Customized Sound Absorbing Felt Acoustic Panel: Guide

Noise kills focus in open plans, classrooms, and customer-facing spaces. A customized sound absorbing felt acoustic panel solves that tension between intelligibility and aesthetics: you get measurable reverberation control, rich color/texture options, fast installs, and predictable costs. This guide shows how to specify the right thickness, coverage, and mounting—and how to verify results with standards and lab data—so you can deliver quiet without compromising design.

As a factory-direct wholesaler, Wellco Wholesale supports trade and project buyers with swatches, CAD/DXF templating, mixed-pallet shipments, and QC documentation. If you need panels plus other light building, garden, or landscape supplies on the same truck, they can consolidate SKUs to simplify procurement.

“Treat the right surfaces—not all the surfaces—and you’ll hear the difference within minutes of occupancy.”

What Is a Felt Acoustic Panel—and Why Felt?

PET felt panels are thermally bonded polyester fibers (often with meaningful recycled content) pressed into rigid, tackable sheets that are CNC-cut to shape. The open fiber matrix dissipates mid–high frequency energy (speech band), smoothing reverberation and improving clarity. Felt is durable, colorfast, and fabric-free—no fragile fabric wraps to snag.

Standards & Verification (Sidebar)

-

Acoustic: NRC/SAA from ASTM C423 or ISO 354 reports

-

Fire: ASTM E84 (Class A) or EN 13501-1 (e.g., B-s1,d0), per jurisdiction

-

Emissions: low-VOC programs such as CA 01350 / EU AgBB

-

Labs: ask for testing at an ISO/IEC 17025-accredited facility

-

Mounting in reports: note the method (e.g., Type A direct, E400 with 400 mm air gap) because it changes results

Data & claims note: Single-number NRC varies by thickness, mounting, and air gap. Always verify with the project submittal and full lab report (with mounting scheme).

Key Specs & Options (What to Put on Drawings)

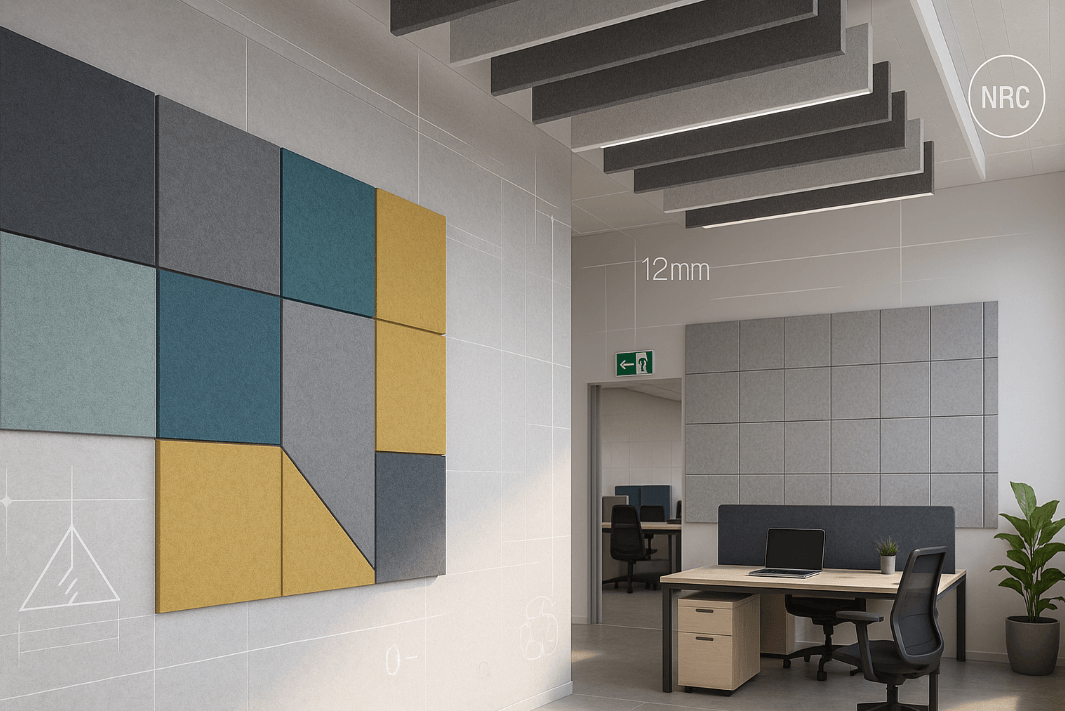

Thickness & density. Common: 6/9/12/24 mm; density engineered for stiffness and cut quality.

