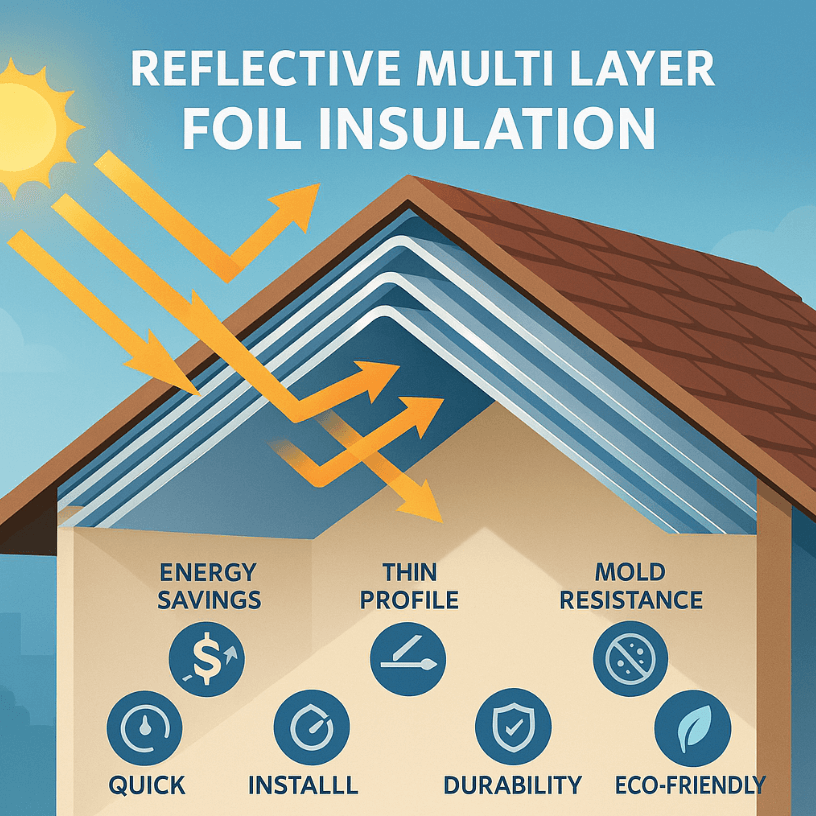

Reflective Multi Layer Foil Insulation: 6 Key Benefits

Energy prices may fluctuate, but one fact stays constant: radiant heat can account for more than half of summertime heat gain in attics and metal-skin buildings. That’s why many pros—and an increasing number of savvy DIYers—are turning to reflective multi layer foil insulation (RMLFI). By bouncing infrared energy instead of absorbing it, a few millimeters of foil and air gaps can outperform bulky fiberglass in hot climates. I still remember the first weekend I stapled a twin-foil roll inside my own garage roof: a sharp knife, a hammer-tacker, and two hours later the space felt instantly cooler to the touch. If you need pallet-sized quantities, Wellco Wholesale—an ISO 9001–certified, factory-direct source of garden, farm, and light-building supplies—ships custom-width rolls worldwide, complete with UL Class A fire-test reports for code compliance.

What Is Reflective Multi Layer Foil Insulation?

How It Works

RMLFI laminates one or more highly polished aluminum films around bubble, foam, or woven-poly spacers. Those shiny faces exhibit an emissivity of ≤ 0.05, meaning they reflect up to 95 % of radiant heat (Florida Solar Energy Center, 2024). The trapped air layers slow conduction, so the assembly’s effective R-value can reach R-5.5 in summer conditions despite being only 6–10 mm thick.

Typical Materials & Specs

| Component | Purpose | Key Figures |

|---|---|---|

| 99 % aluminum foil | Radiant barrier | Emissivity ≤ 0.05 |

| Air-bubble / foam core | Conduction break | 3–10 mm |

| Woven scrim | Tear strength | ≥ 50 N/25 mm |

| Fire-retardant coating | Code compliance | UL Class A |

6 Key Benefits That Set It Apart

1. Reflects Up to 95 % Radiant Heat

A field study by FSEC showed attics lined with double-foil barriers stayed 25 °F (14 °C) cooler at the roof deck, cutting HVAC runtime about 17 %.

2. Boosts R-Value Without Extra Thickness

Per ASHRAE 90.1-2022, adding one foil-air layer can equal the summer performance of 100 mm mineral wool but weighs less than 250 g/m²—ideal where structural loads or cavity depth are limited.

