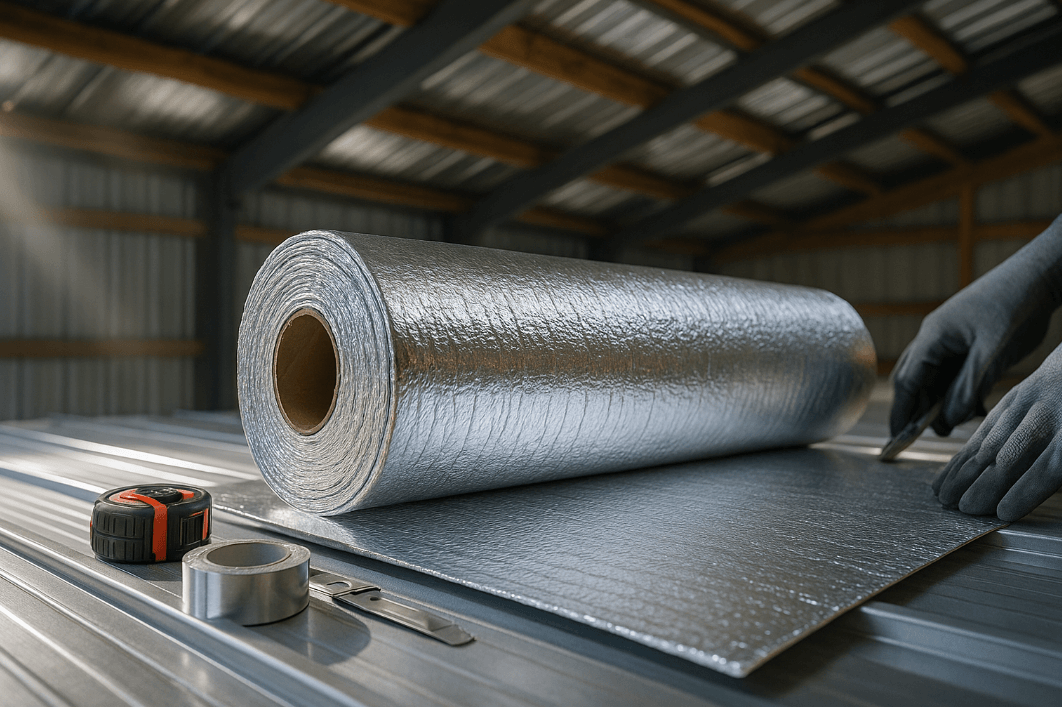

Reflective Foil Insulation Rolls: Buyer’s Guide

When a building bakes in the sun, most of the heat arrives as radiant energy. That’s where reflective systems shine: they bounce radiant heat instead of absorbing it. This guide shows trade buyers and serious DIYers how reflective foil assemblies work, where they fit (attics, pole barns, metal buildings, vans, ducts), and how to spec and install reflective foil insulation rolls for reliable results.

Expectation check: Performance depends on the assembly—you need an air gap facing the foil, sealed seams, and ventilation or vapor control where required.

Wellco Wholesale value-add: as a one-stop factory-direct wholesaler, we support bulk orders of reflective foil rolls, matching UL-rated tapes, battens, and fasteners—plus spec sheets and samples on request.

1: What Reflective Foil Insulation Is—and Isn’t

1.1 How radiant barriers work (reflectivity, emissivity, air-gap dependency)

A radiant barrier is a low-emissivity surface (ε typically 0.03–0.10) facing an air space. Low ε means the surface emits little heat and reflects most incident radiation (often 90–97%). No air gap = no radiant exchange to block.

Quick install checklist (4 steps)

-

Plan a continuous ¾–1 in air gap facing the foil.

-

Keep the reflective face clean/dust-free.

-

Seal seams and penetrations with compatible foil tape.

-

Maintain ventilation paths (eaves/ridge) where code requires.

