Acoustic Panels to Absorb Sound vs. Foam: Cost & Results

Crisp conversations, focused work sessions, and immersive entertainment all hinge on smart acoustic treatment. Yet many buyers still debate acoustic panels to absorb sound vs. foam—which delivers the bigger payoff? This guide demystifies the choice with hard numbers, real-world outcomes, and hands-on lessons. Wellco Wholesale, a factory-direct wholesaler of building, garden, and hospitality supplies, stocks both solutions in bulk, giving contractors and DIYers an unbiased view of cost, results, and long-term value.

Understanding Sound Absorption Basics

How Sound Behaves Indoors (RT60 & Reflections)

When a clap echoes in a room, the lingering decay—RT60—measures how long sound energy hangs in the air. Classrooms and offices target RT60 ≤ 0.6 s; music studios aim for < 0.3 s. Uncontrolled reflections muddle speech and strain listeners.

Key Performance Metrics (NRC, STC, ASTM & ISO)

-

NRC (Noise Reduction Coefficient): 0 – 1 scale; ≥ 0.85 signals high absorption.

-

STC (Sound Transmission Class): Higher values block more sound through walls.

-

ASTM E84 & ISO 354: Standard fire-safety and absorption tests; Class A surfaces meet the strictest codes.

Acoustic Panels – Materials, Performance & Real-World Results

Core Materials & Constructions

Fabric-wrapped mineral wool, PET felt, and wood-slat hybrids dominate the commercial market. Panels routinely hit NRC 0.90 – 1.05 across the speech band (250 – 4 000 Hz). A 2024 BRS Acoustic Trends Report notes global panel demand grew 8.2 % YoY, driven by hybrid workspaces.

Installation, Maintenance & Aesthetics (Personal Anecdote)

My first DIY install went sideways: I used drywall anchors rated for 4 kg, but a 120 × 60 cm panel weighed 6 kg. One morning it slid off, nicking my monitor. Lesson learned—always verify anchor load and use Z-clips for anything over 5 kg. Since switching, panels have stayed rock-solid, and vacuum cleaning keeps them showroom-fresh.

Case Study: Conference Room Retrofit Cuts Reverberation 45 %

A mid-size tech firm installed 40 m² of 50 mm mineral-wool panels on two walls. Average RT60 fell from 0.78 s to 0.43 s, and video-call clarity scores (internal survey) jumped 30 %. Meeting transcripts needed half the corrections post-upgrade.

Acoustic Foam – Materials, Performance & Limitations

Common Foams & Their NRC Range

Egg-crate and wedge foams post NRC 0.50 – 0.75 for mid-high frequencies but struggle below 250 Hz. Melamine variants reach Class A fire ratings but cost more.

Expert Insight – When Foam Shines

“Foam is an affordable spot treatment for flutter echoes in small rehearsal rooms. Just don’t expect it to tame low-frequency modes,” says Grace Liang, CTS-D acoustical engineer.

Durability, Fire Ratings & Cleaning Concerns

Open-cell foam yellows under UV, crumbles if scrubbed, and traps dust. Many polyurethane grades rate Class B or C in ASTM E84, limiting use in code-regulated venues.

Cost Comparison & Long-Term ROI

Up-Front Material & Installation Costs

| Product | Typical Price /m²* | Average Install Time |

|---|---|---|

| 50 mm Fabric Panel | $28 – 35 | 5 min (clip-on) |

| 50 mm Polyurethane Foam | $10 – 14 | 3 min (spray adhesive) |

| *Bulk pallet pricing, Wellco Wholesale, Q2 2025. |

Lifecycle Costs: Durability, Replacement & Resale

Panels last 15 + years with negligible sag. Foam often needs replacing every 4 – 6 years, doubling lifetime spend.

Budgeting Tips for Trades vs. DIYers

-

Trade buyers: Clip systems slash labor on multi-room projects.

-

DIYers: Use foam for ceilings; reserve panels for high-traffic walls.

Choosing the Right Solution for Your Space

Decision Matrix: Performance × Budget × Aesthetics

| Priority | Recommended Treatment | Rationale |

|---|---|---|

| Highest speech clarity | Panels | NRC ≥ 0.9 across speech band |

| Tight budget / rehearsal | Foam | Cheapest, adequate for practice |

| Hybrid home studio | Panels + foam | Panels at first reflections, foam in corners |

Hybrid Approaches: Combining Panels & Foam Effectively

Mount broadband panels at ear height and apply foam only where flutter echoes persist—cost-efficient yet full-band.

Sourcing & Buying Tips (with Wellco Wholesale Advantage)

Key Questions to Ask Any Supplier

-

Fire rating certificate (Class A?)

-

Core density (mineral wool ≥ 48 kg/m³).

-

Custom sizing, color, or printed branding?

Safety & Compliance Checklist

-

Verify ASTM E84 or ISO 5660 fire-test reports.

