Reflective Foil Roof Insulation vs Fiberglass: Which Wins?

When should reflective foil roof insulation (radiant barrier) beat fiberglass (thermal blanket)—and when is the hybrid approach the real champion? Short answer: radiant barriers slash radiant heat gain in sun-soaked roofs (especially metal), while fiberglass delivers the R-value that codes require in every climate. Most trade buyers get the best comfort and ROI by combining them. For streamlined procurement, Wellco Wholesale can palletize foil rolls, compatible tapes, ridge/soffit vents, and fiberglass formats in one mixed-SKU shipment for farms, landscapers, and light commercial projects.

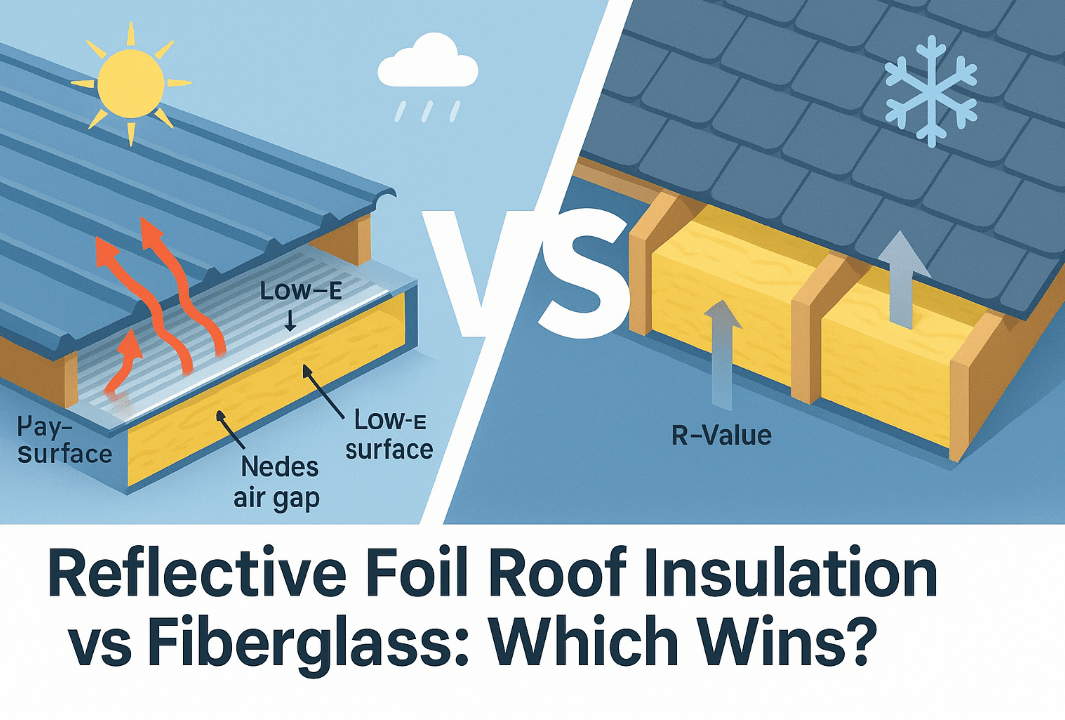

How Each Material Works (and What It Measures)

Radiant Barriers 101: Emissivity, Air Gaps, and Reflectivity

Reflective foil works by presenting a low-emittance surface to an adjacent air space, reflecting radiant energy before it warms the structure. Performance drops if dust coats the shiny face, so keep it downward-facing or otherwise protected. The key: no air gap = no meaningful radiant benefit.

Fiberglass 101: R-Value, Thickness, and Fit

Fiberglass resists conduction. Thickness drives R-value; compression, gaps, and wind-washing erode it. Good installs keep full depth, add baffles at eaves, and pair with air-sealing.

Apples vs Oranges: R-Value ≠ Radiant Performance

R-value (ASTM C518) measures conductive resistance. Radiant barriers are characterized by emittance/reflectance (e.g., ASTM C1371). Don’t compare a foil’s “R” to fiberglass—design the assembly for your climate, roof type, and moisture risks.

Where Each Wins: Climate, Roof Type, and Use Case

Hot/Dry & Hot/Humid (Sunbelt, metal roofs, low-slope)

Radiant barriers shine at reducing roof-deck/attic heat gain. They pair well under metal panels on purlins or over battens that create a continuous air space. Maintain attic ventilation; seal seams; keep the low-e face aimed at the air gap.

Cold & Mixed Climates (heating-led)

First, meet prescriptive attic R-values with fiberglass. Add a radiant barrier where summer solar gain is meaningful (cathedral ceilings, dark shingles, ducts in attics) to trim peak loads.

New Build vs Retrofit

-

New build: Easiest to add a continuous foil layer with a defined air space and thermal breaks.

-

Retrofit: Staple foil to rafters (not laid on insulation), then top up fiberglass on the attic floor—without blocking ventilation paths.

Performance in Numbers (What to Expect)

-

In monitored hot-climate projects, radiant barriers commonly deliver ~5–10% cooling energy savings and noticeable peak load reductions when installed with a real air gap.

-

Hybrid assemblies (foil + correct R) improve summer comfort by reducing mean radiant temperature while the fiberglass holds conductive losses year-round.

Moisture, Condensation & Vapor Control (Quick Guide)

-

Vapor classes: Class I ≤0.1 perm (e.g., many foil facers), Class II 0.1–1.0 perms, Class III 1–10 perms.

-

In cold climates, put the vapor retarder on the warm-in-winter side; in mixed/hot-humid, prioritize drying potential and ventilation.

-

Foil can double as a vapor retarder—verify perm ratings and place carefully to avoid trapping moisture.

