Reflective Foil Bubble Wrap Insulation vs. Foam

Choosing between reflective foil bubble wrap insulation (RFB) and foam is not a simple “what’s the highest R-value?” question. It’s a decision about heat transfer modes, condensation risk, installation realities, and code triggers. This guide compares how each system works, where each wins, and when a hybrid delivers the best comfort per dollar.

Who it’s for: contractors, facility managers, ag/pole-barn builders, and serious DIYers weighing cost, moisture control, and code compliance.

About sourcing: Wellco Wholesale is a factory-direct supplier for trade and retail buyers—bulk rolls, rigid foam boards, tapes, butyl, fasteners, and custom slitting/pallet programs—so you can spec once and avoid mid-install change orders.

Expert insight: “Radiant layers only work as intended when they face an air space; no air gap, no radiant performance.”

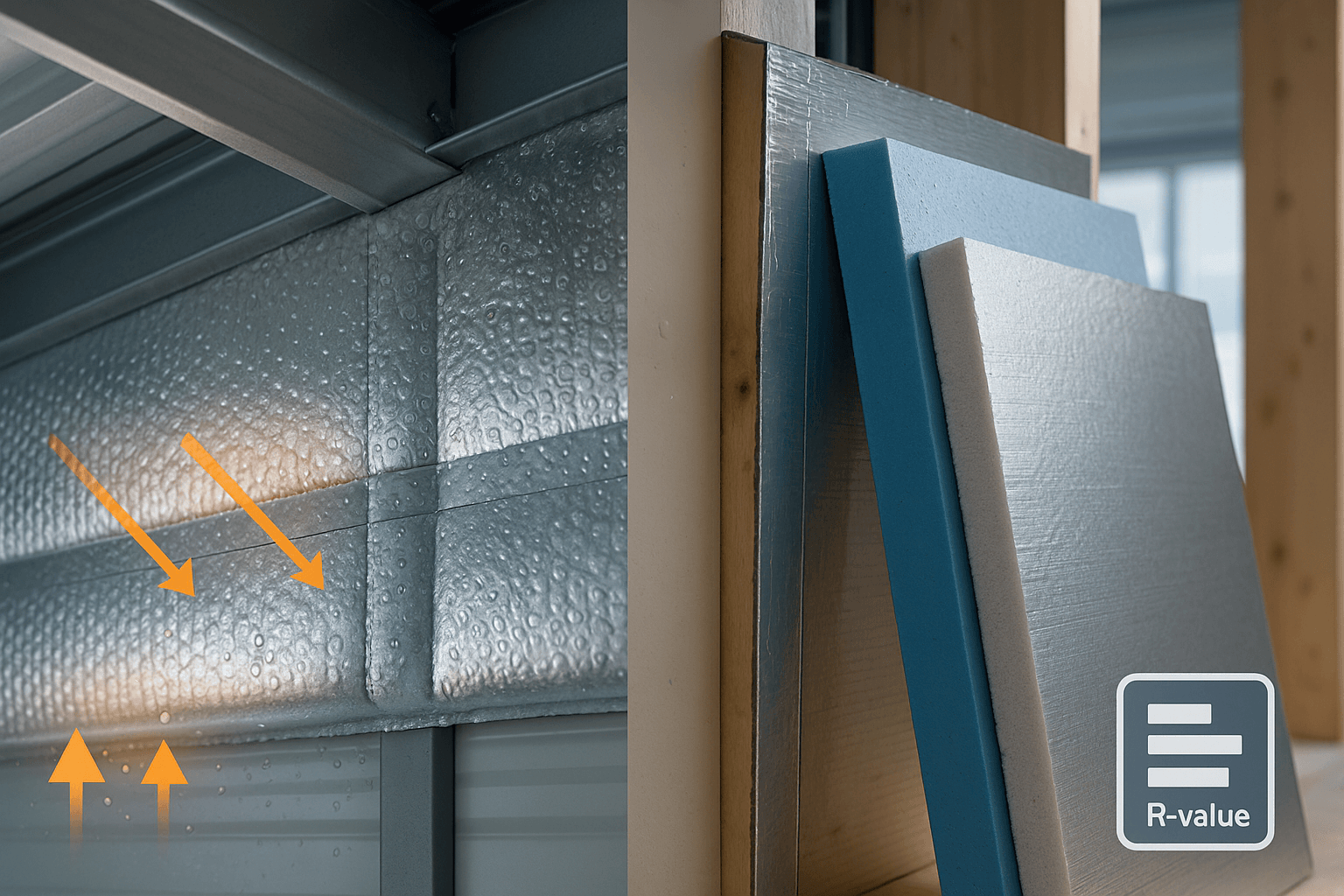

How Reflective Foil Bubble Wrap Works

Composition & Mechanism

RFB is one or two layers of polyethylene bubbles laminated to low-emissivity aluminum facers (often with reinforcing scrim). The foil surfaces reflect long-wave radiant energy (typical emissivity ~0.03–0.05), and the facer typically serves as a low-perm vapor retarder. Performance depends on an adjacent air gap; press it hard to a solid surface and you lose most of the radiant benefit.

