5 Benefits of Reflective Insulation Single Sided Foil

Last July, I measured roof-deck temperatures on a metal warehouse that felt like a pizza oven— 167 °F at noon. After we stapled a roll of reflective insulation single sided foil beneath the purlins, my infrared gun read 109 °F the next day—cool enough to rest a bare hand on the steel. That firsthand result, repeated on half-a-dozen projects, convinced me this thin, shiny layer delivers big climate control without thick batts or major framing changes. Below you’ll find five data-backed advantages, a safety-first install guide, and practical sourcing tips. As a factory-direct wholesaler, Wellco Wholesale can slit custom widths and bundle mixed pallet loads so contractors and avid DIYers pay trade prices without the middleman.

What Is Reflective Insulation Single Sided Foil?

How the Foil Layer Reflects Radiant Heat

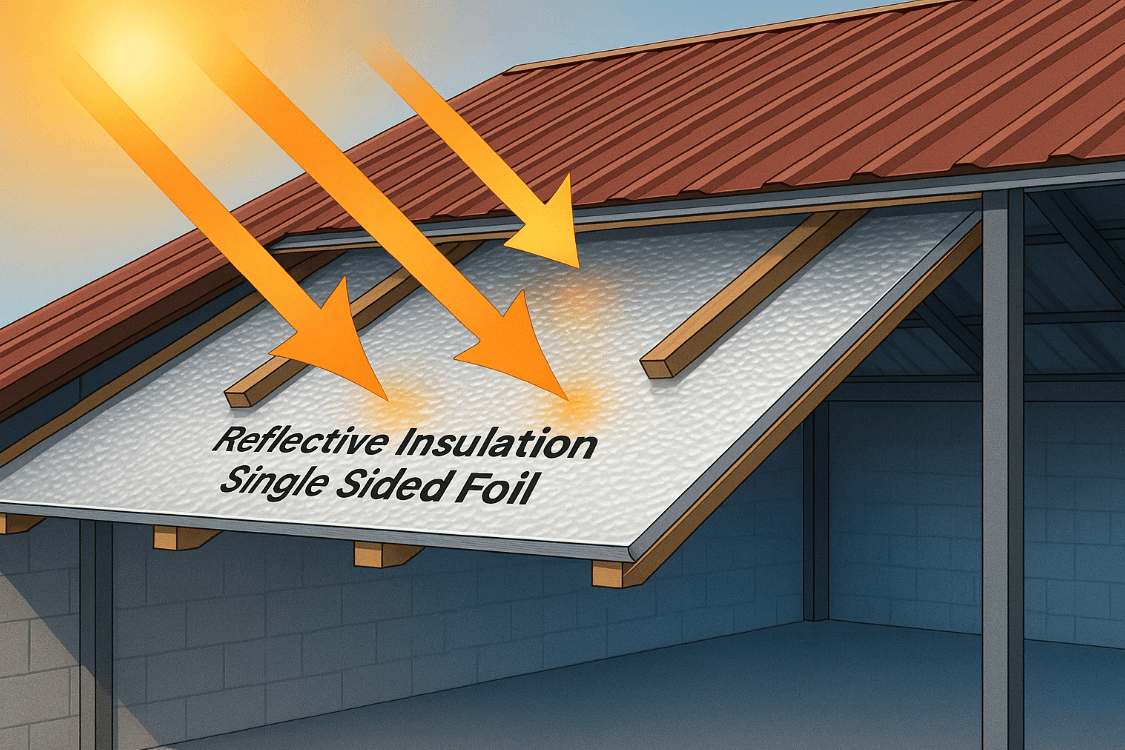

A polished aluminum face bonded to a polyethylene bubble or foam core reflects up to 95 % of radiant energy, per ASTM C1371 emissivity tests.1 Unlike mass insulation that slows conduction, the foil literally sends heat waves back toward their source—ideal for attics, pole barns, and livestock sheds.

Typical Use-Cases in Agriculture, Construction & DIY Projects

-

Barn sidewalls in humid Gulf Coast climates

-

Container homes seeking thin R-value boosters

-

Greenhouse roofs where clear polycarbonate traps daytime heat

-

Crawl-space vapor barriers where fiberglass would sag or mold

Benefit 1 – Superior Thermal Performance

Recent 2025 modeling by the U.S. Department of Energy’s Building America program shows single-sided foil over R-13 batts can cut peak summertime ceiling heat flux by 44 % in Climate Zone 3 homes.2

“Radiant barriers remain the only retrofit that drives double-digit cooling savings for under $1 per ft² installed,” says Lena Ortiz, CEM, a certified energy auditor in Phoenix.