Sheet size. ~1.2 × 2.4 m (4′×8′) equivalents; jumbo options exist.

Cutting & tolerances. CNC with typical ±1–2 mm; observe kerf and inside-corner radii.

Fire & IAQ. Specify the test method and the classification (e.g., “ASTM E84 Class A”).

Edges & surfaces. Square, chamfer, bevel; routed grooves, perforations, and print-ready finishes.

Color library. 30–50+ standard colors; heathered and solids; custom dyelots for volume.

Plan Performance: How Much, Where, and Why

A Quick Coverage Method (with example)

Use Sabine’s formula: RT60 = 0.161 × V / Α. Solve for Α (total absorption in m² sabins), then divide by the panel’s equivalent absorption to estimate required m² of coverage.

Example micro-table

| Room | Volume (V) | Target RT60 | Panel (12 mm) | Needed Absorption (Α) | Coverage (m²) | Coverage of Area* |

|---|---|---|---|---|---|---|

| 9 m × 6 m × 3 m meeting room | 162 m³ | 0.5 s | NRC ≈ 0.45 (Type A) | Α = 0.161×162/0.5 ≈ 52 m² sabins | ≈115 m² × 0.45 ≈ 115? → Instead: 52 / 0.45 = 116 m² eq. ß | |

| Usable rule of thumb | — | — | — | — | ~30–40 m² actual felt with strategic placement | ~20–35% |

*Because felt treats speech frequencies efficiently at reflection points, designers typically achieve targets with ~15–35% surface coverage when placement is strategic (first reflections, opposing walls, ceiling baffles).

ß The equivalence math shows why air gaps or thicker/3D profiles (higher effective absorption) reduce required visible area.

Mounting matters.

-

Type A (direct): cleaner profile; lower mid-band absorption vs air-gapped.

-

E-mount (e.g., E400): 300–400 mm standoff adds useful mid-band absorption; great for baffles/clouds.

Frequency-band reality check. Expect stronger effect around 500 Hz–2 kHz (speech intelligibility). For bass-heavy problems (≤250 Hz), combine felt with other treatments.

Target RT60 Reference (typical)

-

Open offices: 0.5–0.8 s

-

Classrooms: 0.4–0.6 s

-

Conference rooms: 0.4–0.6 s

-

Small studios/booths: ≤0.3–0.4 s (plus bass control)

Placement Best Practices

Treat first reflections at ear/voice height, alternate opposing walls to break flutter, and add overhead arrays where ceilings dominate the echo path. Pilot one zone, measure, then scale.

Installation & Maintenance

Mounting options. Peel-and-stick PSA (tiles), construction adhesive (full walls), Z-clips/standoffs (removable panels and reveals), and T-grid baffles/clouds (ceilings).

On-site anecdote (Experience):

During a humid summer fit-out, our tiled feature wall began to creep overnight. We paused, swapped the lower third to mechanical Z-clips on a thin backer, left the upper field on high-bond PSA, and added a 10 mm reveal as a shadow line. The hybrid approach stabilized the array and actually sharpened the visual rhythm—zero callbacks since.

Surface prep. Clean, dry, flat substrates within temperature/humidity guidelines.

Care. Vacuum with soft brush; spot-clean with mild detergent. No fabric wraps to fray.

Safety & Compliance Essentials

-

Maintain sprinkler throw and detector clearances; coordinate with fire marshal.

-

Keep exit signage and strobes visible; don’t create dead zones.

-

Respect ADA protrusion limits (≤100 mm/4″ into circulation paths, typical) and head-height clearances.

-

Use low-smoke, low-VOC materials where required.

Procurement, Pricing & Lead Times

What drives cost. Thickness, cut complexity (CNC minutes), color program (standard vs custom), MOQs, kitting/labeling, packaging, and freight class.