Where It Excels

-

Metal buildings & pole barns: cuts radiant gain and stops roof dripping by warming the interior metal surface.

-

Garages, shops, vans/containers, ducts: clean, light, fast installs with minimal mess.

-

Retrofits: easy to staple/strap below purlins or rafters without demo.

Field rule: “If you can’t maintain a gap, plan for foam.”

How Foam Insulation Works

Types & Typical Properties

-

EPS: ~R-3.6–4.2/in, vapor-open, stable, economical.

-

XPS: ~R-4.5–5.0/in, moisture-resistant, higher compressive strength.

-

Polyiso (often foil-faced): ~R-5.6–6.5/in (check cold-weather derating).

-

Spray foam: open-cell (air seal, vapor-open) vs. closed-cell (~R-6–7/in, air + vapor control, adds stiffness).

Foam delivers predictable conductive R/inch regardless of air space, and when seams and edges are treated, it also reduces air leakage.

Side-by-Side Comparison (Quick Reference)

| Attribute | Reflective Foil Bubble Wrap | Foam Boards / Spray Foam |

|---|---|---|

| Primary function | Radiant control + vapor retarder | Conductive R-value + air control (when sealed) |

| Needs air gap? | Yes (to realize radiant benefit) | No |

| Typical thickness | Single ~3/16" (≈5 mm); Double ~5/16" (≈8 mm) | Variable; choose to hit target R |

| Emissivity (foil) | ~0.03–0.05 | N/A (unless foil-faced polyiso surfaces used for radiant layers) |

| Vapor behavior | Usually low-perm (retarder) | Ranges from low-perm (foil-faced polyiso, closed-cell SPF) to higher-perm (EPS, open-cell SPF) |

| Best fits | Metal roofs/walls, pole barns, duct wrap, vans | Code-driven R targets, continuous insulation, below-grade, complex air-sealing |

| Labor profile | Fast in open spans; minimal cutting | Cut-and-fit (boards) or specialized crew (spray) |

| Common pitfalls | Crushed bubbles, no air gap, untaped seams | Gaps at seams/edges, ignition/thermal barrier requirements |

Performance Reality: “R-Value” vs. Results

-

Radiant vs. conductive: RFB primarily reduces radiant exchange and surface condensation; foam primarily reduces conductive losses and, when detailed, air leakage.

-

Myth vs. Fact:

-

Myth: “One layer of bubble wrap equals R-6 anywhere.”

Fact: Any “assembly R” figures for RFB include the effect of adjacent air layers and orientation; you can’t compare those numbers directly to foam’s material R/inch. -

Myth: “Radiant barriers replace continuous insulation.”

Fact: They complement insulation; foam is still required where code sets minimum R.

-

-

Thermal bridging: Foam used as continuous insulation can recover 10–20%+ whole-assembly losses that occur through studs/rafters.

Moisture & Condensation Control

Vapor Strategy & Dew Point

In cold climates, interior moisture drives outward; in hot-humid, inward. Both RFB and foil-faced polyiso are low-perm—great for controlling interior condensation at metal skins, but you must place the vapor layer correctly for your climate and ensure seams are airtight.

Worked example (conceptual):

Interior 68 °F at 45% RH → dew point ≈ 45 °F. In a Zone 5 winter (design ~10–15 °F), an uninsulated metal roof can easily drop below 45 °F, causing drip. Adding RFB with a maintained air gap raises the interior metal surface temperature and blocks vapor—drip stops. If the space is conditioned to code levels, add continuous foam so the condensing surface stays above dew point inside the assembly.

Installer Tips

-

Run layers continuous; tape and roll all seams.

-

Flash penetrations; bridge RFB to wall layers for a continuous air/vapor boundary.

-

For foam boards, seal edges and use compatible adhesives/fasteners.

Standards & Test Methods (Callout)

-

Emissivity / Reflectance: ASTM C1371

-

Thermal Resistance (materials): ASTM C518

-

Surface Burning (flame/smoke): ASTM E84

-

Water Vapor Transmission: ASTM E96

Tip: Ask vendors for current test reports, not just marketing sheets.