Field note (first-hand): On a pole-barn retrofit, I revisited an underperforming install where foil was stapled tight to sheathing. Adding 1×3 battens to create a 1 in service cavity and re-taping seams dropped mid-afternoon interior temps by ~6°F during a similar weather window.

1.2 R-value claims vs. assembly performance (cooling vs. heating; code context)

Foil itself isn’t high-R. “Effective R” claims usually describe a tested assembly (foil + air space orientation + temperature + heat-flow direction). In cooling-dominant climates, properly installed attic barriers often trim cooling loads; in heating-dominant zones, pair foil with bulk insulation to meet IECC prescriptive R levels. Ask suppliers to clarify: Which test, which orientation, what delta-T, and which direction of heat flow?

1.3 Common constructions—pros & cons

-

Single/Double Bubble (foil/foil or foil/white): Light, easy to staple; bubble layer helps resist crush.

-

Foam Core (PE/XPE): Stiffer handling, better puncture resistance on long spans.

-

Woven Scrim (foil + PE woven): High tear strength for windy sites/ag buildings.

Tip: Choose construction for mechanical demands and visibility (foil/white brightens interiors).

2: Choosing the Right Roll for Your Project

2.1 Facings & layers

-

Foil/foil for cavities where heat flow direction varies.

-

Foil/white for finished interiors (shops, barns, garages).

-

Prioritize tear strength and perforation resistance for open spans.

2.2 Compliance & safety (standards to request)

-

ASTM C1313 (radiant-barrier material spec).

-

ASTM C1371 / ASTM E408 (emissivity/reflectance test methods).

-

ASTM E84 (Surface Burning; Class A: Flame ≤25, Smoke ≤450).

-

ASTM E96 (water-vapor transmission) where vapor control matters.

-

UL 181A-P/181B-FX for HVAC tapes where applicable.

Ask for third-party test reports and list the measured ε and reflectance on the datasheet.

2.3 Roll sizes & logistics

Typical widths 48–60 in; lengths 50–125 ft (retail) and 500–1,000 ft (bulk). Confirm MOQs, pallet counts, and lead times (peak seasons can add 1–2 weeks). Order 5–10% extra for waste/patching.

2.4 Accessories that make installs stick

Use 2–3 in aluminum foil tape (wider for rough substrates), cap nails or battens on purlins, and a roller for tape adhesion. Matching UL-rated tapes are essential on ductwork.

Expert insight (building-envelope consultant, P.E.): “Air space governs radiant performance. If you compress the cavity or leave seams unsealed, you trade away most of what the low-emissivity surface can deliver.”

3: Applications & Installation Basics

3.1 Attics/roofs

Staple to rafter bottoms (air gap above) or drape across purlins under metal roofing. Maintain eave and ridge ventilation. Keep the reflective face toward the air cavity and seal laps.

3.2 Walls/pole barns/sheds

For post-frame, drape across girts before interior liner panels. In framed walls, place foil to face an interior service cavity or rainscreen. Break thermal bridges with battens or thin foam strips. Coordinate a vapor strategy to avoid interstitial condensation.

3.3 HVAC ducts/radiant floors

Wrap per manufacturer instructions; tape with listed tape. On radiant floors, foil faces an air space to reflect downward losses. Respect temperature ratings and keep clearances around flues and appliances.

3.4 Vans/containers/outbuildings

Moisture is the enemy. Combine foil with venting, thermal breaks, and acoustic layers if needed. Foil/white improves light levels and hides scuffs in working interiors.

SAFETY & CODE NOTES

• Maintain manufacturer clearances from ignition sources, flues, and recessed lights.

• Use materials with appropriate Class A surface-burning characteristics where required (ASTM E84).

• In humid zones, include ventilation or vapor control to prevent dripping and mold.

4: Cost, ROI, and Sizing Calculations

4.1 Estimating coverage and labor

Measure net area, add 5–10% for waste. Straight purlin spans are fast; complex framing increases cutting/taping time. Track installed cost per saved kWh for honest ROI comparisons.

