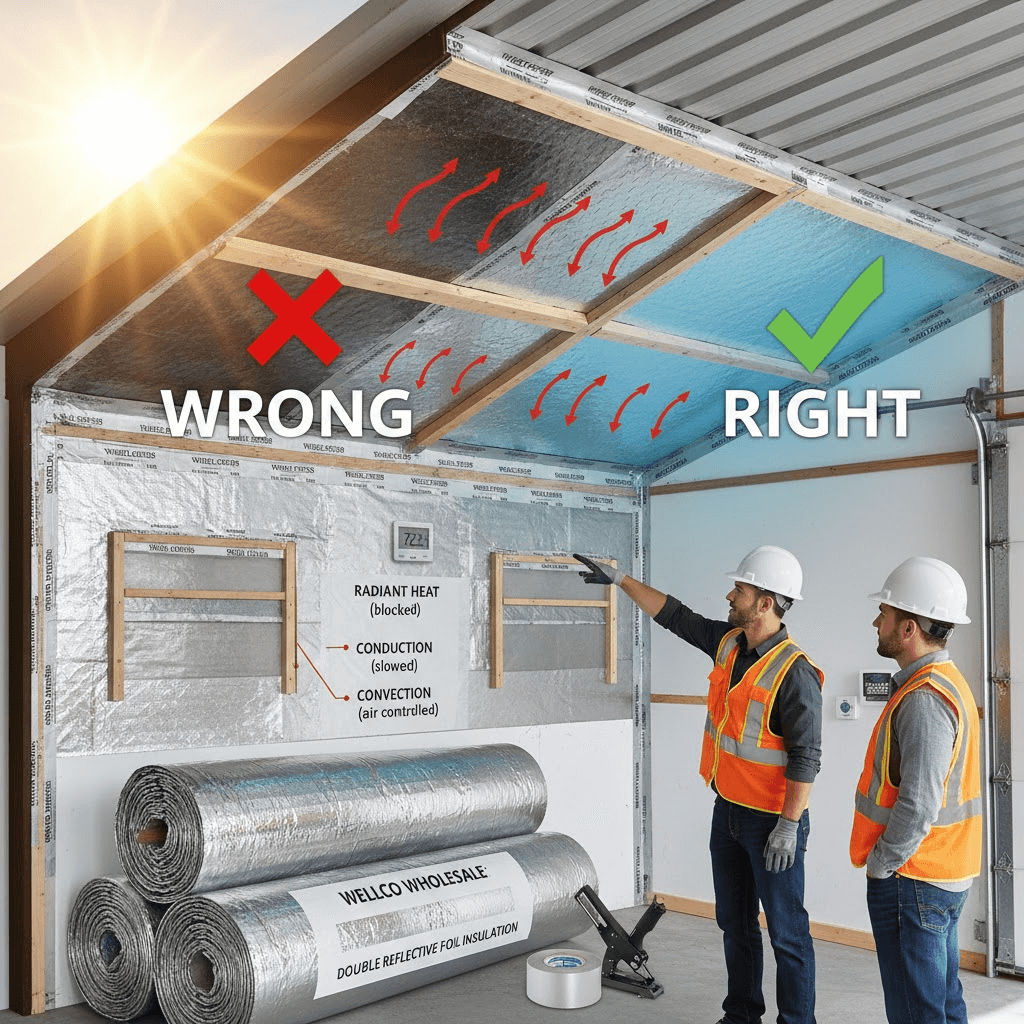

If you’ve ever stepped into a metal garage on a sunny afternoon and felt the heat “radiating” down from the roof like a broiler, you already know why reflective systems get so much attention. The problem is, a lot of people buy reflective rolls expecting “instant high R-value,” staple them up with no air gap, skip proper seam sealing, and then get disappointed.

Double reflective foil insulation can be worth it—but only when you use it for what it’s designed to do: reduce radiant heat transfer as part of a complete assembly. Done right, it can improve comfort fast in garages, shops, agricultural buildings, and warehouses. Done wrong, it can become an expensive shiny liner.

For bulk and trade buyers, repeatable results come from consistent specs, reliable roll sizing, and install-ready accessories (tape, fasteners, edge sealing). Wellco Wholesale supports professional customers buying in volume (while also serving retail buyers), which helps when you need dependable product specs and steady supply for ongoing projects.

Double Reflective Foil Insulation: What It Is and How It Works

Layers & materials (what “double” means)

“Double” usually means two reflective faces—one on each side of the roll—paired with a thin core (often double-bubble or foam). Many jobsite-friendly products add scrim/mesh reinforcement to reduce tearing during fast installs.

Here’s the key performance principle (and it’s the one most installs get wrong):

-

A reflective face performs best when it faces an adjacent air space.

-

If you sandwich it tight between solid materials, you largely remove the radiant-barrier benefit.

A practical field rule crews use: if at least one foil face “sees” a sealed air gap, performance improves noticeably compared with a fully compressed install.