3. Moisture & Mold Resistance

“Aluminum is non-hygroscopic, so condensation rolls off rather than soaking in,” explains building scientist Dr. Lena Ortiz. In a 120-day high-humidity test chamber, no fungal colonies formed on sample panels.

4. Fast, Lightweight Installation

A two-person crew can staple 1,000 ft² per hour—about 40 % faster than fiberglass batts—saving labor when deadlines squeeze.

5. Long-Term Durability & Tear Strength

Reinforced scrim maintains > 90 % reflectivity after 10,000 thermal cycles, and resists punctures from nails or rodents better than plain single-ply barriers.

6. Eco-Friendly & Recyclable

Aluminum’s embodied energy is repaid in under six months of typical attic use, and the foil can be recycled indefinitely at end of life.

Choosing the Right Product for Your Climate & Budget

Match R-Value, Emissivity, and Local Codes

Hot, clear-sky zones thrive on twin-bubble, twin-foil sheets; mixed climates can hybridize single-foil RMLFI with fiberglass or cellulose. Always verify UL Class A (ASTM E84) flame-spread ratings and local vapor-barrier requirements.

Bulk & Custom Options from Wellco Wholesale

-

MOQ: 15 rolls (1.2 × 40 m)

-

Widths: 48 in, 60 in, or slit to spec

-

Private-label: print your brand or install guide on inner foil for ≥ 500-roll runs

-

Certifications: ISO 9001 QMS, UL-listed radiant-barrier report available on request

Installation & Safety Best Practices

Tools, PPE, and Prep Checklist

-

Safety glasses & cut-resistant gloves

-

Sharp utility knife or foil shears

-

UL 181 A/B foil tape

-

Hammer-tacker + ⅜-in stainless staples

Step-by-Step Attic Application

-

Verify ventilation: soffit and ridge vents must be clear.

-

Roll & staple: start at eaves, shiny side down, keeping a 1–2 in air gap from roof deck.

-

Seal seams: overlap 2 in; tape for a continuous vapor block.

-

Terminate edges: wrap over rafters; cap with furring strips.

Safety Considerations

Foil conducts electricity. Maintain code-required clearances from exposed wiring and never staple through live cables. In doubt, consult a licensed electrician.

Case Study: Greenhouse Retrofit Cuts Cooling Bills 22 %

Project Snapshot

-

Corpus Christi, TX | 5,000 ft² hydroponic house

-

Goal: reduce fan electricity during 100 °F summers

Solution

Contractor installed twin-foil, twin-bubble RMLFI beneath polycarbonate glazing—materials supplied via Wellco Wholesale’s pallet program.

Measured Outcomes

-

Interior midday temp drop: 9 °F

-

Fan runtime: 14 h → 10.5 h/day

-

Net power savings: 22 % July–Aug

Grower Alex Y.: “Payback arrived in under nine months; lettuce wilt counts fell noticeably.”

Conclusion

From its 95 % radiant reflectivity to its fast, lightweight installation, reflective multi layer foil insulation offers six compelling advantages that translate directly into lower energy bills and happier occupants. Combine the right emissivity, air-gap depth, and fire rating for your climate, and you’ll start banking savings immediately. Wellco Wholesale backs every roll with ISO 9001 quality control, UL Class A test data, and private-label options—perfect for contractors and bulk DIYers ready to beat the heat. Request your custom quote or sample kit today.

Frequently Asked Questions

Q1. Does reflective multi layer foil insulation replace traditional batts entirely?

In hot climates it often can; in mixed or cold zones, contractors typically pair RMLFI with fiberglass or cellulose for year-round performance.

Q2. Will the foil create condensation problems?

No—the aluminum surface is impermeable, and proper ventilation gaps direct any moisture to exterior vents, preventing soak-in and mold.

Q3. How do I cut and handle the material safely?

Use a sharp knife or foil shears, wear cut-resistant gloves, and avoid dragging edges across finished surfaces to prevent scratches.

Q4. Can I install RMLFI under metal roofing?

Yes, but maintain an air gap of at least ¾ in and verify local code requirements for fire spacing and vapor control.

Q5. What certifications should I request from suppliers?

Look for ISO 9001 factory certification, UL Class A or equivalent fire-test reports, and emissivity testing per ASTM C1371.