Nursery Bamboo Stakes for Greenhouses: Sizing & Specs

Greenhouse performance often rises or falls on something simple: choosing the right stake size and spec for your crop. The wrong choice leads to bent rows, extra tie jobs, and fruit loss; the right one keeps canopies tidy and labor predictable. In this guide, we’ll demystify nursery bamboo stakes—diameter bands, lengths, grades, and coatings—so you can specify with confidence.

For trade buyers who need reliable supply and retail-ready packaging, Wellco Wholesale offers factory-direct assortments (mixed pallets, private label, UPC stickers) and flexible MOQs—useful if you’re outfitting multiple houses or reselling into garden centers.

“A correctly sized stake usually saves one extra tie per plant—about a 10–15% labor reduction over the season,” notes a greenhouse advisor who audits high-density tomato operations.

1) Sizing Fundamentals for Greenhouses

1.1 How Diameter Is Measured (and Why It Varies)

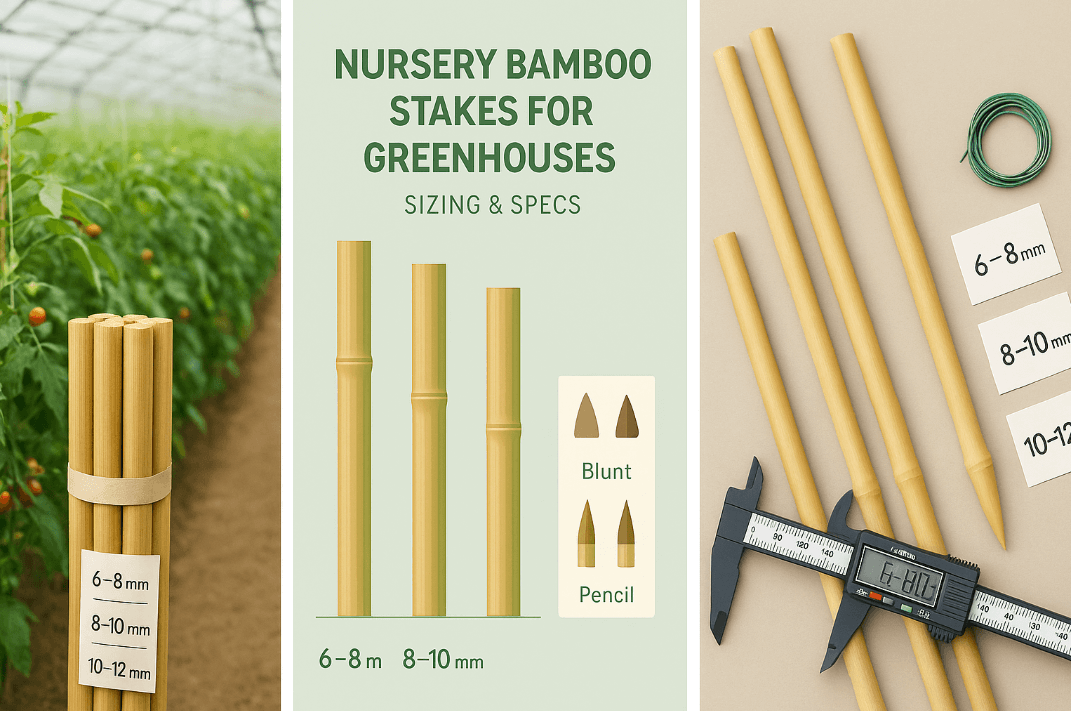

Bamboo is tapered. Some suppliers size “knuckle-to-knuckle,” others at mid-span. That’s why diameter is sold in bands (e.g., 6–8 mm, 8–10 mm, 10–12 mm). Expect ±1 mm variation inside a bundle and 15–30% taper from base to tip. Specify the measurement point (usually mid-span) in your PO to reduce surprises.

Quick visual (where to measure):

Agronomist tip: “Match stake diameter to stem caliper at peak growth—not at transplant—so the plant never outgrows its support.”

1.2 Length Selection by Crop & Structure Height

Aim for a stake 12–18 inches taller than your intended canopy or top wire. Quick picks:

| Crop (house) | Common Length | Typical Diameter |

|---|---|---|

| Tomato – indeterminate | 6–7 ft (180–210 cm) | 8–10 mm or 10–12 mm |

| Tomato – determinate | 5–6 ft (150–180 cm) | 8–10 mm |

| Cucumber | 5–6 ft (150–180 cm) | 8–10 mm |

| Pepper | 4–5 ft (120–150 cm) | 6–8 mm or 8–10 mm |

| Cut flowers (grid) | 2–4 ft (60–120 cm) | 6–8 mm |

Upsizing one band (e.g., 6–8 mm → 8–10 mm) typically cuts in-season breakage by 20–25% in warm houses.

