Best Bamboo Stakes for Fence: Top Sizes & Uses

Bamboo can be a smart, fast, and good-looking solution for light-duty fence projects—especially when you want privacy, a trellis, or a quick garden partition without the cost and weight of lumber or metal. This guide shows you how to select sizes, plan spacing, install correctly, and maintain multi-season performance.

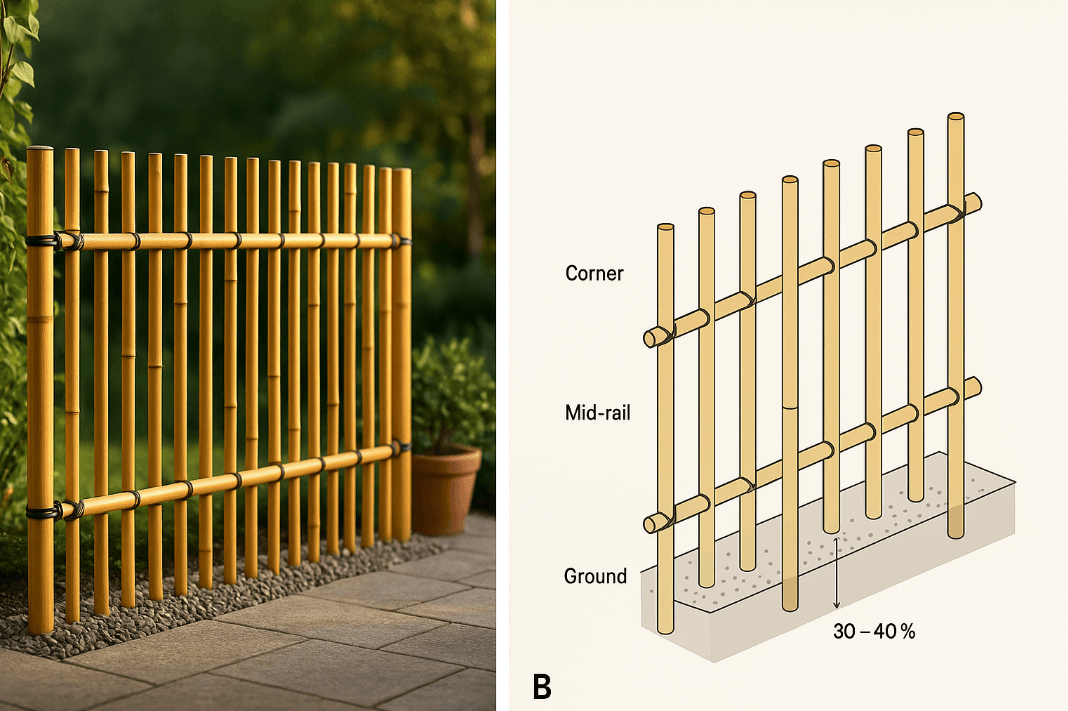

Crew log (first-hand): on a 6-ft condo screen last summer, my panel started to lean during mock-up. I upsized the corner stakes from 12 mm to 16 mm, added a mid-rail at 30", and deflection dropped to under ~2" by the hand-push test. The change added ~8% to material cost but saved a return visit.

About sourcing: Wellco Wholesale is a factory-direct, one-stop wholesaler (garden, farm, hotel, supermarket categories) that can consolidate mixed pallets for trade buyers and still serve small retail orders—useful if you need different diameters and lengths in one shipment.

When Bamboo Stakes Make Sense for a Fence

Common use cases

-

Patio/condo privacy screens

-

Vine-training fence panels along beds or property edges

-

Temporary event barriers and job-site partitions

-

Wind/light filters for seating areas

Pro insight: “When the brief says fast, natural, reversible, bamboo is hard to beat—you can install and remove without scarring the site,” says a senior foreman in Midwest commercial landscaping.

Where they are not ideal (limits)

-

Tall perimeter fences in high-wind zones

-

Code-regulated boundary walls and security enclosures

-

Sites requiring engineered loads or fire ratings

Always check local codes/permits and HOA rules before building.

Top Sizes & How to Choose (Diameter, Length, Spacing)

Height-to-stake rules of thumb

-

Length formula: stake length ≈ clear height × 1.35 (round to nearest 6").