Radiant vs conduction vs convection (why air gaps matter)

Heat moves in three main ways:

-

Radiation: heat transfer by infrared energy (hot roof “shines” heat toward cooler interior surfaces)

-

Conduction: heat moves through materials by contact

-

Convection: heat rides moving air currents

Double reflective foil insulation targets radiation. That’s why it’s common under metal roofing or in sun-baked structures. But without an air space, you’re mostly relying on the thin core for conduction resistance—which is not why most buyers choose it.

Trade-insight quote (installer mindset): “Reflective insulation doesn’t ‘work’ because it’s shiny—it works because the shiny surface faces an air space that would otherwise absorb radiant heat.”

Typical performance expectations (realistic outcomes)

Expect comfort and peak-heat improvements more than “magic winter savings.” In anonymized field observations on hot, sun-exposed metal buildings, properly installed reflective assemblies commonly show a noticeable reduction in ceiling-zone heat intensity, and many crews report the workspace feels roughly 5–15°F less harsh near the roofline during peak sun hours (range varies by building type, ventilation, and assembly details).

When comparing products, don’t rely on marketing names. Compare these directly:

-

Facing type (true foil vs metallized film)

-

Core type/thickness (double-bubble vs foam)

-

Reinforcement (scrim/mesh)

-

Roll width/length (controls seams and labor)

-

Tape compatibility (adhesion under temperature swings)

Is Double Reflective Foil Insulation Worth It? Pros & Cons

Pros (where it’s a strong choice)

1) Strong radiant heat control (when installed correctly).

On buildings where the roof deck becomes the dominant radiant source, reflective faces can reduce radiant transfer into the occupied space.

2) Lightweight, fast coverage on big surfaces.

On warehouses, agricultural buildings, and shops, labor speed is a major cost driver. A roll-based solution can cover large areas quickly with minimal mess compared with fiber insulation.

3) Can improve air tightness when seams are sealed.

With continuous overlap and proper foil tape, assemblies often reduce drafts and help stabilize interior conditions. In many builds it may also behave like a vapor retarder—but only if seams and edges are fully sealed.

Quick measurable reality check: On large metal-building retrofits, crews often find that sealing seams and edges can reduce “wind washing” significantly—sometimes improving comfort as much as the reflective layer itself.

Cons (where buyers get disappointed)

1) Not a universal replacement for mass insulation.

If your build needs high R-values for cold climates or code-driven requirements, you may still need fiberglass batts, blown insulation, or foam systems. Reflective insulation is best as an assembly component, not the entire thermal strategy.

2) No air space = weak results.

This is the most common failure mode. If it’s installed flat against a surface or compressed between layers, the radiant barrier can’t do much.

3) Moisture/condensation risk if assembly details are wrong.

Metal buildings can “sweat.” Trapping moisture without a ventilation plan can cause dripping, corrosion, or mold issues. The product isn’t the problem—the assembly design is.

Who it’s best for (quick decision checklist)

Double reflective foil insulation is usually worth it when:

-

Your pain point is radiant heat gain (hot roofs, strong sun exposure)

-

You can maintain at least one adjacent air gap

-

You need fast installation and clean handling

-

You’re covering large areas where labor efficiency matters

-

You want seam sealing to also support better air control

It’s less likely to be worth it as a standalone solution when:

-

You need high R-values for winter heating and code compliance

-

You can’t create an air gap

-

Moisture control/ventilation is uncertain or high risk

Key Factors to Check Before You Buy (Bulk + Trade Focus)

Spec sheet must-haves (don’t skip these)

For bulk purchasing, spec discipline prevents rework and returns. Confirm:

-

Facing type: foil vs metallized film

-

Core type/thickness: double-bubble, foam, overall thickness

-

Reinforcement: scrim/mesh (tear resistance)

-

Roll width/length: affects seam count and labor time

-

Temperature range: especially under roofing

-

UV exposure limits: some facings degrade if left exposed

-

Fire documentation: request the product’s available fire/smoke documentation relevant to your application

Installation method compatibility (match your real workflow)

Before you buy pallets, match the product to how crews will install:

-

Stapled to rafters/purlins in metal buildings

-

Retrofit interior lining for garages/shops

-

Furring-strip method to guarantee an air gap

-

Wraps for ducts/pipes (where tape quality is critical)

Tape choice matters. Cheap tape failing after temperature cycling is a common reason “the insulation didn’t work” (because the assembly stops being sealed).

Bulk Buyer Spec Template (copy/paste for your PO)

Use this as a simple procurement checklist:

-

Product name/SKU: ______

-

Facing: foil / metallized film (specify)

-

Core: bubble / foam (specify) + thickness ______

-

Reinforcement: scrim/mesh yes/no

-

Roll size: width ______ x length ______

-

Qty: rolls/pallet ______ | pallet config ______

-

Accessories: foil tape SKU ______ | edge seal needs ______

-

Handling: packaging protection requirement ______

-

Lead time + substitution rules: “No substitutions without approval”

Installation Basics That Decide Results (How to Do It Right)

A “what we commonly see” jobsite anecdote (and the fix)

A frequent real-world scenario: a crew staples reflective rolls tight to framing, skips continuous tape, and expects the interior to cool dramatically. Two weeks later, they say “nothing changed.” When you inspect, the foil is pressed flat (no air gap) and seams are flapping.