-

Check local building code for maximum flame-spread index.

-

Use low-VOC adhesives; follow MSDS for PPE.

-

For public spaces, confirm accessibility clearances after install.

Bulk Purchasing Benefits & Custom Options from Wellco Wholesale

Wellco consolidates manufacturing under one roof, passing an average 12 % cost saving to contractors on full-pallet orders. CNC cutting and dye-sublimation printing turn panels into branded décor that doubles as acoustic armor.

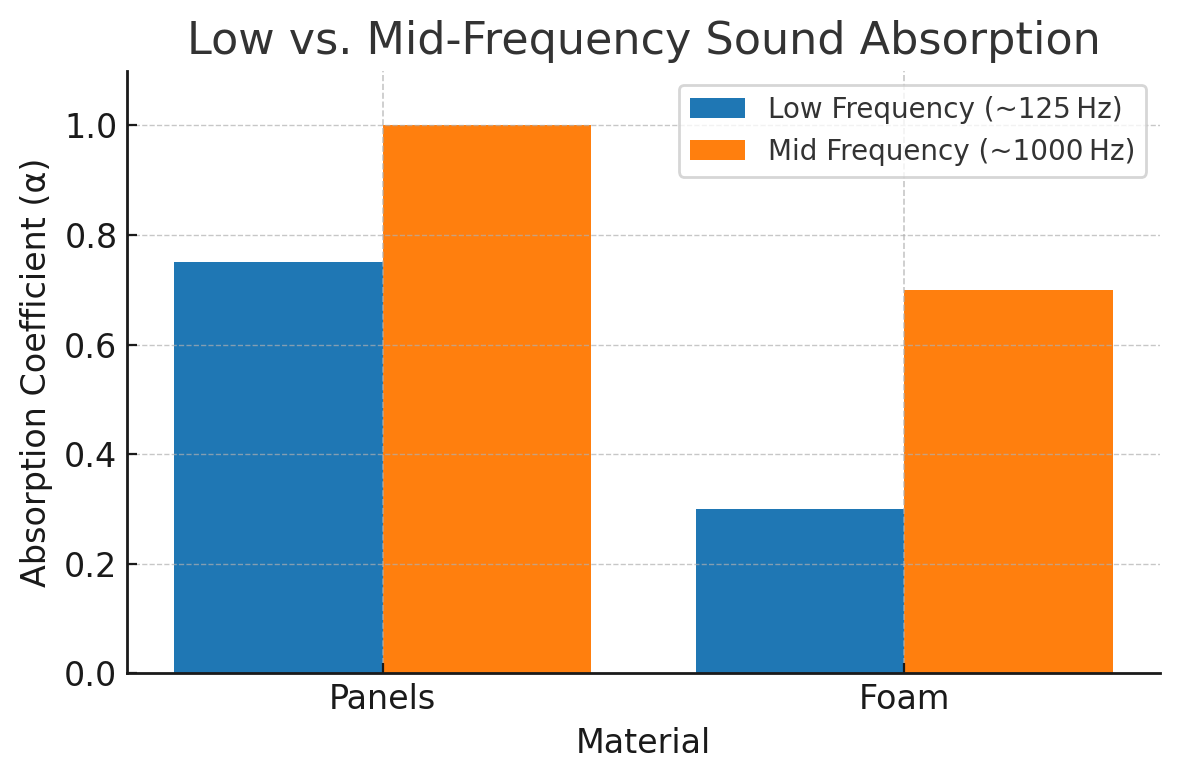

The chart above visualizes how panels outperform foam at bass frequencies while both excel mid-band.

Conclusion

Performance data, lifecycle math, and field experience all point to acoustic panels to absorb sound as the superior long-term choice for professional and high-end residential projects. Foam remains a budget mid-frequency fix, but panels offer full-spectrum control, Class A safety, and 15-year longevity. Whether you need a box or a truckload, Wellco Wholesale stands ready with custom sizes, rapid lead times, and factory-direct pricing—request your tailored quote today.

Frequently Asked Questions

1. How many acoustic panels do I need for a 20 m² office?

Start with 20 – 25 % wall coverage (4 – 5 m²) and test RT60; add panels if speech still feels muddy.

2. Can I paint or print on acoustic panels?

Yes—fabric-wrapped or PET felt panels accept dye-sublimation printing without harming NRC values.

3. Is spray-mounting foam to drywall reversible?

Not cleanly; adhesive often tears drywall paper. Consider removable strips or a lightweight frame instead.

4. Do panels improve soundproofing as well as absorption?

Primarily absorption. For blocking sound between rooms, combine panels with resilient channel and mass-loaded vinyl.

5. Are mineral-wool cores safe indoors?

Certified products are sealed behind fabric; they meet ISO 14001 emissions standards and pose no airborne fiber risk during normal use.