low-e reflective foil insulation vs Foam: What Wins?

If your building feels like a heat lamp in the afternoon or a fridge at sunrise, you’re already asking the right question: which insulation strategy fits the physics and the jobsite reality. This guide compares low-e reflective foil insulation vs foam for trade buyers and bulk purchasers, including contractors, facility teams, farm and greenhouse operators, and light building suppliers.

You’ll get a fast decision flow, install do’s and don’ts, a troubleshooting cheat sheet, plus an RFQ spec list you can copy into purchasing. Wellco Wholesale supports one stop, factory direct wholesale buying across agricultural, gardening, landscaping, and light building supplies, which is useful when you want insulation plus the tapes, fasteners, and jobsite consumables to match.

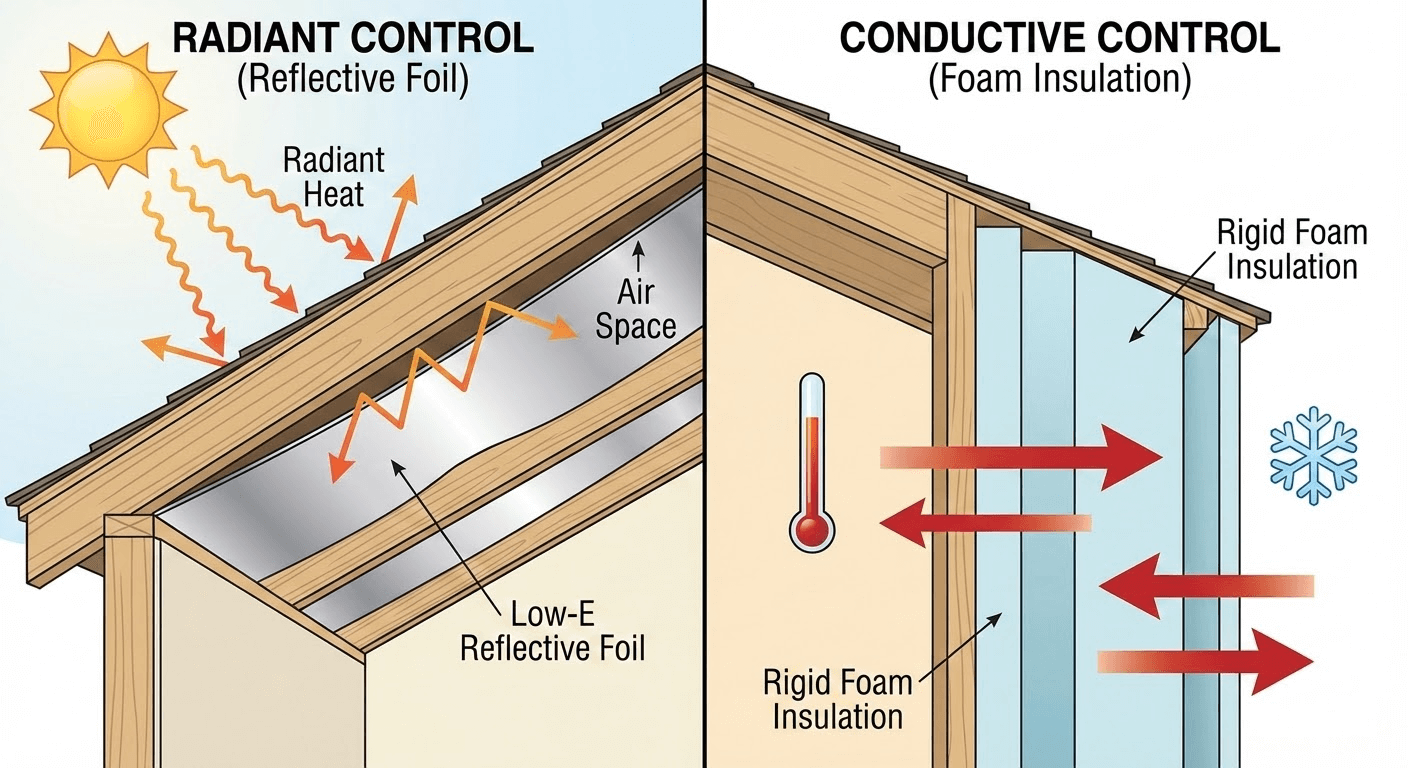

What Low-E Reflective Foil Insulation Actually Does

Reflective foil systems focus on radiant heat. The most important rule is simple and non negotiable: “To be effective, the reflective surface must face an air space.”