The fix that reliably improves outcomes:

-

Add/confirm an air space on at least one reflective face (often via furring or correct placement)

-

Reinstall/retension sections to avoid compression

-

Tape seams continuously and seal edges/penetrations

-

Confirm ventilation paths aren’t accidentally blocked

That’s when reflective insulation starts behaving like a system—not a decorative liner.

Step-by-step (generic, code-agnostic)

-

Plan your air gap location(s).

Prioritize the side facing the dominant radiant source (often the roof deck). -

Keep foil faces uncompressed and reasonably clean.

Compression reduces effectiveness; grime can reduce reflectivity. -

Overlap and tape seams continuously.

Continuous beats spot tape every time. -

Seal edges and penetrations.

Treat penetrations as critical: vents, wiring passes, fasteners, transitions. -

Inspect and repair immediately.

Tears and gaps are cheap to fix during install and painful after finishes go up.

Common mistakes to avoid

-

No air gap

-

Wrong tape (fails under heat/cold cycling)

-

Loose seams or unsealed edges

-

Over-tensioning that tears at fasteners

-

Sealing everything without any plan for moisture/ventilation

Safety & Compliance Notes (Read This Before You Install)

-

Fire documentation: Ask for fire/smoke documentation appropriate to your application and confirm local requirements.

-

Heat sources: Keep reflective materials appropriately separated from high-heat sources per common-sense safety practice and the product’s guidance.

-

Electrical/wiring: Avoid creating unsafe contact points; plan penetrations cleanly and seal without stressing wires.

-

Condensation/ventilation: If you’re in a humid or mixed climate—or you’re dealing with a metal building prone to “sweating”—treat ventilation and moisture paths as part of the design.

-

Local codes vary: Assembly requirements differ by region and building type; confirm compliance for your specific project.

Real-World Use Cases (Anonymized Mini Case Studies)

Case Study 1: Metal garage heat control

Problem: Strong afternoon solar load made the space uncomfortable; the roof radiated heat downward for hours.

Approach: Installed double reflective foil insulation with a maintained air space and fully taped seams.

Outcome: Occupants reported the workspace felt materially less harsh during peak sun, with the biggest improvement being comfort and reduced radiant intensity rather than dramatic HVAC cost claims. A rough field-observed comfort change near the ceiling zone commonly lands in the 5–15°F “feels-like” improvement range when the assembly is done correctly.

Case Study 2: Warehouse / agricultural storage building

Problem: Large interior volume, uneven temperatures near the roofline, and high labor sensitivity.

Approach: Selected tear-resistant roll specs, planned roll widths to reduce seams, and standardized a taping/edge sealing protocol across crews.

Outcome: Better temperature stability near the upper zone and fewer callbacks related to flapping seams or unsealed penetrations. Labor consistency became a major ROI driver.

Sourcing & Supply Notes (Where Wellco Wholesale Fits)

For bulk buyers, “best” means: consistent spec, predictable packaging, and minimal surprises on the jobsite. Wellco Wholesale positions itself as a one-stop factory-direct wholesaler across agricultural, gardening, landscaping, and light building supplies—helpful if you want to consolidate purchasing and maintain steady inventory for repeat projects.

When requesting pricing or planning stock, specify:

-

Facing type + core thickness + reinforcement

-

Roll width/length and preferred pallet configuration

-

Tape/accessory needs for complete installs

-

Lead times and substitution rules (to protect consistency)

Conclusion

Double reflective foil insulation is worth it when your main enemy is radiant heat and you can install it as an assembly: air gap + sealing + moisture awareness. If you treat it like a shiny sheet with no air space, you’re likely to be disappointed.

If you’re buying in bulk, focus on repeatable specs (facing, core, reinforcement, roll map) and make tape/edge sealing part of the package so crews can reproduce the same results job after job.

Frequently Asked Questions

Does double reflective foil insulation replace fiberglass insulation?

Not usually. It’s best as part of an assembly that reduces radiant heat transfer, while fiberglass or other mass insulation handles conductive heat loss/gain. In many builds, they’re complementary rather than interchangeable.

Do I really need an air gap for it to work?

Yes—at least one adjacent air space is what enables the reflective face to reduce radiant heat transfer effectively. If you compress it tightly against a solid surface on both sides, performance usually drops significantly.

Can it help with condensation in metal buildings?

It can, but it can also make condensation worse if installed without a ventilation/moisture plan. Sealed seams and correct assembly details matter, and you should avoid trapping moisture against cold metal surfaces.

What should bulk buyers request to avoid ordering the wrong product?

Request facing type, core thickness, reinforcement, roll size, pallet configuration, and accessory tape SKUs—plus a “no substitutions without approval” note. Consistent specs prevent jobsite surprises and repeat-order confusion.

Is foil tape really that important?

Yes. Seam sealing often determines whether the system behaves like a controlled assembly or a leaky liner. Tape that fails under temperature cycling can undo the performance and create callbacks.