-

Diameter guidance:

-

8–10 mm for light trellis work (≤4 ft)

-

12–14 mm for privacy screens (4–6 ft)

-

16–20 mm for dense cladding or 6–7 ft installs

This keeps hand-push deflection at mid-span near or under ~2"; if it flexes more, upsize diameter or tighten spacing.

-

Spacing & layout patterns

-

On-center spacing: trellis/open screens 12–18"; privacy/dense cladding 6–12".

-

Cross-bracing: add horizontal rails or lashing bands every 24–36" for panels over 5 ft.

Quick selector table

| Desired Height | Exposure | Cladding Density | Suggested Diameter | O.C. Spacing |

|---|---|---|---|---|

| 4 ft | Low | Open (trellis) | 8–10 mm | 12–18" |

| 6 ft | Moderate | Semi-dense slats | 12–14 mm | 8–12" |

| 6–7 ft | Moderate–High | Dense reed/bamboo roll | 16–20 mm | 6–8" |

Labeled diagram (not to scale)

Material & Quality Factors That Drive Longevity

Culm maturity, wall thickness, straightness, grading

Older, thicker-walled culms resist splitting and hold fasteners better. Many commercial species reach useful maturity in ~3–5 years; specify straightness tolerance (e.g., ≤1" bow over 6 ft) for clean sightlines.

Treatments & finishes

-

Boron-based preservation (borax/boric) and/or heat treatment are widely used to deter insects and reduce starch content.

-

Seal for UV and moisture: exterior UV-resistant sealers slow graying and checking; reseal cadence varies by climate (see below).

-

End-cap sealing (wax/resin) reduces water wicking at cut ends.

Quoted guidance: “Boron-based preservatives are widely used to protect bamboo against insect attack and fungal decay in non-structural applications.” — Technical guidance commonly cited by international bamboo organizations

Hardware compatibility

Use galvanized or stainless fasteners and weather-resistant ties/lashing (poly or waxed cord). Avoid mixing dissimilar metals near grade to minimize corrosion.

Micro-glossary

-

Culm: the hollow bamboo stem.

-

Surface checking: small cracks from UV/moisture cycling.

-

Culm maturity: age at which culm has adequate density/strength (often ~3–5 years).

Installation Methods (Step-by-Step)

Ground-driven stakes

-

Layout string lines and mark.

-

Pilot with a bar for rocky soils.

-

Embed 30–40% of stake length (12–24" typical).

-

Backfill with gravel for drainage; concrete only if wind-loaded panels demand it.

Longevity tip: Keep the base 1–2" above soil (via shoes or rails) to reduce soak.

Anchoring to existing structures

Lag rails or compression frames to existing wood/metal posts. Maintain plumb within ±1/8" across a 6-ft panel to avoid racking.

Fastening & panelization

Pre-assemble on sawhorses: lash verticals to horizontals at 12–18" intervals, then mount the panel. Small crews often see 20–30% faster installs with better quality control.

Safety, Compliance & QC (Checklists)

Safety & compliance (pre-build):

-

Call before you dig (811 in the U.S.).

-

Confirm HOA approval and any height/setback/visibility rules.

-

Keep ≤4" gaps where children/pets are a concern.

-

Add diagonal bracing or a mid-rail for dense cladding above 5 ft.

QC on delivery (pro tip):

-

Straightness tolerance: ≤1" bow over 6 ft.

-

Diameter variance: spot-check with calipers; sort by size.

-

Treatment marks: verify heat/borate indicators; culms should be dry to the touch.

-

Reject crushed ends; reseal any fresh cuts before install.

Durability & Maintenance

Climate-zone reseal intervals (typical):

-

Temperate: clean + reseal every 12–18 months

-

Arid/high-UV: 6–12 months

-

Coastal/high humidity: 6–12 months with extra attention to end-grain

Expect natural patina; rinse grime, avoid soil contact, and rotate/replace high-stress stakes at corners.

What voids longevity (top 5):

-

End-grain sitting in wet soil or planters

-

Unsealed cut ends

-

Mixed metals corroding at grade

-

Overspanned spacing with dense cladding

-

No mid-rail/brace on tall panels

Costing & Procurement for Pros (with Light DIY Notes)

BOM mini-calc (example, 24-ft run @ 6" O.C.)

