Your Trusted Wholesale Partner

Discover a wide range of industrial and garden supplies at Wellco Wholesale. Buy directly online or request custom orders — reliable quality, competitive pricing, and flexible service for every need.

From the Blog

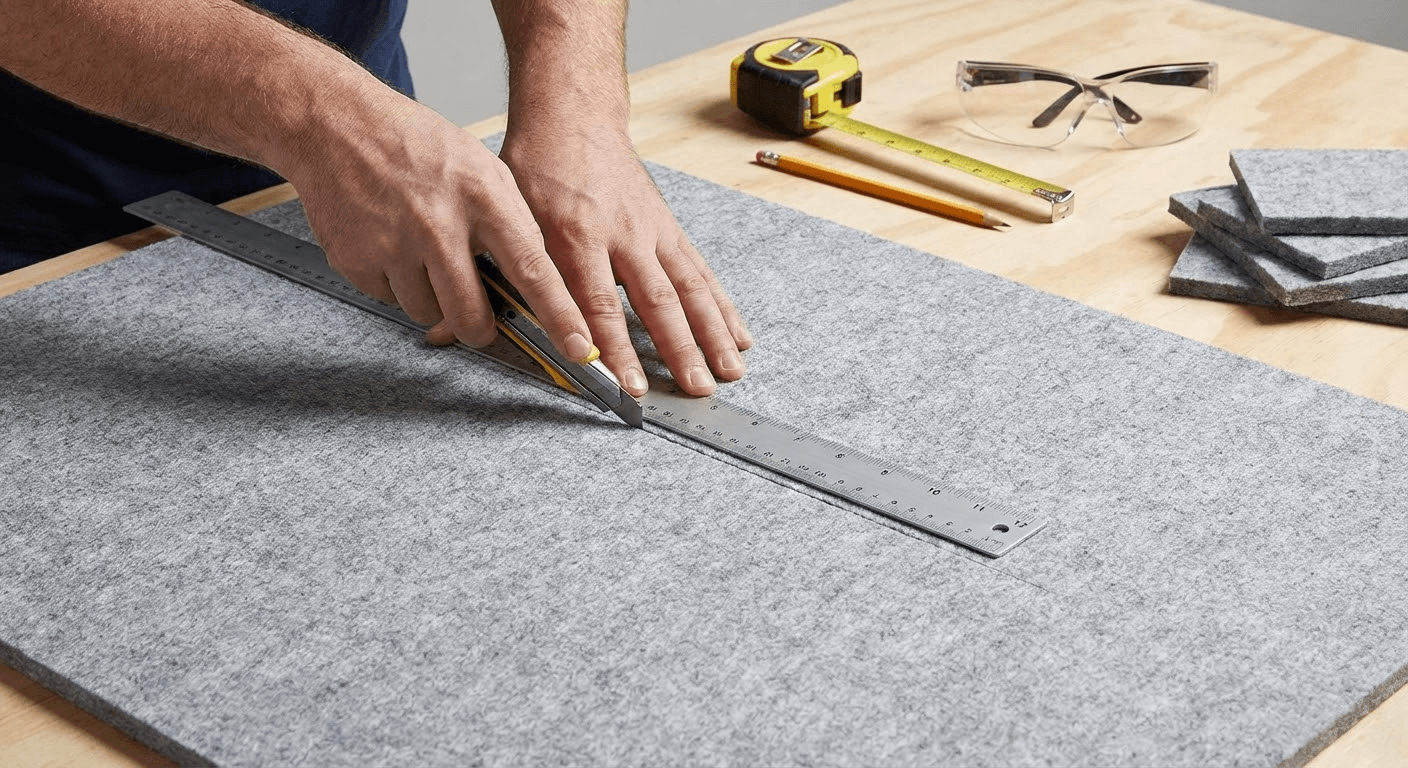

A clean-looking acoustic panel job usually comes down to one unglamorous skill: cutting. When edges fray, seams wander, or outlet cutouts land a hair off, even premium panels can look “DIY.” This guide shows how to cut acoustic panel materials cleanly and safely—whether you’re trimming a few panels for a home studio or sizing dozens for a commercial space.

At Wellco Wholesale, we support both trade customers buying in bulk and individual retail buyers sourcing project materials, so we’ve seen the same issues repeat: dull blades, rushing measurements, and using the wrong method for the panel type.

Who / How / Why (Transparency)

