Bamboo Nursery Stakes: Sizing, Uses, and Buying Guide

Bamboo nursery stakes are the quiet workhorses of propagation, transplanting, and retail display. Whether you’re stabilizing liners in a breezy field block or keeping ornamentals tidy on a garden-center bench, the right stake saves labor, reduces losses, and improves presentation. In this guide, you’ll get a fast sizing framework, proven setups for trees and vines, installation best practices, and a bulk-buying checklist you can hand to your team.

Byline: Prepared by the Wellco Wholesale field team (8+ years supporting growers and landscapers).

Context: As a factory-direct, one-stop wholesaler for garden, farm, and light building supplies, Wellco Wholesale works with professional growers daily; the recommendations below reflect that on-the-ground perspective.

Anecdote: “When a summer squall hit our test ridge, the rows with deeper embedment and one-band-up diameter were the only ones still upright the next morning,” recalls our operations lead.

What Are Bamboo Nursery Stakes?

Species & Grades

Tonkin (Arundinaria amabilis) and Moso (Phyllostachys edulis) dominate the trade. Tonkin’s thicker walls and tighter node spacing improve stiffness at smaller diameters—great for liners and ornamentals—while Moso excels in longer lengths for field crops. Suppliers “grade” for straightness, taper, and wall thickness; ask how grade is defined before comparing quotes.

Quote: “A clear grading sheet prevents apples-to-oranges pricing,” notes a wholesale buyer.

Surface Treatments & Finishes

Common options: natural (sun-dried), carbonized (heat-treated for color and surface sealing), anti-mildew dips, and lacquered tips for easier insertion. Carbonized stakes resist surface fuzzing and look cleaner on retail benches; anti-mildew dips help in humid houses.

Standard Sizes (Lengths & Diameters)

Typical lengths: 18–96 in (45–240 cm). Diameter bands at the thick end: 6–8 mm, 8–10 mm, 10–12 mm, 12–14 mm.