That’s why reflective foil often performs best under sun loaded roof decks, metal building roofs, and any assembly where you can preserve an air gap. If the foil is pressed directly against another solid surface, the radiant benefit drops sharply because the heat transfer pathway shifts.

A second key concept is emissivity. A radiant barrier is typically defined as a low emissivity surface (commonly cited as 0.1 or less). Lower emissivity increases radiant heat reduction across the air space it faces.

Quick reality check for buyers:

-

Reflective foil helps most with hot surface radiation into a cavity.

-

It does not replace “bulk insulation” in cold weather scenarios where steady heat loss dominates.

-

It performs like a system: air space, orientation, seams, and penetrations decide outcomes.

Foam Insulation Basics Buyers Should Know

Foam insulation focuses on conductive heat flow. In bulk purchasing you’ll typically choose between rigid foam boards and spray foam depending on geometry, air leakage, and labor availability.

A useful benchmark for decision makers: ENERGY STAR cites EPA estimates that air sealing plus adding insulation can save an average of about 15% on heating and cooling costs (about 11% on total energy costs) for typical existing U.S. homes.

Your project may be commercial or agricultural, yet the point still holds: conduction control and air leakage control can produce meaningful savings when done well.

Where foam tends to shine:

-

Cold season comfort and stable interior surface temperatures

-

Assemblies where thickness is acceptable and continuous coverage is possible

-

Projects where air sealing at transitions is part of the scope

Where foam commonly creates headaches:

-

Retrofits with tight interior clearances

-

Installations with many penetrations and edge conditions that are hard to seal

-

Moisture sensitive assemblies where layering is misplanned

low-e reflective foil insulation vs foam: A 3-Question Decision Flow

Use this as a quick screen before you over analyze.

-

Is the main pain peak afternoon heat from above (hot roof radiating down)?

Reflective foil is often the first lever, assuming you can keep an air space. -

Is the main pain steady heat loss, cold surfaces, or winter drafts?

Foam is usually the foundation material. -

Do you need both summer comfort and winter performance with minimal downtime?

A hybrid approach is common: foam for bulk resistance, reflective foil where radiant gain is driving complaints.

When reflective foil is a bad idea

A university extension resource puts it plainly: if you don’t allow an air space next to the reflective side, the radiant barrier acts like a conductor and passes heat along.

Practical red flags:

-

No way to preserve an air gap at the reflective face

-

High dust environments where the reflective face will quickly foul

-

Assemblies where moisture control requires a different vapor strategy than foil products provide

When foam is a bad idea

Common red flags:

-

Space is tight and required thickness is not feasible

-

The retrofit scope cannot handle the disruption and skilled labor needs

-

You cannot detail transitions and penetrations to prevent air leakage paths

Anonymized field scenario

A small metal warehouse used for packing had strong afternoon heat complaints. The first attempt added foil faced material tight to the roof deck and the difference was modest. The fix was simple: re detail the install to maintain a consistent air space, seal seams, and treat penetrations as part of the system. That change addressed the radiant driver without rebuilding the building, then later phases added targeted foam at problem walls to stabilize winter comfort.

Installation Realities and Troubleshooting

A reflective system can look perfect and still underperform. Details decide performance, and dust is one of the biggest silent killers. The U.S. Department of Energy warns that dust accumulation reduces reflective capability and recommends installing in a way that minimizes dust on the reflective surface.

Older Oak Ridge National Laboratory testing also illustrates the impact: once radiant barriers were dusted in the test setup, cooling load reduction was about 7% compared with the same insulation level without radiant barrier under those conditions.

Best practices for low-e reflective foil insulation

-

Preserve an air gap at the reflective face. Build it into the fastening method and geometry.

-

Face the reflective side toward the air space it is meant to control.

-

Treat seams like a water control layer: compatible foil tape, clean substrate, firm pressure.

-

Detail penetrations: clean cuts, tape edges, avoid leaving “daylight gaps.”

-

Keep reflective faces cleaner longer: reduce open horizontal dust shelves where practical.

Best practices for foam insulation

-

Rigid foam: stagger seams, seal joints, detail edges and corners with compatible tape or sealant.