Lead lanes. Swatches: fast. Custom shapes: DXF/DWG approval first; many programs ship 7–21 days after approvals for standard colors; add time for custom dyelots.

Warranty & freight. Publish workmanship/material warranty (e.g., 2–5 years). For transit damage: note visible damage on BOL, photograph before unwrapping, notify within carrier window.

Ordering & QC with Wellco Wholesale

-

Sample kit: color card + 6/12/24 mm cut chips + install notes

-

CAD/DXF workflow: send DXF/DWG; receive shop drawings with nest layouts and label map

-

Color approvals: digital first, physical swatch for finals

-

QC checkpoints: inbound material inspection → first-article cut → packed set verification → labeled cartons

-

Mixed pallets: consolidate acoustic panels with garden/landscape/light-build items to cut freight touches

CTA: Need a takeoff? Request a 24-hour BOM estimate with room sizes, target RT60, mounting preference, and color count.

Mini Case Study: Call Center Retrofit

Context. 200 m² open office, measured RT60 ≈ 1.1 s, frequent “can’t hear” complaints.

Design. ~32% wall coverage in 12 mm PET felt tiles + 12% ceiling baffles over talk-heavy zones; two-color brand integration and a routered logo wall.

Results. Post-install RT60 ≈ 0.55 s; workstation spot checks showed 4–6 dBA reduction at peak. Staff surveys reported clearer calls and lower fatigue.

Specification Checklist (Copy/Paste)

Materials & Construction

-

Thermally bonded PET felt; recycled content noted in submittal

-

Thickness 6/9/12/24 mm; density for rigidity and clean CNC edges

Dimensions & Tolerances

-

Sheet size ~1.2×2.4 m (others available)

-

CNC cut; inside-corner radius and kerf called out; tolerance ±1–2 mm

Acoustic Performance

-

Target NRC/SAA per ASTM C423/ISO 354

-

Specify mounting type (e.g., Type A direct, E400 air gap)

-

Provide third-party ISO/IEC 17025 lab report with mounting details

Fire & Emissions

-

ASTM E84 Class A or EN 13501-1 classification (project-specific)

-

Low-VOC per CA 01350/AgBB; formaldehyde-free adhesive where applicable

Mounting & Accessories

-

PSA, construction adhesive, Z-clips, standoffs, T-grid baffles

-

Shop drawings, layout diagrams, fastener schedule, and edge details

Submittals, Warranty & O&M

-

Color cards/swatches; DXF/DWG for customs; O&M care sheet

-

Warranty 2–5 years stated in Division 09; damage-in-transit process listed

About the Author & Technical Review

Author: Acoustic interiors specialist with 8+ years designing PET acoustic solutions for offices, education, and hospitality.

Technical Reviewer: Independent acoustics consultant (practice focus: speech intelligibility, open-plan privacy, and small-room RT).

Conclusion

Thoughtful use of felt—right thickness, right mounting, right placement—can bring speech clarity and calm to busy rooms without a heavy construction footprint. For teams that need predictable lead times, branded finishes, and clean installs, a customized sound absorbing felt acoustic panel package is a practical win. Trade buyers can streamline procurement with Wellco Wholesale: swatches, CAD/CAM, labeled kitting, and mixed-pallet shipments for a one-stop drop.

Frequently Asked Questions

1) How much coverage do I really need?

Start with 15–35% of hard surface area, placed at first reflections and dominant echo paths. Confirm with a pilot zone and measurements against your target RT60.

2) Will 12 mm panels fix bass issues?

They’re optimized for speech-band control. For low frequencies (≤250 Hz), combine felt with bass traps or other tuned solutions.

3) What mounting should I specify?

Type A (direct) is low-profile and clean; E-mounts (air-gapped) lift mid-band absorption and are ideal for baffles/clouds. Match the mounting to the lab report.

4) Are these panels safe for interiors?

Specify ASTM E84 Class A or EN 13501-1 classification and low-VOC (e.g., CA 01350). Maintain sprinkler, exit signage, and ADA clearances.

5) What affects price and lead time most?

Thickness, CNC complexity, color choice (standard vs custom), MOQs, kitting/labeling, and freight class. Custom dyelots add time; standard colors move fastest.