Heat Reflective Foil Insulation: Buyer’s Guide

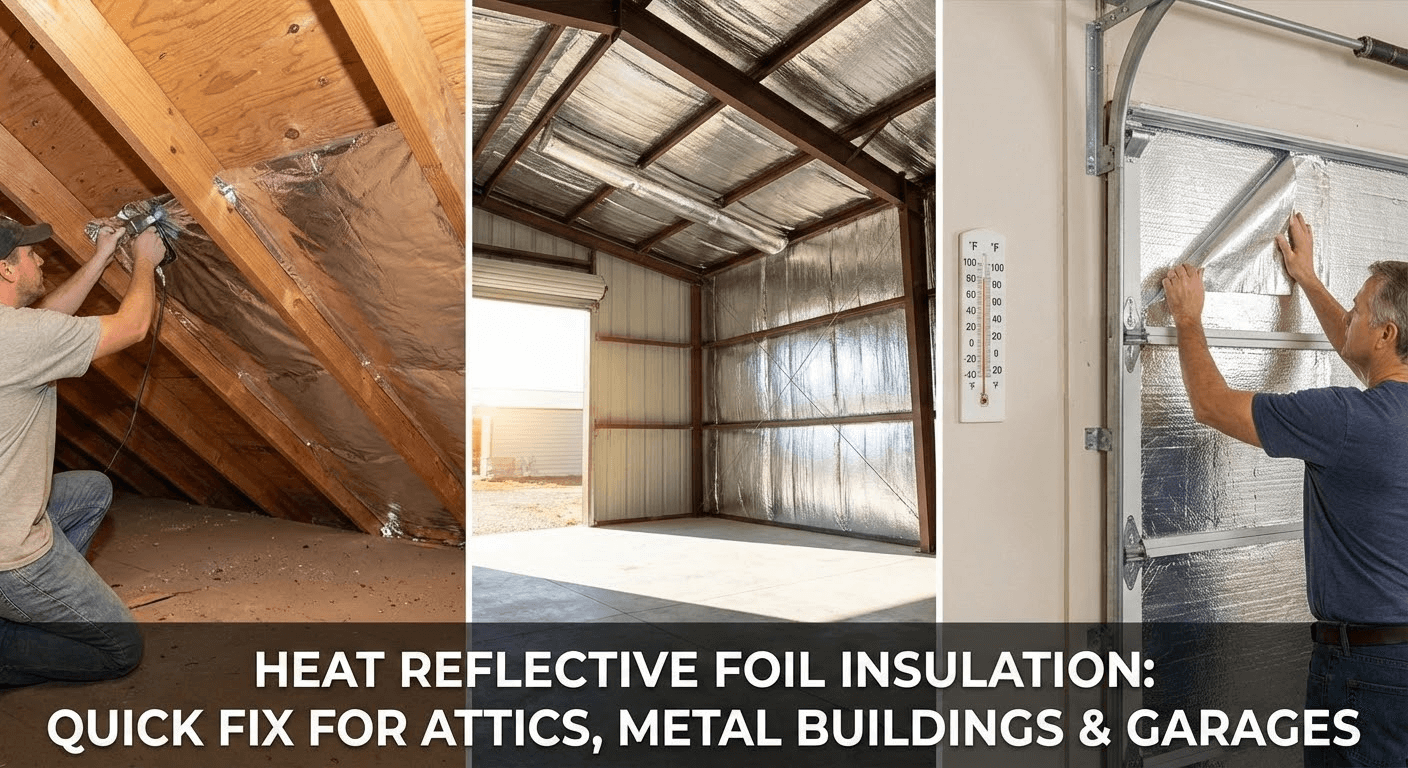

If your attic feels like a broiler, your metal building turns into a solar oven, or your garage is unbearable by mid-afternoon, heat reflective foil insulation is often the first “quick fix” people consider—because it’s lightweight, rolls out fast, and looks like it should work.

It can work—really well—when you understand what you’re buying. This material targets radiant heat, not the “thickness-based” heat loss you solve with fiberglass, mineral wool, or foam. In hot, sunny climates, research cited by the U.S. Department of Energy shows radiant barriers can reduce cooling costs about 5% to 10% in some cases—especially when the attic is a major heat source (and even more so when ducts run through the attic).