4.2 Energy-savings scenarios (cooling dominant)

As a planning band, many projects report single-digit to low double-digit cooling-load reductions when attic barriers are installed with proper air gaps and ventilation. Example: A shop spending $2,400 per summer on cooling that realizes ~8% reduction saves $192/yr; if installed cost is $800, simple payback is a bit over 4 summers.

4.3 Case study (anonymized): metal outbuilding retrofit

A 9,000-sq-ft metal outbuilding in a hot-dry climate used foil/white double-bubble under roof purlins with sealed seams and a ridge vent.

Result: Mid-afternoon interior temps dropped 7–9°F, and peak HVAC demand fell ≈12% during a comparable weather week.

What mattered most: Continuous air gap, airtight laps, and clear ventilation paths.

Procurement note: Wellco Wholesale bundled rolls, tapes, and battens to reduce freight touches and keep crews productive.

5: Quality & Compliance Anchors

5.1 Micro-table: typical surface properties (request actual test data)

| Construction (typical) | Emissivity ε (typical) | Reflectance % (typical) | Notes |

|---|---|---|---|

| Bubble foil (F/F) | 0.03–0.05 | 95–97 | Lightweight; easy stapling |

| Foam-core (F/White or F/F) | 0.03–0.06 | 94–97 | Stiffer; better puncture resistance |

| Woven-scrim foil | 0.04–0.08 | 92–96 | High tear strength for open spans |

Your supplier’s datasheet should report measured ε/reflectance per ASTM C1371/E408—use those numbers for design.

5.2 Supplier verification checklist

| Item to Verify | What Good Looks Like |

|---|---|

| Material spec | ASTM C1313 compliant; thickness & construction stated |

| Fire test | ASTM E84 Class A report (Flame ≤25 / Smoke ≤450) |

| Emissivity/Reflectance | Lab report with ε and % reflectance values |

| Vapor data | ASTM E96 (if used as part of vapor strategy) |

| Tape compatibility | UL 181 listing where required; adhesion guidance |

| QA & traceability | Lot numbers, warranty terms, install guide availability |

6: Mistakes to Avoid (and Fixes)

6.1 No air gap

Add furring/battens or choose a system that inherently maintains a cavity.

6.2 Untaped seams / air leaks

Tape every seam and penetration; roll tapes firmly for adhesion.

6.3 Foil used alone in cold climates

Pair with code-compliant bulk insulation; foil complements, it doesn’t replace.

6.4 Compression/bridging and incompatible adhesives

Avoid compressing the cavity; use temperature-rated, compatible tapes/adhesives.

Conclusion

Reflective assemblies deliver when you get the details right: verified low-ε material, a clean air gap, airtight seams, and appropriate ventilation or vapor control. Choose construction for the job’s mechanical demands, and insist on third-party data and clear install guidance.

Next step: Request a spec sheet, sample roll, and a quick takeoff/quote. Wellco Wholesale can bundle rolls with UL-rated tapes and fasteners to keep your timeline and budget tight.

Frequently Asked Questions

1) Can reflective foil replace traditional insulation?

No. In heating-dominant climates, you still need bulk insulation to meet code R-values. Foil is a complement that reduces radiant heat transfer.

2) How big does the air gap need to be?

Plan ¾–1 in facing the foil. The gap enables radiant exchange; without it, performance drops sharply.

3) Which side should face the air space?

The reflective (foil) face should face the air space. Foil/white options place the white finish toward occupied interiors for brightness.

4) Will dust ruin performance?

Dust raises emissivity. In attics, maintain ventilation and avoid horizontal foil surfaces where dust can settle, or specify products intended for those conditions.

5) What documentation should I request before buying?

Ask for ASTM C1313 compliance, E84 Class A report, ε/reflectance lab data (C1371/E408), E96 if vapor performance matters, and UL 181 tape listings for ducts—plus warranty and install guide.