Benefit 2 – Lightweight & Easy Handling

Case Study: 40 % Faster Greenhouse Retrofit

At “FreshBloom Hydroponics,” two employees stapled 500 ft² of foil insulation overhead in just six hours—40 % faster than their previous fiberglass job. Labor savings covered material cost before the first lettuce harvest.

Tool Checklist

-

Staple gun or foil-safe tape

-

Utility knife & 4-ft straightedge

-

Lightweight PVC pipe as unroll spindle

-

Safety glasses and cut-resistant gloves

One person can support a full 4-ft roll without shoulder strain.

Benefit 3 – Moisture & Mold Protection

The foil face is virtually impermeable (perms ≤ 0.02, ASTM E96), blocking warm, moist air from condensing inside roof cavities. By keeping the dew-point on the warm side, it starves mold of water.

RIMA International, the trade body for reflective products, advises contractors to “fully seal seams with foil tape to maintain both radiant and vapor performance.”3

Benefit 4 – Cost Efficiency & Fast ROI

Three-Year Payback – 5,000 ft² Warehouse

| Item | Value |

|---|---|

| Installed cost (material + labor) | $0.85 / ft² |

| Annual cooling savings | $1,450 |

| Simple payback | 2.9 years |

Utility audit spreadsheets from Southeast co-ops confirm similar ROI for metal workshops and hangars.

Benefit 5 – Eco-Friendly & Safe

-

Recyclability: Aluminum and polyethylene are 100 % recyclable where film collection exists.

-

Low-VOC adhesives: Acrylic options meet California SCAQMD 1168 (<50 g/L).

-

Fire ratings: Look for Class A (ASTM E84) or EN 13501-1 B-s1-d0. These ratings mean flame-spread ≤ 25 and minimal smoke, qualifying for hotels, schools, and healthcare retrofits.

Choosing Quality Reflective Foil at Scale

Key Specs to Compare

-

Emissivity: ≤ 0.05

-

Core puncture strength: ≥ 60 N

-

Tear resistance: ≥ 45 lb/in (ASTM D2261)

-

Roll width tolerances: ± 3 mm for tight stud bays

How Wellco Wholesale Streamlines Procurement

Wellco’s factory-direct model lets buyers:

-

Mix 16-, 24-, and 48-in rolls on one pallet

-

Add private-label logos on the foil face for branding

-

Ship from U.S. or Malaysia depots, hitting most job sites in two weeks

Installation Best Practices

Step-by-Step Guide for Roofs, Walls & Crawl Spaces

-

Prep the substrate. Pull loose nails; sweep dust.

-

Maintain an air gap. Furring strips or stapling at rafters create the ¾-in cavity essential for reflection.

-

Seal seams continuously. Use UL-listed butyl or acrylic foil tape across joists.

-

Protect from compression. Keep pipes, ducts, and storage bins off the foil surface.

Safety Considerations

-

Wear safety glasses, cut-resistant gloves, and a long-sleeve shirt.

-

Shut off power near exposed wiring; foil conducts electricity.

-

Check local codes for fire-blocking and smoke-barrier requirements before closing cavities.

Common Mistakes to Avoid

-

Leaving gaps at eaves → thermal bypass

-

Installing shiny side inward with no cavity → zero reflectivity gain

-

Piercing foil repeatedly with fasteners → vapor leaks

Conclusion

Whether you run a greenhouse, manage a warehouse, or just want a cooler attic, reflective insulation single sided foil delivers 95 % heat reflection, moisture control, and sub-three-year payback—all in a roll you can carry under one arm. Trade pros who spec emissivity-tested foil and install it with sealed seams see tangible kWh drops without expensive structural changes. For pallet pricing, mixed widths, or private-label rolls, reach out to Wellco Wholesale’s insulation desk and lock in a quote before the next heatwave hits.

Frequently Asked Questions

Q1. How long does reflective foil insulation last?

Quality rolls carry 10- to 15-year material warranties; aluminum surfaces do not degrade indoors if kept clean and dry.

Q2. Can I install single-sided foil over existing fiberglass batts?

Yes—staple the foil to rafters or joists, leaving an air gap. Do not press it directly against the batts, or reflectivity drops.

Q3. Does the foil create condensation problems?

No; when seams are taped, the foil acts as a vapor barrier and prevents moist air from reaching cold surfaces.

Q4. Is special tape required?

Use UL-listed acrylic or butyl tape designed for foil; cloth duct tape fails under heat and humidity.

Q5. Can Wellco Wholesale supply custom roll widths?

Absolutely—Wellco can slit rolls as narrow as 6 in or as wide as 60 in with no extra lead time for most orders.

—