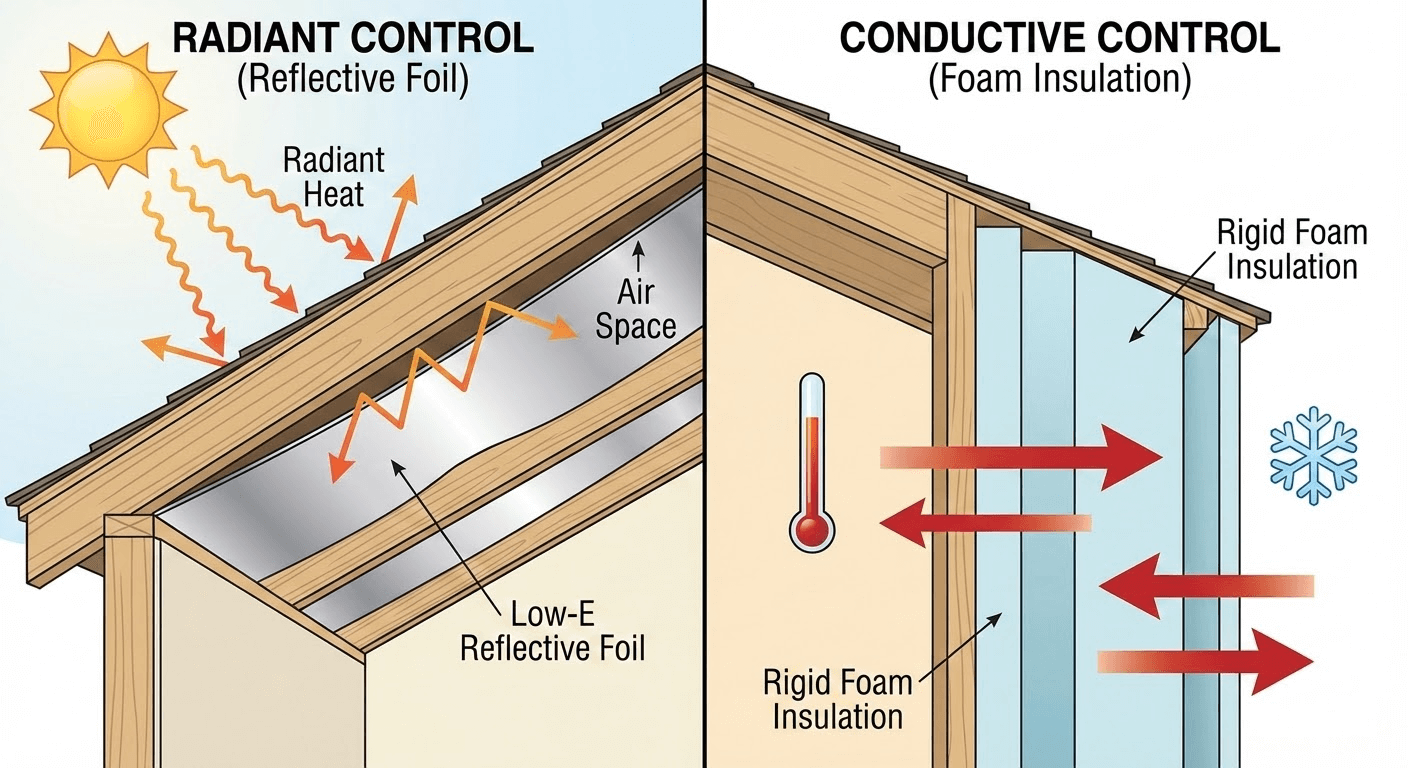

Walk into a metal shed at 4 p.m. in midsummer and you can feel heat radiating off the roof like a broiler. That discomfort often isn’t just “hot air”—it’s radiant heat pouring in from sun-baked surfaces. Double sided reflective foil insulation can be a fast, practical tool to reduce that radiant load when the assembly is built for it. When it’s installed wrong (usually with no air space), it becomes an expensive shiny layer with disappointing results.

This article is for trade and bulk buyers—contractors, agricultural operators, greenhouse builders, landscapers, and light-building crews—plus serious DIYers who want pro-level outcomes. You’ll get a clear “when it works” decision guide, what specs matter for purchasing, and installation details that actually control performance.

Pepper plants can look perfectly upright for weeks—then one gusty day or a sudden heavy fruit set bends a main stem and snaps your best branch right where it forks. Bamboo stakes for pepper plants are a low-cost, high-impact way to prevent that kind of mid-season loss, while also improving airflow and making harvests less of a scavenger hunt under the canopy.

Who this is for: home gardeners, market growers, landscapers, and trade buyers who want a simple support method that scales.

How this guide was built: hands-on staking across containers, raised beds, and in-ground rows (plus what consistently failed), combined with widely used university-extension style best practices—especially around staking early and gentle ties.

Why bamboo: it’s lightweight, easy to cut/handle, and simple to standardize by le

If your room sounds “echoey,” your voice feels sharp on calls, or recordings have that hollow bedroom bounce, acoustic foam panels can improve clarity quickly. They reduce reflections and flutter echo, which makes speech easier to understand and mic recordings less “roomy.” You will still hear traffic outside your window because foam is not designed for isolation, yet you can absolutely make a small space sound more controlled with smart placement.

I like to start every install the same way: record a 20 second voice clip on your phone and do a quick clap test in your usual speaking spot. After installation, repeat the same tests in the same position. That simple before and after check keeps you honest about what changed and helps you avoid overbuying.

If you’re outfitting multiple rooms or buying for a team, consistency becomes part of the “sound quality.” Bulk buyers usually care about un

If your building feels like a heat lamp in the afternoon or a fridge at sunrise, you’re already asking the right question: which insulation strategy fits the physics and the jobsite reality. This guide compares low-e reflective foil insulation vs foam for trade buyers and bulk purchasers, including contractors, facility teams, farm and greenhouse operators, and light building suppliers.

You’ll get a fast decision flow, install do’s and don’ts, a troubleshooting cheat sheet, plus an RFQ spec list you can copy into purchasing. Wellco Wholesale supports one stop, factory direct wholesale buying across agricultural, gardening, landscaping, and light building supplies, which is useful when you want insulation plus the tapes, fasteners, and jobsite consumables to match.

Acoustical Panels

Acoustical Panels  Bamboo Stake

Bamboo Stake  Burlap & Jute

Burlap & Jute  Fiberglass Fire Blankets

Fiberglass Fire Blankets  Fiberglass Grating

Fiberglass Grating  Fiberglass Stake

Fiberglass Stake  Garden Netting

Garden Netting  Insulation

Insulation  Rebar

Rebar  Shade Cloth

Shade Cloth  Snow Markers

Snow Markers  Weed Barrier Fabric

Weed Barrier Fabric