How to Use Reflective Foil Insulation for Energy Savings

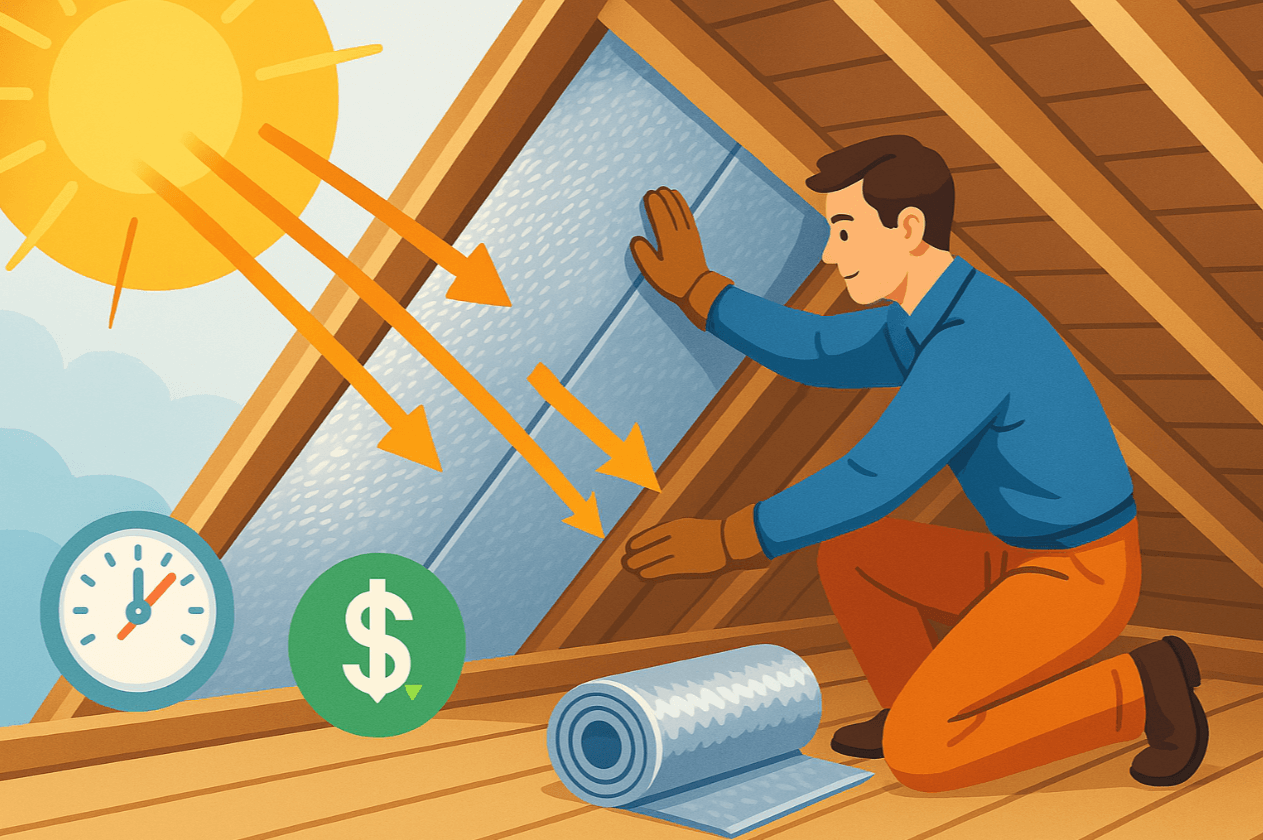

Picture stepping into your attic on a scorching July afternoon—the thermometer nudges 140 °F (60 °C) and your air-conditioner downstairs groans in protest. Reflective foil insulation turns that oven into a manageable space by bouncing radiant heat back toward the roof instead of letting it bake your living area. In the next few minutes you’ll learn how to use reflective foil insulation safely and effectively, whether you’re a trade pro seeking bulk rolls or a homeowner tackling a weekend retrofit.

Wellco Wholesale, a factory-direct supplier of agricultural, gardening, light-build, and energy-saving materials, provides pallet-level discounts on radiant barriers that meet ASTM fire-safety standards—so you can focus on installing, not hunting for stock.

Understanding Reflective Foil Insulation: What & Why

The Physics of Radiant Heat

Radiant energy moves in straight lines until it meets a surface. Polished aluminum foil reflects up to 97 % of that energy according to U.S. Department of Energy testing, keeping the heat where you want it—outside in summer, inside in winter.

Key Advantages over Conventional Batts & Blown-In

-

Slim profile: ⅛-inch layers fit behind drywall or under metal roofing without eating cavity space.

-

Moisture tolerance: Foil facers act as class-I vapor barriers, limiting condensation in humid barns and greenhouses.