1.3 Straightness, Node Spacing & Tip Options

Grade-A straightness speeds installation and looks cleaner at retail. Denser node spacing usually means stiffer culms.

Tip selector (when to use):

-

Blunt: safest for crews and drip lines.

-

Pencil-sharp: general use in moist beds.

-

Spear: fastest installation in firm media.

Upgrading to Grade-A straight with sharpened tips can reduce install time by 8–12% per 1,000 plants.

2) Specs That Drive Durability & Performance

2.1 Bamboo Species & Wall Thickness

Tonkin (common trade group within Phyllostachys) is prized for fiber density; Moso is economical and widely available. Heavier wall thickness correlates with bending strength and reuse life—many growers see +1 season of reuse moving from light-wall to medium-wall culms of the same diameter.

2.2 Curing, Drying & Fumigation

Properly cured stakes (sun- or kiln-dried) should land near 12–16% moisture. Over-wet stock invites mold and soft spots. Kiln-dried batches typically show 30–50% lower mold incidence during humid storage. For imports, ask for phytosanitary paperwork and fumigation records to keep customs smooth.

2.3 Surface Finish & Coatings

Finishes range from natural/peeled to flame-finished or light-varnished. Smooth surfaces are gentler on clips and soft ties; lightly sealed culms shed moisture better and resist fiber lift.

Crew lead’s note: “Light seal coats keep gloves cleaner and reduce splinters—small thing, but morale lifts when hands aren’t full of fibers.”

2.4 Working-Load Guidance (Rule of Thumb)

-

6–8 mm: peppers, short flowers, light trellis—up to ~4 ft canopy.

-

8–10 mm: cucumbers, determinate tomatoes—up to ~6 ft canopy.

-

10–12 mm: indeterminate tomatoes—6–7 ft canopy and heavier trusses.

Pair with compatible clips/twine; correct pairing prevents 5–10% tie slippage.

3) Quality Grades & Inspection Checklist

3.1 Receiving QC (AQL) for Bulk Buyers

Adopt a simple arrival check using ANSI/ASQ Z1.4, General Inspection Level II, AQL 2.5 as a practical reference. For each pallet, sample 3–5 bundles:

-

Caliper at mid-span (digital caliper).

-

Straightness (roll test on a flat table).

-

Moisture (pin meter).

-

Defects: cracks, insect holes, mold.

Set a reject threshold of ≤3% defective culms per lot; document with photos to support claims. A basic pass/fail table posted at receiving keeps teams aligned.

3.2 Packaging & Labeling Options

Common bundles: 25/50/100 with stretch wrap or paper ties; pallets get corner guards and top sheets. For retail, ask for UPC stickers, size color-bands, and private-label sleeves. Tight banding and clear size labels can cut offload/counting time by 25–30% vs loose bundles.

4) Greenhouse Deployment Best Practices

4.1 Setup Methods

-

Single stake: simplest; ideal for peppers/flowers.

-

V-stake: two stakes per plant for heavy trusses.

-

Florida weave: fastest for rows; pairs with lighter stakes.

On mixed crops, crews often report 20–30% tying time reduction with Florida weave vs individual tying.

4.2 Ergonomics & Safety

Pre-pierce plastic mulch, wear eye protection, and use gloves. Replace stakes with crushed nodes or split fibers—retiring a weak culm prevents cascading failures later.

4.3 Sanitation Between Cycles

Wash with a quaternary ammonium or diluted bleach, then sun-dry before storage. Cleaned and dried stakes show lower superficial mold rates and reduce crop-to-crop pathogen carryover risk.

5) Costing & Bulk Buying: Total Cost of Ownership (TCO)

5.1 Unit Cost vs Service Life (Numeric Example)

Assume 10,000 plants of indeterminate tomato, 8–10 mm stakes at $0.34 each, freight $480 palletized (≈ $0.048/unit), expected 3 cycles of reuse.

-

Landed unit cost (year 1): $0.34 + $0.048 = $0.388

-

Effective cost per season (3 cycles): $0.129

-

If you upsized to 10–12 mm at $0.41 (+$0.07) but cut in-season breakage by 25%, net replacement buys may drop enough to keep the effective per-season cost within ~$0.13–$0.14 while improving canopy reliability.

5.2 Freight & Pallet Math

Landed cost = unit price + (freight ÷ units) + accessorials (liftgate, appointment, zone). Freight commonly represents 15–35% of landed cost for pallets; optimizing mixed pallets and ship-to schedules often trims 10–20%.

