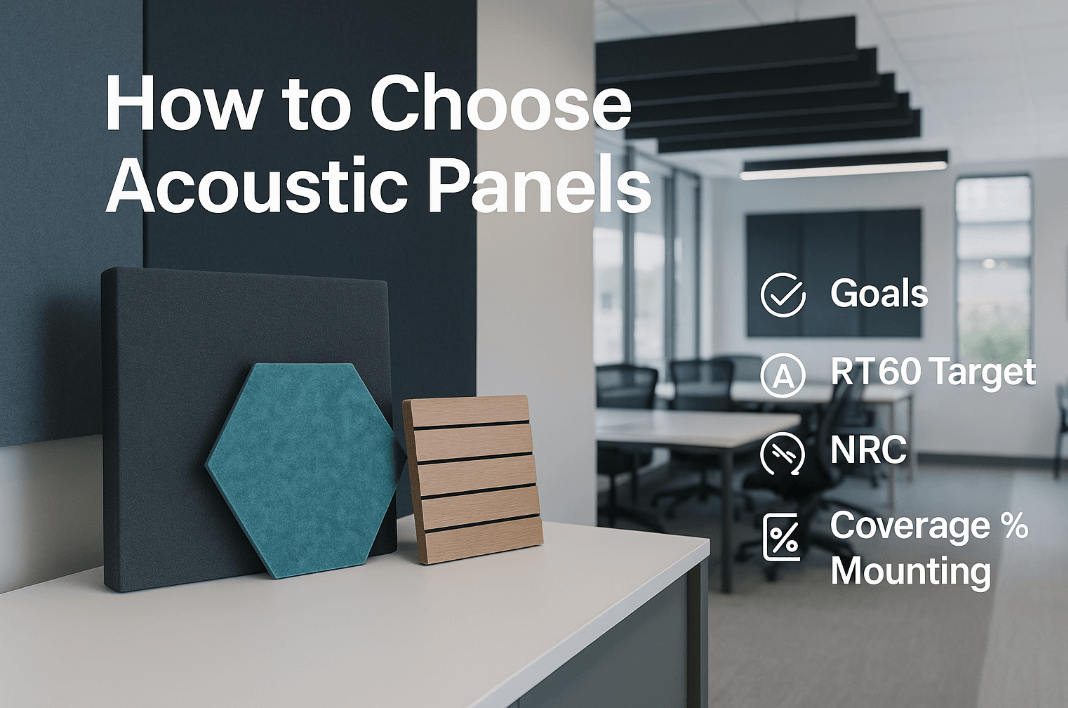

Acoustic panels sound absorbing panels - how to choose?

Noise steals time, focus, and customer satisfaction. In offices it lowers productivity; in restaurants it shortens visits; in classrooms it hides speech cues. Acoustic panels (sound absorbing panels) turn echo energy into heat at the fiber level, reducing reverberation so voices sound closer and clearer. This guide explains how they work, how to choose by space type, how many you actually need, and smarter ways to install and buy. For trade buyers, Wellco Wholesale supports factory-direct quotes, sample kits, and volume pricing without a hard sell.

Limits & Expectations

Absorbers reduce in-room echo; they do not “soundproof.” If you hear neighbors through a wall, you need mass + isolation assemblies (STC), not just absorptive panels (NRC). Panels shine when the goal is clarity and comfort inside the room.

How Acoustic Panels Work & What to Look For

Absorption vs. Blocking (NRC vs. STC)

-

NRC (Noise Reduction Coefficient) describes how well a product absorbs sound in a room.

-

STC (Sound Transmission Class) describes how well a wall/door assembly blocks sound between rooms.

Typical fabric-wrapped fiberglass or PET felt wall panels rate NRC 0.70–1.00 when sized and installed correctly. Use NRC for in-room echo control; use STC when planning partitions and doors.

Core Materials & Constructions

-

Fabric-wrapped fiberglass/mineral wool — top broadband absorption per inch; 25–50 mm thickness is common for speech clarity.

-

PET felt (recycled polyester) — durable, tack-friendly, excellent for schools and agile offices; often includes post-consumer content.

-

Wood-slat + felt backing — design-forward; good mid/high absorption, limited bass unless the felt/backing is thicker.

-

Perforated wood/metal w/ backing — tunable via hole ratio and cavity depth; great for multipurpose rooms.