For trade customers buying in volume, the real win is also consistency: picking the right product type and installing it the same way across jobs. Wellco Wholesale supports bulk purchasing with a wide range of wholesale garden, farm, landscaping, and light building supplies—handy when you want to source rolls, tapes, and jobsite consumables in fewer orders.

Heat Reflective Foil Insulation Basics

What it is (and what it isn’t)

Heat reflective foil insulation is usually an aluminum foil facing (often reinforced), sometimes bonded to a bubble or foam core. Common formats include:

-

Single-sheet radiant barrier foil (often stapled under rafters)

-

Foil + bubble (single or double bubble)

-

Foil-faced foam (thin foam core with foil on one or both sides)

-

Foil duct/pipe wraps

What it isn’t: a full replacement for bulk insulation. DOE notes that in many cases—particularly outside hot climates—adding more traditional insulation can be more cost-effective than relying on a radiant barrier alone.

Where it tends to perform best

Radiant barriers are typically most effective in hot climates, and DOE specifically calls out attics as a primary use case.

Good matches:

-

Attics (under roof deck / rafters)

-

Metal buildings (roof/wall assemblies with proper detailing)

-

Garages and garage doors

-

Duct/pipe wrap upgrades

-

Some crawlspace scenarios (only with moisture planning)

How Heat Reflective Foil Insulation Works

The air gap is the whole game

Here’s the “I’ve seen this a thousand times” field check: when someone says reflective foil “did nothing,” I can usually find one of these within 30 seconds:

-

the foil is pressed tight to wood or metal (no air space),

-

seams are left open, or

-

the product is being asked to do a bulk insulation job.

Reflective foil needs to face an air space to meaningfully reduce radiant heat transfer. DOE guidance emphasizes this basic requirement: the radiant barrier works when it faces an air space (attic installations are the common example).

Quick rule of thumb

-

Foil facing an air space = radiant benefit

-

Foil sandwiched flat against a surface = big performance drop

Which side faces where

Many products are reflective on both sides, but you still want the reflective surface facing the air space you’re trying to control.

-

Attic: foil faces the attic air space (often attached to rafters).

-

Metal building: foil faces the interior air space; use framing details that preserve spacing.

-

Duct wrap: foil faces outward; seams are sealed to maintain continuity.

Choosing the Right Product for Your Project

Spec Sheet Reading in 60 Seconds

Marketing pages are noisy. Spec sheets are where you win. Here are the numbers and labels that actually matter:

-

Emissivity (ASTM C1371)

-

Lower emissivity generally means better radiant performance.

-

Example: some manufacturer sheets show emissivity values around 0.03 tested to ASTM C1371.

-

Fire performance (ASTM E84)

-

If your application or local code requires it, look for E84 “flame spread” and “smoke developed” ratings on the datasheet.

-

Example: FI-FOIL includes ASTM E84 results on radiant barrier product specifications.

-

Perforated vs non-perforated

-

This affects vapor permeability and moisture behavior. (This matters a lot in metal buildings and crawlspaces.)

-

Reinforcement & durability

-

Reinforced scrims can reduce tearing and callbacks, especially for crews installing at scale.

Use-case match: a simple decision matrix

Attic radiant barrier

-

Best fit: single-sheet radiant barrier foil

-

Why: easy to keep a consistent air space

-

Watch-outs: don’t block ventilation paths

Metal building roof/walls

-

Best fit: reinforced foil products designed for building assemblies

-

Why: durability + better jobsite handling

-

Watch-outs: condensation control is an assembly problem, not a tape problem

Duct/pipe wrap

-

Best fit: rated duct wrap / foil-faced wraps

-

Why: seam sealing and durability matter more than thickness

Garage door comfort upgrade

-

Best fit: lightweight foil-faced kits installed with spacing

-

Why: noticeable comfort change on sun-facing doors

Bulk buying considerations (for trade customers)

If you’re purchasing for crews, resale, or repeat builds, these details save money:

-

Roll size consistency (coverage per roll, palletization)

-

Packaging strength (foil edges damage easily in transit)

-

Tape compatibility (use the tape specified/compatible with the facing)

-

Standard install method (so results don’t vary by crew)

If you’re already sourcing garden/farm/light-building products in volume, consolidating supplies through a wholesale supplier can simplify procurement and standardize materials across job sites.