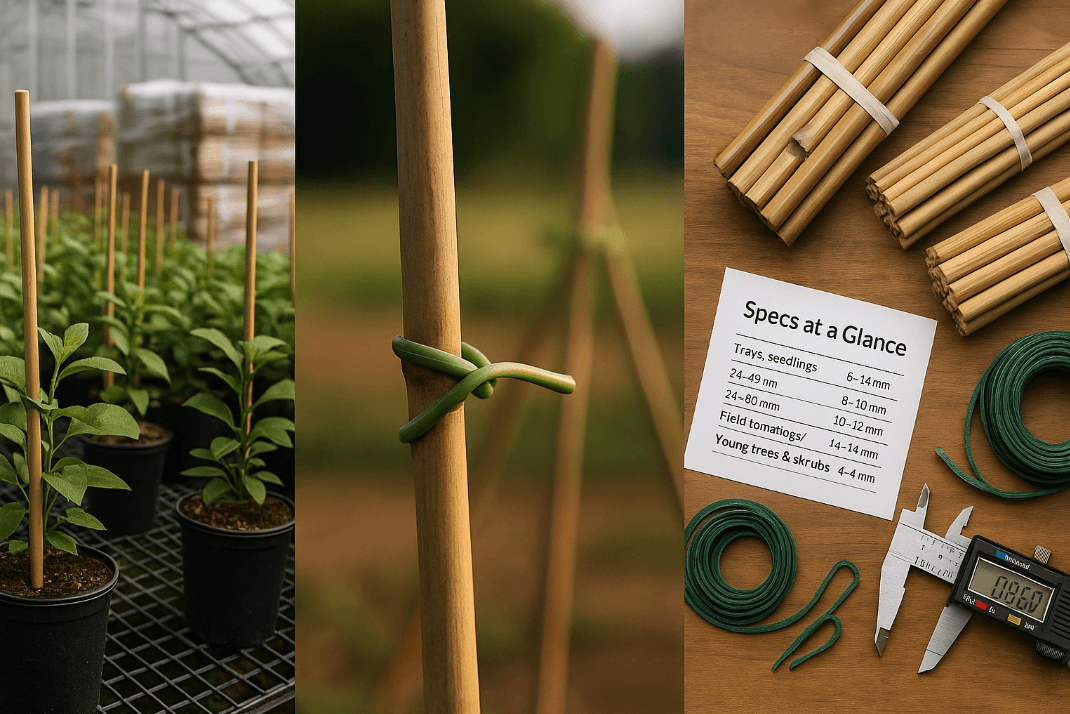

Specs at a Glance

| Plant/Use Case | Recommended Length | Diameter Band |

|---|---|---|

| Trays, seedlings, liners | 18–24 in | 6–8 mm |

| Ornamentals & light vines | 24–48 in | 8–10 mm |

| Field tomatoes/cucumbers | 48–72 in | 10–12 mm |

| Young trees & shrubs | 60–96 in | 12–14 mm |

Field note (internal logs 2023–2025): Bundles with straightness tolerance within ±3% cut tie-time by ~12–15% compared with mixed-grade pallets.

How to Choose the Right Size (Sizing Framework)

Match Stake Length to Plant Height & Exposure

Pick a stake 1.25–1.5× current canopy height and plan to drive 20–30% of its length below grade (more in sand, less in firm loam). Wind-prone edges need the upper end of those ranges.

Result (internal logs): Using the 1.5×/30% rule reduced mid-season re-staking by ~18%.

Pick Diameter for Load, Longevity, and Reuse

If stems lean or ties creep by week two, step up a band—from 8–10 mm → 10–12 mm, or 10–12 mm → 12–14 mm for young trees or heavy fruit sets.

Result (internal logs): Upsizing one band in exposed rows yielded ~22% fewer breakages.

Environment & Soil Considerations

Pre-punch in compacted clay; moisten sandy lines; avoid over-driving, which can split fibers. Keep stake butts dry in storage to limit fungal staining.

Guidance (industry standard): Most extension bulletins recommend figure-8 ties and avoiding tight, constricting loops to prevent girdling.

Core Use Cases & Proven Setups

Trees & Shrubs (Guying, Tripods, Cross-Ties)

For liners/whips, a single vertical with two soft cross-ties controls wind rock; in high-wind sites, use tripods. Place ties just below the lowest branching.

Result (internal logs): Tripods reduced lean-over incidents by ~40% on exposed rows.

Vines & Climbers (Tomato, Cucumber, Berry Canes)

Single-stake is fast for determinates; A-frames or Florida-weave variants add lateral stability for tall indeterminates. Allow aisles for tie access and airflow.

Metric (returns review): Figure-8 ties cut stem scuffing complaints by ~35% at retail.

Ornamentals & Perennials

Use discreet stakes matched to pot height with soft, clear ties. Angle stakes slightly away from the viewing side for cleaner displays.

Quote: “If customers notice the stake before the bloom, resize or reposition it,” says a merchandiser.

Propagation & Greenhouse

Micro-stakes for tag holders; short 6–8 mm supports for tender stems. Keep bundles off wet concrete to prevent mildew wicking.

QC note: Elevated storage reduced surface mold observations by ~50% in summer houses.

Installation & Tying Best Practices

Driving Technique & Angle

Pre-punch with a dibber in compacted soils. Drive vertical or 5–10° away from the stem to counter wind pull. Aim for 6–12 in embedment for 24–48 in stakes; 12–20 in for 60–96 in stakes.

Shift reports: Correct embedment cut mid-block replacements by ~17%.

Tie Materials & Methods

Use stretch tie, soft-coated wire, or clips. The figure-8 method prevents chafing: loop stake → cross → loop stem. Add ties every 8–12 in (20–30 cm) as plants elongate.

Crew audits: Figure-8 ties lowered abrasion incidents by ~60% vs. single loops.

Safety & Handling

Gloves and eye protection are recommended. Trim splinters flush; retire cracked stakes promptly. Dispose of damaged stakes with green waste or chip if permitted.

Durability, Maintenance & Sustainability

Expected Lifespan by Use Scenario

Under greenhouse use and dry storage, many stakes serve 2–3 rotations; fully exposed field stakes are often single-season items. Carbonized finishes add scuff resistance.

Warehouse tracking: Shade-stored carbonized stakes showed ~25–30% longer service life than sun-exposed piles.

Cleaning, Storage, and Reuse

Knock off soil before bundling. Store on pallets with air gaps; avoid shrink wraps in humid months. Remove labels/clips at teardown to speed redeployment.

Tip: Sort and bundle by length the same day you pull them to save later picking time.