-

Acoustic foam — useful near sources; check fire ratings and aging.

Health, Safety & Compliance

Ask for: ASTM E84 Class A (surface burning), low-VOC declarations, and moisture/mold resistance for kitchens or natatoriums. Many PET felts are formaldehyde-free and contain recycled content. Datasheets and test reports should be available on request.

Targets by Room Type (Quick Planner)

| Room Type | RT60 Target | Typical Thickness | Coverage % (walls+ceiling) | Ceiling Share |

|---|---|---|---|---|

| Open office / BPO | ≤ 0.7–0.9 s | 25–50 mm | 15–25% | 40–60% |

| Classroom / Training | ≤ 0.6–0.8 s | 25–50 mm | 15–30% | 30–50% |

| Conference room | ≤ 0.5–0.6 s | 25–50 mm | 20–30% | 30–50% |

| Restaurant | ≤ 0.8–1.0 s | 25–50 mm | 20–35% | 50–70% |

| Fitness/Gym | ≤ 1.0–1.2 s | 25–50 mm | 25–35% | 60–80% |

| Home studio | ≤ 0.3–0.5 s | 50 mm+ + traps | 30–40% (+traps) | 20–40% |

Notes: RT60 is the time for sound to decay 60 dB. Ceiling treatments (clouds/baffles) are highly effective because they “see” more sound paths.

How to Choose for Your Space & Goals

Open Offices & Call Centers

Goal: reduce cross-talk and raise speech intelligibility. Pair ceiling baffles/clouds with wall panels behind talkers. Start at 15–25% treated area, with at least half on the ceiling. Desk dividers add local absorption without changing architecture.

Classrooms, Training & Conference Rooms

Aim for RT60 ≤ 0.6–0.8 s depending on size. Place 25–50 mm panels at ear height on sidewalls, plus clouds above seating. Use tackable PET or fabric-wrapped boards for dual-purpose writing/pinning.

Home Studios & Podcasting (First-Hand Vignette)

When I treated a small bedroom studio, I started with the mirror trick on sidewalls and ceiling to locate first reflections, then added 50 mm corner bass traps. Early reflections dropped by ~10 dB at the mic; vocal takes needed less EQ and sounded consistent across sessions. Leave some diffusion/bookshelves so the room doesn’t go dull.

Restaurants, Retail & Gyms

Favor impact-resistant PET or perforated slat/metal systems. Prioritize ceilings to keep wall real estate free for art and signage. For busy kitchens or natatoriums, confirm moisture resistance and cleanability.

Sizing, Quantity & Layout

Quick Room Estimate (RT60 Made Simple)

Use Sabine’s formula:

-

SI units: RT60 ≈ 0.161 × V / A, where V is room volume (m³) and A is total absorption (m² sabins).

-

Imperial: RT60 ≈ 0.049 × V(ft³) / A(sabins).

To halve RT60, you must roughly double the room’s total absorption.

Small Office Example: 9 m × 6 m × 3 m → V = 162 m³.

If current RT60 ≈ 1.2 s, then A₀ ≈ 0.161×162/1.2 ≈ 21.7 sabins.

Target RT60 = 0.6 s → Aₜ ≈ 0.161×162/0.6 ≈ 43.5 sabins.

Add ΔA ≈ 21.8 sabins. With NRC 0.80 panels, each m² contributes ~0.8 sabin → need about 27 m² of panels (e.g., 18 m² ceiling clouds + 9 m² wall panels).

Worked Example: 120-Seat Restaurant

Assume dining room 20 m × 15 m × 3.5 m → V = 1050 m³.

Measured RT60 ≈ 1.8 s ⇒ A₀ ≈ 0.161×1050/1.8 ≈ 93.9 sabins.

Target RT60 = 0.9 s ⇒ Aₜ ≈ 187.8 sabins.

Needed ΔA ≈ 93.9 sabins.

A practical mix: 40 m² of double-sided ceiling baffles (αₑq≈1.6 → 64 sabins) + 37 m² of wall panels (α≈0.8 → 29.6 sabins) ≈ 93.6 sabins total—meeting the target while leaving walls mostly open.

Placement Rules of Thumb

-

Treat first reflections (sidewalls/ceiling); keep placement symmetrical around listeners.

-

Don’t cluster everything on one wall; distribute to avoid “dead-end/live-end” imbalances (unless mixing suites).

-

Ceiling “sees” the most sound paths—treat the sea, not just the shores.