A Quick Field Note (Experience)

On a Zone-2 metal-roof retrofit, we battened the deck with ¾″ strips to preserve an air gap and stapled low-e foil shiny-side to the gap. Data loggers showed an 8–10°F lower underside deck temperature on clear afternoons versus adjacent non-retrofit bays. Crew feedback: cooler work area, easier to keep duct runs below 120°F.

Simple Air-Gap Diagram

Installation Methods and Common Mistakes

Radiant Barrier: Do This

-

Preserve a continuous air space (3/4″–1½″ is typical).

-

Face the low-e surface toward the air gap; tape seams; keep it as dust-sheltered as practical.

-

Keep clearances from chimneys, flues, and recessed luminaires; never contact live conductors.

Fiberglass: Do This

-

Install full depth without compression; friction-fit batts snug to framing.

-

Add baffles at eaves; block wind-washing; pair with attic air sealing.

-

Select the facer (kraft/FSK/unfaced) to match your vapor strategy.

Compliance & Safety (Pin This on Your Submittals)

-

Emittance/Reflectance: ASTM C1371 (or E408).

-

R-value (fiberglass): ASTM C518.

-

Surface Burning: ASTM E84 / UL 723 classification for exposed facers.

-

Maintain thermal clearances around flues/lights per local code and manufacturer instructions.

Cost, ROI, and Ownership (Trade Buyer View)

Prices vary by region, buying tier, and fuel rates. Ranges below are typical as of September 2025.

-

Radiant barrier materials: $0.15–$0.90/ft² (one- to two-sided foil, scrim/bubble/foam-core).

-

Radiant barrier installed (typ.): $0.50–$1.50/ft² when added during reroof or attic retrofit.

-

Fiberglass batts (materials): $0.80–$1.80/ft² depending on R and facer.

-

Blown-in fiberglass (installed): $0.50–$1.30/ft² for top-ups to common attic targets.

ROI patterns: Fastest in cooling-dominated metal buildings and attics with ducts (radiant barrier trims peak/latent loads). In cold zones, ROI is driven by reaching IECC-recommended R first; foil adds summer comfort and may modestly reduce shoulder-season gains.

IECC Climate Zones → Typical Attic R-Value Targets

(Verify local amendments; 2021/2024 IECC guidance commonly aligns as follows):

| Zone | Typical Target |

|---|---|

| 1 | R-30 |

| 2 | R-38 |

| 3 | R-38 |

| 4 | R-49 |

| 5 | R-49 |

| 6 | R-60 |

| 7–8 | R-60+ |

Specifying & Buying at Scale (Procurement Checklist)

Foil selection: single/double bubble, woven-scrim, or foam-core; emittance ≤0.05 typical; confirm perm class.

Fiberglass selection: batts/rolls/blown-in; select facer (kraft/FSK/unfaced) and thickness to hit the R for your zone.

Documents to request: data sheets (emittance/R), E84 classification, install guide, and warranty.

Logistics & bundling: Wellco Wholesale supports mixed-SKU kitting (foil + tapes + vents + fiberglass), palletization, and contractor-friendly lead times to cut jobsite delays.

Case Snapshots (Anonymized)

Sunbelt metal warehouse retrofit

-

Before: Overheated floor, summer demand spikes.

-

Intervention: Under-roof foil with uninterrupted air space + added fiberglass at conditioned office.

-

Result: Cooling energy down ~9%, peak load down ~16% versus baseline bays; payback improved where demand charges are high.

Residential attic, mixed climate

-

Before: R-30 and comfort complaints.

-

Intervention: Top-up to R-49 plus rafter-line radiant barrier; ventilation preserved.

-

Result: Noticeably cooler second floor in late afternoons; lower run-time of upstairs air handler.

Expert Perspective

“Radiant barriers work best in hot climates and should be used in addition to recommended insulation levels—not instead of them.”

— U.S. Department of Energy, Energy Saver Guidance

Decision Framework & Quick Checklist

-

Confirm climate zone and code R target.

-

Identify roof assembly (metal/shingle), duct locations, and condensation risks.

-

Use fiberglass to hit R; add radiant barrier where solar gain or ducts justify it.

-

Specify details: air gap, ventilation, vapor control; cite ASTM tests on submittals.

-

Validate cost bands and lead times; consider Wellco Wholesale for bundled procurement and fewer POs.

Frequently Asked Questions

1) Can reflective foil replace fiberglass?

No. Foil targets radiant heat; fiberglass provides conductive resistance. Most projects need fiberglass to meet code R; foil is a supplement for hot roofs or where ducts are in the attic.

2) How big should the air gap be?

About ¾″–1½″ is common. The reflective surface must face an air space; direct contact with sheathing or insulation kills the radiant effect.

3) Will foil cause condensation problems?

Foil facers can be Class I vapor retarders. Place them on the correct side for your climate and maintain ventilation. Verify perm ratings and assembly drying paths.

4) Does foil help in cold climates?

Its main benefit is summer solar control and peak load reduction. In cold climates, focus on reaching R-49 to R-60 (per zone) with fiberglass; foil can still improve summer comfort.

5) What roll sizes and accessories should I order?

Common widths are 4–6 ft with 50–125 ft roll lengths. Don’t forget foil tapes, battens/spacers (to preserve the air gap), and ventilation components.

Sources (for further reading):

-

U.S. DOE — Energy Saver: Radiant Barriers & Reflective Insulation (accessed 2025)

-

Oak Ridge National Laboratory — field studies on radiant barriers & peak load reduction

-

IECC 2021/2024 — typical attic R-value guidance by climate zone

-

ASTM C1371, C518, E84/UL 723 — test methods and classifications

-

Building Science Corporation — guidance on vapor control (Class I/II/III)