Fiberglass Rebar vs. Steel: Strength, Cost & Disadvantages (2025 Comparison)

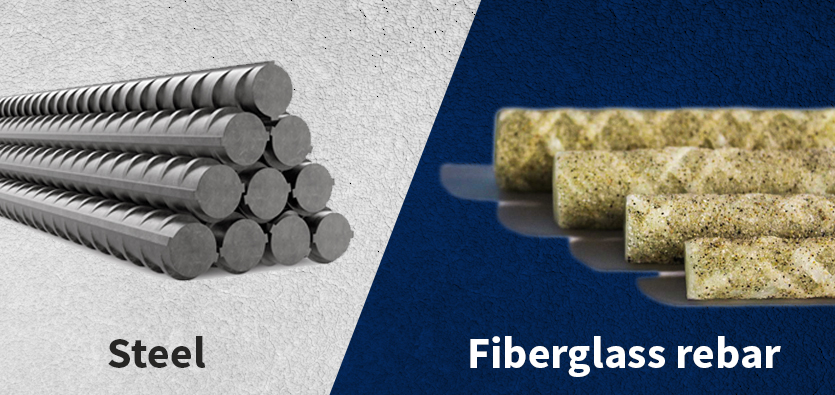

In the world of construction, the debate of fiberglass rebar vs. steel is becoming increasingly common. While steel has been the traditional king of reinforcement, fiberglass (GFRP) is challenging the status quo with superior longevity and strength-to-weight ratios.

Are you wondering "is fiberglass stronger than steel?" or comparing the long-term costs? This 2025 guide breaks down the key technical differences to help you choose the right material for your project.

Quick Comparison: Fiberglass (GFRP) vs. Steel Rebar

| Feature | Fiberglass Rebar (GFRP) | Steel Rebar |

|---|---|---|

| Tensile Strength | Higher (89k - 159k psi) | Standard (60k - 80k psi) |

| Weight | Lightweight (1/4 weight of steel) | Heavy |

| Corrosion | 100% Rust Proof | Prone to Rust |

| Conductivity | Non-Conductive | Conductive |

What is Fiberglass Rebar?

Fiberglass rebar, also known as GFRP (Glass Fiber Reinforced Polymer), is a composite material made from high-strength glass fibers and a polymer resin. Unlike steel, it never rusts. It is lightweight, non-conductive, and designed for environments where traditional steel fails due to corrosion or magnetic interference.

What is Steel Rebar?

Steel rebar is the traditional industry standard made primarily of carbon steel. It relies on its high elasticity and familiarity among contractors. While effective in general construction, it has a fatal flaw: oxidation (rust), which can cause concrete cancer (spalling) over time.

Is Fiberglass Rebar Stronger Than Steel?

Yes, in terms of pure tensile strength. When asking "how strong is fiberglass compared to steel," the numbers speak for themselves:

- Tensile Strength (The Pull Force): Fiberglass rebar (89,900 – 159,500 psi) is roughly 2x stronger than steel (60,000 – 80,000 psi). This makes it an incredible reinforcement for slabs and flatwork.

- Load Capacity & Modulus: Steel still holds an advantage in stiffness. Steel will not bend as much under load before reaching its limit. Fiberglass is more elastic but behaves differently under compression.

Disadvantages of Fiberglass Rebar vs Steel

To make the best decision, you must also know the limitations. Searching for "disadvantages of fiberglass rebar"? Here is what you need to know:

- No Field Bending: Unlike steel, you cannot bend fiberglass rebar on the job site. All bends must be fabricated by the manufacturer (like Wellco Industries) before shipping.

- Lower Shear Strength: While tensile strength is high, its shear strength is lower than steel, which requires specific engineering calculations for beams.

- Initial Cost: The upfront price per linear foot can be higher than black steel, though often cheaper than epoxy-coated or stainless steel.

Cost-Effectiveness: The Long-Term View

Is fiberglass rebar worth the extra investment? Absolutely.

Think about the Lifecycle Cost. Steel rebar may be cheaper upfront, but if your concrete cracks due to rust in 10 years, the repair costs will be astronomical. Fiberglass rebar extends the life of concrete structures significantly, effectively eliminating future maintenance costs.

[Need a Quote?]

Wellco Industries offers factory-direct pricing on bulk GFRP orders. We can customize bends and sizes for your specific project.

Click here to Contact Us for a Quote

Use Cases: When to Choose Fiberglass Over Steel?

We recommend switching to fiberglass rebar for:

- Coastal & Marine Projects: Seawalls, docks, and piers where salt eats steel.

- MRI Rooms & Substations: Where non-conductive and non-magnetic materials are required.

- Chemical Plants: Areas exposed to harsh corrosive elements.

- Driveways & Flatwork: To prevent rust stains and cracking over time.

Conclusion

If your project demands high tensile strength, zero corrosion, and long-term durability, fiberglass rebar is the clear winner. If you need on-site bending or are building a standard structure with low environmental stress, steel remains a solid choice.

Ready to upgrade your reinforcement? Browse our Full Catalog of Fiberglass Rebar available for wholesale.