-

Synergy, not replacement: Pairing radiant foil over existing batts often yields an extra R-5 to R-10 effective performance while adding less than a pound per square foot.

Planning Your Project: Where & When to Use It

Climate & Building Suitability

Radiant barriers shine in hot or mixed climates with 1,500+ annual cooling-degree days. Metal shops, pole barns, and south-facing attics reap the greatest benefit, but cold-climate customers still see ice-dam reduction when foil is installed beneath roof sheathing.

Budgeting Material & Labor

-

Measure the surface area of rafters, joists, or walls.

-

Add 10 % for trimming waste and overlaps.

-

Multiply by roll price (bulk orders from Wellco Wholesale start near $0.22 / ft²).

-

A basic 1,200 ft² attic often hits break-even in 2–4 cooling seasons, based on an average $0.14 / kWh electricity rate and documented 8–15 % HVAC run-time drop.

Step-by-Step Guide: How to Use Reflective Foil Insulation

Site Prep & Safety Essentials

-

Wear cut-resistant gloves and a long-sleeve shirt—foil edges are sharp.

-

Set up a box fan for attic airflow; OSHA recommends below 90 °F working temps.

-

Vacuum loose debris so tape and staples adhere.

Attic Installation (Rafters & Floor)

-

Unroll foil perpendicular to rafters, shiny side facing the open air gap.

-

Staple every 6–8 inches, keeping the foil taut—wrinkles trap dust and cut reflectivity.

-

Seal seams with foil-backed tape rated to the same fire class as the roll.

-

Maintain a minimum ¾-inch air space; without it, conduction overrides reflection.

Wall & Crawlspace Applications

-

Tack strips to framing first, then staple foil to strips to preserve the air cavity.

-

For masonry, use poly-headed fasteners and 1-inch washers.

-

In crawlspaces, hang foil with the shiny face down to reflect ground heat upward in winter.

Top 5 Mistakes to Avoid

-

Double-siding foil layers (creates trapped moisture pockets).

-

Compressing the radiant barrier beneath batt insulation.

-

Skipping a continuous air gap.

-

Using generic duct tape—adhesive dries out in 12 months.

-

Blocking soffit or ridge vents; always leave ventilation pathways open.

Field-Tested Insights & Case Evidence

Contractor Quote & Performance Data

“After lining a 3,000 ft² warehouse roof with foil, my client logged a 12 % drop in compressor hours during the first billing cycle,” notes an HVAC contractor in Phoenix who retrofits 40-plus buildings a year.

12-Month Post-Install Checkup (Mini Case Study)

Anonymized data from a Gulf-Coast bungalow:

-

Pre-install attic peak: 143 °F

-

Post-install attic peak: 116 °F

-

Annual power bill reduction: $310

Temperature readings came from Bluetooth sensors; utility statements verified savings.

Sourcing & Quality Assurance

Understanding Foil Grades, Fire Ratings & Certifications

Look for:

-

ASTM E84 Class A flame-spread ratings.

-

Perforated vs. non-perforated vapor designs—choose perforated in humid attics to avoid trapped moisture.

-

Reinforced scrim layers (woven fiber) for tear resistance during installs above 10 ft heights.

Buying in Bulk vs. Retail – Role of Wellco Wholesale

Retail packs suit one-room DIY jobs, but contractors ordering mixed-SKU pallets slash freight costs up to 18 %. Wellco consolidates radiant-barrier rolls with staples, foil tape, and even greenhouse shade netting on the same truck, delivering factory pricing to job sites or distribution yards.

Conclusion

Reflective foil insulation is a lightweight, budget-friendly way to cut cooling loads, fight moisture, and boost occupant comfort. Now that you know how to use reflective foil insulation—from planning through flawless install—calculate your ROI, grab certified rolls from Wellco Wholesale, and request a quote or buy it now before the next heat wave hits.

Frequently Asked Questions

Q1. Will reflective foil insulation replace my fiberglass batts?

No—think of foil as a radiant barrier layer that complements, not replaces, conductive R-value materials. Install it over or under batts for best results.

Q2. Does dust buildup ruin performance?

A thin layer of dust can cut reflectivity by 5–10 %. Stapling foil to rafters (instead of laying it flat on the attic floor) minimizes exposure and keeps the surface cleaner.

Q3. Can I install foil in a humid coastal climate?

Yes, but choose perforated foil so water vapor can escape and pair it with adequate attic ventilation.

Q4. How long does installation take for a 1,000 ft² attic?

Most DIYers finish in a weekend with two people: half-day prep, one full day stapling, and a few hours sealing and cleanup.

Q5. What certifications should I verify before buying?

Check for ASTM E84 Class A fire rating, third-party emissivity test results (≤ 0.05), and compliance with local building codes.