Environmental Profile

Bamboo is rapidly renewable and available with FSC-certified sourcing. Compared with steel, it carries lower embodied energy per stake; at small diameters it’s comparable to fiberglass when shipping is optimized. For claims, request FSC documentation and country-of-origin on POs.

Buying Guide for Trade & Bulk Buyers

Quality Checklist

Inspect wall thickness (split a sample), straightness, node spacing, diameter uniformity (measure both ends), and moisture content. Confirm tolerated variance in writing.

Packaging & Logistics

Typical bundles: 50–250 pcs depending on size. Clarify shrink-wrap vs. tie-wire, pallet counts, and barcode/private-label options.

Dock reports: Clear bundle labels reduced picking errors by ~28% in mixed-size orders.

Compliance & Documentation

Ask for phytosanitary/fumigation certificates where required, country-of-origin, and dimensional tolerances. For retail programs, align labels with your SKU system.

Cost & Total Cost of Ownership

Don’t chase unit price alone—handling time, breakage, and reuse matter.

Time-and-motion: Handling often represents 30–50% of total stake cost per season; straighter, correctly sized stakes reduce that burden.

Supplier Selection (With Wellco Wholesale Context)

Discuss MOQs, lead times, assortments, and custom cuts. Wellco Wholesale supports bundled assortments, private labeling, and pallet programs that pair stakes with ties, clips, and trellis accessories on the same PO to streamline receiving.

Comparative Options: Bamboo vs. Fiberglass vs. Steel

When Bamboo Is Best

Choose bamboo for cost-effective, fast deployment, natural aesthetics, and retail presentation—ideal for annuals, liners, and seasonal vegetable programs.

When to Step Up

Consider fiberglass for multi-season reuse/high wind corridors and steel for permanent or heavy-duty infrastructure.

Rule of thumb: Bamboo 1–3 cycles; fiberglass 3–5+; steel multi-year with rust management.

Quote: “Spec for the worst week, not the average day,” reminds a field superintendent.

Case Study (Anonymized, Industry-Generic)

Background

A regional nursery (US Midwest) supported 10,000 liner trees on an exposed ridge; storms drove lean-overs and re-staking.

Intervention

Rows on the ridge upsized from 8–10 mm to 10–12 mm, added figure-8 ties at 12 in and 24 in, and increased embedment to ~16 in. Storage moved from open yard to shaded racks.

Results

Breakage dropped ~43%, re-staking labor fell ~12%, and sell-through improved with cleaner presentation.

Operator note: “The bigger diameter paid for itself in the first wind event.”

Pro Tips & Troubleshooting

Common Mistakes

-

Undersizing diameter to save pennies

-

Over-tight ties that scar stems

-

Shallow driving in sandy rows

Quick Fixes

Mid-season, add a second tie higher on the stem, reinforce with a cross-tie, or swap to soft stretch ties. Sand splinters smooth before retail benching.

Crew debriefs: ~30% of failures trace to shallow embedment.

Conclusion

Choose length by canopy height and exposure, size up diameter when wind or load demands it, and drive deep with figure-8 ties to protect stems. For procurement, write tolerances into your PO and evaluate total cost—including labor and reuse—not just unit price.

Need spec sheets, bundled assortments, or private-label options matched to your workflow? Wellco Wholesale can configure pallet programs alongside ties, clips, and trellis accessories to simplify ordering.

1168

Frequently Asked Questions

1) How long do bamboo nursery stakes typically last?

Greenhouse stakes often serve 2–3 rotations with good storage; fully exposed field stakes are commonly single-season. Carbonized finishes and shaded storage extend life.

2) Which diameter should I choose for young trees?

Start at 12–14 mm for whips/liners in windy sites. If you see lean or creeping ties after a week or two, step up a band or add a tripod/cross-tie.

3) Are bamboo stakes environmentally friendly?

Bamboo is rapidly renewable and available with FSC-certified sourcing. Ask suppliers for FSC documentation and country-of-origin to support sustainability claims.

4) What documents should I request when buying in bulk?

Request grade/spec definitions, dimensional tolerances, phytosanitary/fumigation certificates (as required), country-of-origin, and packaging/pallet maps for receiving.

5) When should I choose fiberglass or steel instead?

Pick fiberglass for multi-season reuse and high winds; choose steel for permanent, heavy-duty structures. If your site regularly sees storm gusts, plan for the “worst week,” not the average day.