-

Spray foam: verify substrate condition, control thickness consistency, and plan ventilation and protection.

-

Treat transitions as first priority: roof wall junctions, rim areas, penetrations, doors, and utility paths.

Troubleshooting mini guide

-

Symptom: space feels cooler briefly, then heat returns fast

Likely cause: foil has no air space or major seam leakage

Quick test: inspect for direct contact and open seams at overlaps

Fix: re detail for an air gap, tape seams, seal penetrations -

Symptom: condensation spots at metal members or corners

Likely cause: air leakage carrying moist air to cold surfaces

Quick test: look for airflow paths near junctions and penetrations

Fix: air seal transitions, confirm insulation continuity, review humidity sources -

Symptom: “same product” performs differently across bays

Likely cause: inconsistent detailing, dust exposure differences, missing tape

Quick test: compare seam strategy and air space geometry bay to bay

Fix: standardize kitted materials and install checklist

Safety and compliance considerations

Confirm local code requirements for your building type, especially fire performance, required ignition barriers, and approved use locations. Specify compatible tapes and adhesives and keep install documentation for inspections and maintenance. If the application involves occupied spaces, mechanical rooms, or high temperature equipment, treat material selection and detailing as a safety item, not a value engineering line.

Bulk Buyer Checklist and RFQ Spec Sheet

The Building America Solution Center describes a radiant barrier as reflective foil placed next to an air space to block radiant heat transfer. Use that language in procurement so bidders align with the physics.

RFQ specs for low-e reflective foil insulation

-

Product form: single sided foil, double sided foil, composite

-

Intended install location and which face must face the air space

-

Seam tape requirement: brand compatibility, width, adhesion requirements

-

Roll size, packaging, handling requirements for the jobsite

-

Dust exposure expectations and any protective facing needs

RFQ specs for foam insulation

-

Foam type: rigid board or spray foam

-

Thickness targets by assembly zone and continuity requirements

-

Joint sealing method: tape, sealant, accessories

-

Any compressive strength or durability needs based on use

Bulk logistics that reduce call backs

-

Kit by zone or bay: insulation plus the correct tape, fasteners, and sealants per section.

-

Standardize a short install checklist and require photo documentation of seams and penetrations before cover up.

Wellco Wholesale can support this style of purchasing because buyers often want insulation related supplies bundled with the rest of their agricultural, gardening, landscaping, and light building procurement, reducing multiple vendor coordination.

Conclusion

For low-e reflective foil insulation vs foam, the clean dividing line is radiant control versus conductive control. Reflective foil performs when the reflective face can see an air space and detailing is tight. Foam performs when thickness and continuity are achievable and transitions are air sealed. Many projects land on a hybrid because real buildings have both summer and winter drivers.

Take your next step by writing a one page scope with building type, dominant season pain, whether an air gap is feasible, and install constraints. That single page makes supplier quotes more comparable and reduces mis installs.

Mini glossary

-

Emissivity: how much radiant heat a surface emits; lower means more reflective behavior.

-

Radiant heat: heat transfer by electromagnetic radiation between surfaces

-

Conduction: heat moving through materials by direct contact

-

Air sealing: controlling air leakage paths that drive convective heat and moisture transport

-

Vapor control: managing moisture diffusion and condensation risk through layering and detailing

Frequently Asked Questions

DOE’s baseline rule stays useful even in FAQ form: the reflective surface must face an air space for effectiveness.

-

Can reflective foil replace foam insulation for year round comfort?

Reflective foil targets radiant heat and performs best with an air gap. Foam targets conduction and often supports winter comfort better. Many buildings use both to cover different heat transfer modes. -

What is the biggest reason reflective foil “does nothing”?

Missing or crushed air space is the top cause, followed closely by leaky seams and poorly detailed penetrations. Dust buildup can also reduce reflective performance over time. -

When does foam underperform even if the R value looks right?

Gaps at edges, unsealed transitions, and thermal bridging at junctions can dominate real performance. Consistent detailing and continuity matter as much as the material itself. -

How should bulk buyers reduce installation variability across crews?

Standardize a kit including the correct tapes, sealants, and fasteners, plus a short install checklist. Require photo documentation of seams and penetrations before close in. -

What should I ask for on an RFQ to avoid mismatched products?

For foil, specify form factor, which face must face an air space, and tape compatibility. For foam, specify type, thickness targets by zone, and joint sealing method.