Climate & Use-Case Decision Matrix (IECC Zones 1–8)

| Use-Case ↓ / Climate → | 1–3 (Hot to Warm) | 4 (Mixed) | 5–6 (Cold) | 7–8 (Very Cold) |

|---|---|---|---|---|

| Metal building (unconditioned) | RFB for radiant + drip | RFB | RFB | RFB |

| Metal building (conditioned) | Hybrid (RFB + foam CI) | Hybrid | Foam CI (+ optional RFB) | Foam CI (+ optional RFB) |

| Garage/Shop conversion | Hybrid | Foam CI | Foam CI | Foam CI |

| Van/Container | RFB + targeted thin foam | Hybrid | Hybrid | Hybrid |

| Attic retrofit | RFB (radiant layer) + code attic R | Hybrid | Foam at deck + attic R | Foam at deck + attic R |

CI = Continuous Insulation. Always verify local amendments.

Case Study (Anonymized, Pole Barn)

A 3,000 sq ft pole barn had winter roof drip. We stapled double-bubble foil below purlins, holding a ~¾" air gap, and taped all seams.

Before: frequent drip on cold mornings; interior metal ~5–10 °F above ambient.

After: visible drip stopped; interior metal ran ~12–18 °F above ambient on sunny winter days; crew noted quicker morning warm-up. A second bay later received 1.5" foil-faced polyiso (sealed seams)—higher comfort and shorter heater runtimes, but higher material + install time.

Crew anecdote: “Pre-cut lengths and strap spacing at 24 in. o.c. cut our roof-bay time from ~22 min to ~14 min—big win on a 60' span.”

Installation, Labor & Tools

RFB (Staple/Strap)

-

Pre-cut; keep a consistent air gap.

-

Staple or strap; don’t crush bubbles.

-

Tape and roll seams; flash penetrations.

Typical labor: ~0.6–1.0 min/sq ft in open spans.

Foam

-

Boards: cut-and-fit, adhesive + fasteners, tape seams; add ignition/thermal protection if required.

-

Spray foam: substrate clean/dry, lift control, trim, required coatings or coverings.

Typical labor: boards ~1.5–3.0 min/sq ft; spray ~0.8–1.5 min/sq ft plus masking/ventilation.

Fire, Safety & Compliance

-

Verify ASTM E84 ratings (Class A options available for many facers).

-

Spray foam often requires an ignition or thermal barrier (e.g., intumescent coating or gypsum) per IRC/IECC—check local amendments.

-

PPE: cut-resistant gloves for foil edges, eye protection; for spray foam, follow manufacturer ventilation and cure guidance.

-

Exposure: Most foils aren’t UV-rated for long-term exposure.

Cost, Availability & Sustainability

-

Material ranges (indicative, varies by region):

-

RFB rolls: $0.30–$0.90/sq ft (spec & reinforcement dependent).

-

Foam boards per inch: EPS $0.40–$0.80, XPS $0.70–$1.30, Polyiso $0.60–$1.10 per sq ft.

-

Closed-cell spray foam (installed): $1.00–$2.00 per board foot (1 in × 1 sq ft).

-

-

Sustainability notes: choose low-GWP blowing agents for spray foam; EPS often has favorable embodied-carbon profiles; keep RFB out of direct UV and pick reinforced facers for durability.

Sourcing with Wellco Wholesale: bulk roll widths/lengths, custom slitting, matched tapes/butyl/fasteners, and foam board bundles—ideal for palletized jobs and predictable field installs.

Limitations & Assumptions

-

RFB performance assumes a maintained air gap and sealed seams.

-

Foam performance assumes continuous coverage, sealed edges, and compliance with fire/finish requirements.

-

Manage interior RH (e.g., 40–50% in cold seasons for shops) to avoid condensation.

Decision Guide (TL;DR)

-

Pick RFB for fast installs, radiant control, and condensation management in metal buildings and light commercial retrofits.

-

Pick Foam when you must hit code R-values, reduce thermal bridging, and air-seal.

-

Choose a Hybrid when you need both: RFB as the radiant/vapor layer + continuous foam for predictable R and comfort.

Next step: Share dimensions, climate zone, target R, and install method with Wellco Wholesale to get a quick spec review or sample kit recommendation.

Frequently Asked Questions

1) Can reflective foil bubble wrap insulation replace code-required R-value?

Not by itself. It reduces radiant heat and condensation but doesn’t provide the conductive R/inch needed for most code minimums. Use it alongside foam when codes apply.

2) Do I need an air gap for RFB to work?

Yes. The foil surface must “see” an air space to reflect radiant energy. If you can’t maintain a gap, choose foam.

3) Which foam type should I use in damp or below-grade areas?

EPS or XPS are common below-grade; closed-cell spray foam can also work when detailed properly. Always follow local code and manufacturer guidance.

4) Is foil-faced polyiso a good hybrid partner for RFB?

Often, yes. Polyiso provides continuous R and a low-perm facer; RFB adds radiant control and helps with condensation when placed correctly.

5) What tapes and accessories should I specify?

Use matching foil tapes and compatible butyl/fasteners. Buying matched accessories with your rolls/boards reduces field surprises and helps pass inspections.