Installation & Maintenance

Mounting Methods

-

Adhesive/impaling clips for fast, low-profile wall installs.

-

Z-clips/French cleats for removability and heavier panels; check hardware ratings.

-

Stand-offs for shadow-gap aesthetics; cable kits for clouds and canopies.

Code & Safety Considerations

Maintain sprinkler and luminaire clearances, preserve egress widths, and use seismic restraints where required. In corridors and gyms, choose impact-rated faces or higher-density cores.

Care, Cleaning & Longevity

Vacuum fabric-wrapped panels periodically; spot-clean with mild solutions. PET/felt resists scuffs and accepts push pins. Commercial warranties are commonly 5–10 years; well-mounted panels often last far longer in low-abuse areas. Set a quarterly inspection for loosening hardware or soiling in high-traffic spaces.

Budgeting, Customization & Procurement (with Trade Tips)

What Drives Cost

Size, thickness, core, fabric grade, edge details, hardware, and freight. Printed graphics and wood-slat veneers add premiums. On large jobs, freight can be a notable share—optimize carton sizes and delivery windows.

Customization Options

Brand-matched colors, custom prints, CNC-cut shapes, slat spacing/profiles, and edge details (square/bevel/radius). Ask for mockups to align design, readability, and acoustic coverage.

Buying in Bulk & Lead Times

Stocked SKUs often ship in 2–4 weeks; custom colors or slat programs can run 4–8+ weeks depending on season. For phased projects, stage deliveries floor-by-floor. Wellco Wholesale can assemble sample kits (fabric swatches, PET felt, fastener options), advise on MOQ for customs, share test datasheets, and consolidate freight across product categories to simplify receiving.

Mini Case Study (Anonymized)

Problem: A 6,000-sq-ft open office with exposed concrete and glass measured RT60 ≈ 1.4 s and frequent cross-talk complaints.

Approach: Installed 38 mm PET ceiling baffles covering 22% of ceiling area, plus 50 mm wall panels behind desking and in huddle rooms (added absorption ≈ 420 sabins).

Result: Post-treatment RT60 ≈ 0.6 s; average background speech at workstations dropped 6–8 dB.

Quote — Facilities Manager, 200-seat BPO floor: “Calls stopped stepping on each other, and we spent less time repeating ourselves in meetings.”

Methodology note: RT60 measured via interrupted noise method at multiple mic positions; background levels averaged across occupied work hours.

Quick Comparison & Buyer Checklist

10-Point Checklist

-

Clear goal (privacy, clarity, loudness)

-

Target RT60 set by room type

-

NRC spec and panel thickness chosen

-

Coverage % and ceiling share determined

-

First-reflection points mapped

-

Fire rating and VOC requirements verified

-

Mounting method & substrate confirmed

-

Impact rating where needed

-

Warranty, maintenance, and lead time aligned

-

Freight plan & site access organized

Conclusion

Choosing the right acoustic panels (sound absorbing panels) is systematic: define goals, pick the right core and thickness, size coverage with a quick RT60 calc, and install with code-aware hardware. If you’d like a fast sizing sketch or a hands-on sample kit for stakeholders, Wellco Wholesale can support trade and project buyers with quotes, mockups, test reports, and consolidated logistics.

Frequently Asked Questions

1) How many panels do I need for a typical conference room?

Use the quick calc: estimate room volume, pick a target RT60 (≈0.5–0.6 s), and add enough absorption to reach it. As a shortcut, start around 20–30% treated area with at least one-third on the ceiling.

2) Do thicker panels always work better?

Up to a point. 50 mm panels absorb lower mid-frequencies better than 25 mm, which helps speech clarity in larger rooms. Very thick panels won’t fix neighbor noise—that’s an STC/isolation issue.

3) Are PET felt panels safe and durable in schools?

Yes, when they meet Class A fire ratings and low-VOC criteria. PET is tackable and impact-resistant, making it popular for classrooms and corridors.

4) Can I DIY the install?

Many wall installs are DIY-friendly (adhesive, impaling clips, cleats). Suspended clouds and large baffles may require professional hardware, seismic restraints, or trade permits—check local codes.

5) What documentation should I request before ordering?

Ask for NRC test reports, ASTM E84 (or local equivalent), VOC declarations, warranty terms, and mounting/hardware load ratings. For customs, confirm color samples and edge details.