Installation Guide: Steps, Tools, and Common Pitfalls

Step-by-step (generic but jobsite-real)

Tools

-

Utility knife + straight edge

-

Stapler or cap nails (match substrate)

-

Foil tape rated for the product

-

Measuring tape, marker, PPE

Steps

-

Plan how you’ll preserve the air space. Rafters, furring strips, stand-offs—pick one.

-

Measure and cut cleanly. Jagged edges tear and slow down seam work.

-

Fasten without crushing the system. Don’t “press it flat to make it neat.”

-

Seal seams and penetrations. Continuity matters.

-

Inspect airflow paths. In attics, don’t block soffit/ridge ventilation.

DOE notes radiant barriers are most effective when installed properly in warm, sunny climates—so quality control matters as much as product choice.

Mistakes that most often kill performance

-

No air gap

-

Unsealed seams / tears left open

-

Blocking attic ventilation

-

Wrong tape (fails in heat/dust)

-

Using foil to replace bulk insulation

Moisture & Code Reality Check

Moisture guardrails (especially metal buildings and crawlspaces)

Reflective foil products can function as a vapor retarder depending on construction (especially non-perforated versions). That means you need to think through condensation risk:

-

Don’t trap moisture against cold surfaces.

-

Use ventilation or assembly design appropriate for your climate and building type.

-

Follow manufacturer installation guidance and local building practices.

If you’re unsure, treat this as a “stop and verify” moment: what works in a hot attic may not behave the same way in a cold, humid crawlspace.

Fire & safety basics

-

Keep required clearances from heat sources and follow local code requirements.

-

If a rating is needed, confirm it on the datasheet (ASTM E84 is commonly listed for building materials).

Real-World Performance: What to Expect

The practical outcomes people notice

In the right climate and assembly, the most common “real life” wins are:

-

Less radiant heat felt under the roof

-

Better comfort near ceilings and sun-facing surfaces

-

Peak-summer HVAC load relief (more noticeable during the hottest hours)

DOE cites studies showing radiant barriers can reduce cooling costs about 5% to 10% in some situations.

Anonymized mini case study (generic)

A small metal workshop added reinforced foil under roof framing, maintained a consistent air space, and taped seams carefully. The biggest improvement was afternoon comfort—the “radiant blast” dropped noticeably. The key wasn’t a special product; it was the basics: air gap + seam continuity + not blocking ventilation.

When it’s not enough

If your goal is winter heat retention, sound reduction, or high R-value performance, foil is usually a layer in a system. Many projects pair radiant control (foil) with bulk insulation (fiberglass/mineral wool/foam) to address conduction and convection. DOE also notes that adding traditional insulation can be more cost-effective than radiant barriers in many scenarios.

Conclusion

If you’re buying heat reflective foil insulation, you’ll get better results by thinking like a system designer:

-

Start with the use case (attic vs metal building vs ducts)

-

Protect the air gap (that’s where radiant performance lives)

-

Read the spec sheet fast (emissivity, fire ratings if required, perforation, reinforcement)

-

Install with discipline (seams, penetrations, ventilation paths)

For bulk buyers, standardizing roll sizes, tapes, and an install method can reduce errors and callbacks. And if you’re sourcing multiple categories for ongoing jobs—garden, farm, landscaping, and light building materials—Wellco Wholesale can help streamline purchasing with a broad wholesale catalog.

Frequently Asked Questions

Does heat reflective foil insulation add real R-value?

It can contribute to total performance in specific tested assemblies, but its main job is reducing radiant heat—especially when it faces an air space. For cold-climate or high R-value goals, pair it with bulk insulation.

Do I need an air gap for heat reflective foil insulation to work?

Yes—an adjacent air space is critical for radiant performance. If the foil is pressed tightly against another surface, the radiant benefit drops sharply.

Which side should face outward?

In most setups, you want the reflective surface facing the open air space you’re trying to control (like the attic air). When in doubt, follow the manufacturer installation instructions for your specific product and assembly.

Is it safe to use near heat sources or appliances?

You must follow clearance and code requirements, and use rated products where required. Always check the product datasheet for relevant fire testing (often ASTM E84) and local building rules.

Will reflective foil stop condensation in a metal building?

It can help only when the full assembly is designed correctly (air space, sealing, and ventilation/moisture strategy). Condensation is a moisture management problem—so treat foil as one component, not a guaranteed fix.