-

Verticals: 24 ft ÷ 0.5 ft = 48 pcs; add 10% overage → 53 pcs

-

Rails/lashing bands: 2–3 rails per 6-ft height run

-

Ties/fasteners: 4–6 per vertical (panelized) or continuous lashing

-

Sealers/caps: size to total linear footage of ends and exposed surface

Cost per 10 linear feet (illustrative; materials only)

| Scenario | Diameter & Spacing | Rails | Ties/Fasteners | Sealer/Caps | Notes |

|---|---|---|---|---|---|

| Trellis / open | 8–10 mm @ 16" O.C. | 1 | Low | Low | Light loads |

| Privacy / semi-dense | 12–14 mm @ 10" O.C. | 2 | Med | Med | Most patios |

| Dense roll screen | 16–20 mm @ 8" O.C. | 2–3 | High | Med–High | Wind-aware |

(Use your local unit costs to price each line; this table standardizes quantities and helps compare options apples-to-apples.)

Reading supplier datasheets (what to look for)

-

Diameter range & tolerance: e.g., 16 mm ±0.5 mm

-

Treatment: heat-treated and/or boron preserved

-

Moisture & finish: dry to touch; pre-sealed or raw

-

Straightness: bow tolerance per length (e.g., ≤1" over 6 ft)

-

Packaging: bundle count, cap options, mixed-size availability

Bulk buying advantages

Consolidate pallets of 12, 16, and 20 mm to match zones (edges lighter, corners heavier). Typical factory lead times run 2–4 weeks for common sizes; add time for specials. Wellco Wholesale can ship mixed SKUs across garden/landscape ranges and also support small retail orders for DIY builds.

Sustainability, Aesthetics & Ethics

Bamboo is rapidly renewable; many species reach useful maturity in ~3–5 years, enabling short rotations compared with softwoods. Thoughtful detailing (bases off soil, caps, sealers) and periodic maintenance extend service life.

Ethical & environmental notes

-

Prefer suppliers documenting responsible harvest and treatment handling.

-

Use low-VOC exterior sealers where possible.

-

Reuse intact pieces as trellis stock at end-of-life; dispose of treated off-cuts per local rules.

Mini Case Study + Standards Anchor

HOA patio privacy screen (anonymized): 18-ft run, 6-ft tall. Spec: 16 mm verticals @ 8" O.C., two horizontals, sealed ends. Install time: 1 day (two-person crew). Year-1 maintenance: clean + reseal; one edge stake replaced after planter wicking.

Standards: when quantified properties are required, reference ISO 22157 test methods for mechanical/physical properties of bamboo; suppliers referencing this provide apples-to-apples data.

Troubleshooting & Alternatives

-

Leaning posts: deeper embed or larger diameter; add a brace rail at 24–36".

-

Cracked culm near fastener: pre-drill or switch to lashing.

-

Panel racking: add diagonal lashing or a mid-rail.

-

Consider alternatives when loads or codes demand them: treated wood posts, steel T-posts, or FRP stakes.

Conclusion

Done right, bamboo delivers a natural look, quick installation, and real value for screens and trellises. Keep the sizing formula handy, mind spacing and bracing, cap and seal the ends, and plan simple seasonal maintenance. Need a mixed-size order or help building a bill of materials? Wellco Wholesale can consolidate diameters/lengths so your crew gets what it needs in one shipment—without overbuying.

Frequently Asked Questions

1) How long will a bamboo stake fence last outdoors?

Exposure and maintenance dominate. With sealed ends and periodic UV-resistant topcoats, panels in temperate climates can serve multiple seasons; re-seal more frequently in full sun or coastal sites.

2) Do I need to treat bamboo before installing it as a fence?

Yes—boron-based preservation (often paired with heat) is a common, low-toxicity approach to deter insects and slow decay. Always seal cut ends and apply an exterior sealer.

3) What diameter should I choose for a 6-ft privacy screen?

Most crews spec 12–14 mm for semi-dense slats and 16–20 mm for dense reed/bamboo rolls, tightening spacing to 6–8" as cladding gets heavier. Use the 1.35× length rule and check deflection during mock-up.

4) How often should I reseal?

Temperate zones: 12–18 months. Arid/high-UV or coastal zones: 6–12 months. Inspect after storms and reseal sooner if checking appears.

5) Are there standards if I need engineering data?

Yes. ISO 22157 defines test methods for bamboo culms. Request supplier data aligned to it so you can compare products consistently.