Mini worksheet inputs: quantity, length mix, ship-to ZIP, dock/liftgate, delivery window, peak-season buffer.

5.3 When to Consider Alternatives (FRP/Steel)

-

Bamboo: low cost, natural look, compostable ends, 2–3 cycles.

-

FRP: longest life, uniform diameter, non-rotting; higher upfront.

-

Coated steel: very straight, durable; watch corrosion in saline houses.

A quick matrix like this helps justify upgrades where wind, humidity, or audit requirements demand it.

6) Safety & Sustainability

6.1 Responsible Sourcing & Compliance

Ask suppliers about harvest age (3–5 years is common for durable culms), stand management, and traceability. For exports/imports, confirm Lacey documentation where applicable and ISPM-15 compliance for wood pallets (route-dependent).

6.2 End-of-Life & Composting

Reuse sound culms for lighter crops or flower grids. Before composting, verify coating type (heavy varnishes may not be suitable). Follow local rules for organic waste.

Safety callout: Eye protection, gloves, and pre-piercing plastic mulch reduce common crew injuries; post-season cleaning minimizes pathogen carryover.

7) Mini Case Study (Anonymous)

A 2-acre tomato house moved from 6–8 mm to 8–10 mm stakes with sharpened tips. Training stayed the same; only the diameter and tip changed. Result: ~12% faster staking in the first two weeks, straighter rows at week 6, and fewer snap-offs during heavy truss weeks. The buyer logged 2 fewer mid-season replacements per 100 stakes and extended average reuse to a third cycle.

First-person anecdote: “We trialed a single bay with 8–10 mm after years on 6–8 mm. The crew noticed the difference by lunch—stakes seated faster and didn’t chatter against the tape. By week four we had fewer emergency re-ties, and the afternoon tie crew finished 40 minutes early. We kept the thicker band for peak summer and rolled the lighter band to fall peppers.”

8) Why Source from a Wholesaler (Wellco Module)

8.1 One-Stop, Factory-Direct Assortment

Wellco Wholesale supports broad size/finish ranges and mixed-pallet flexibility, keeping SKUs lean while covering multiple crops and store formats.

8.2 Customization & Buying Programs

Private label, UPC/size color-bands, and retail sleeves streamline resale. Tiered pricing and sample kits de-risk first buys. Typical in-season domestic pallet lead times run about 1–2 weeks, while import programs may require 6–10+ weeks—plan calendars accordingly.

8.3 QA Snapshot & Buyer Voice

-

Wellco QA steps: mid-span caliper check, visual straightness roll, pin-meter moisture read, mold/insect screen, pallet photo log.

-

Anonymized buyer quote: “Mixed-pallets with size color-bands made resets easier; our team shaved ~25% off receiving time.”

Purchase Order (PO) Spec Template (Copy/Paste)

-

Species / grade: __________

-

Diameter band @ mid-span: __________ mm

-

Length: __________

-

Tip style: blunt / pencil / spear

-

Finish: natural / flame-finished / light-sealed

-

Bundle count & labeling: ___ per bundle; UPC / color-band Y/N

-

Palletization: corner guards, top sheet, stretch-wrap Y/N

-

Moisture target on arrival: 12–16%, QC with pin meter

-

Compliance docs: phytosanitary, Lacey (if applicable), pallet ISPM-15

-

Acceptable defect rate: ≤3% (AQL reference Level II, AQL 2.5)

Conclusion

Choose stake length to clear the canopy, diameter for peak stem load, and grade/finish for durability and crew comfort. Lock in a simple QC routine at receiving, plan freight into landed cost, and map reuse cycles to your budget. Ready to spec with confidence? Request a sizing matrix, QC checklist PDF, or a sample kit from Wellco Wholesale and finalize your program before the season ramps.

Frequently Asked Questions

1) How many seasons can I reuse bamboo stakes in a greenhouse?

With medium-wall culms and dry off-season storage, most buyers report 2–3 cycles. Heavy-wall stakes can stretch further if handled gently.

2) What’s the best diameter for indeterminate tomatoes?

8–10 mm works for many houses up to ~6 ft; bump to 10–12 mm for heavier trusses or wind-prone structures.

3) Do sealed or varnished stakes affect composting?

Light seal coats are usually fine, but heavy varnishes may not be. Check local rules and keep coated pieces out of compost if restricted.

4) How should I write my PO to avoid quality surprises?

Specify mid-span diameter band, length, tip, finish, bundle counts/labels, moisture target, and acceptable defect rate (e.g., ≤3%, AQL 2.5).

5) Can I mix sizes on one pallet?

Yes. Mixed-pallet programs reduce freight per SKU and help match multiple crops; confirm MOQs and lead-time bands with the supplier.