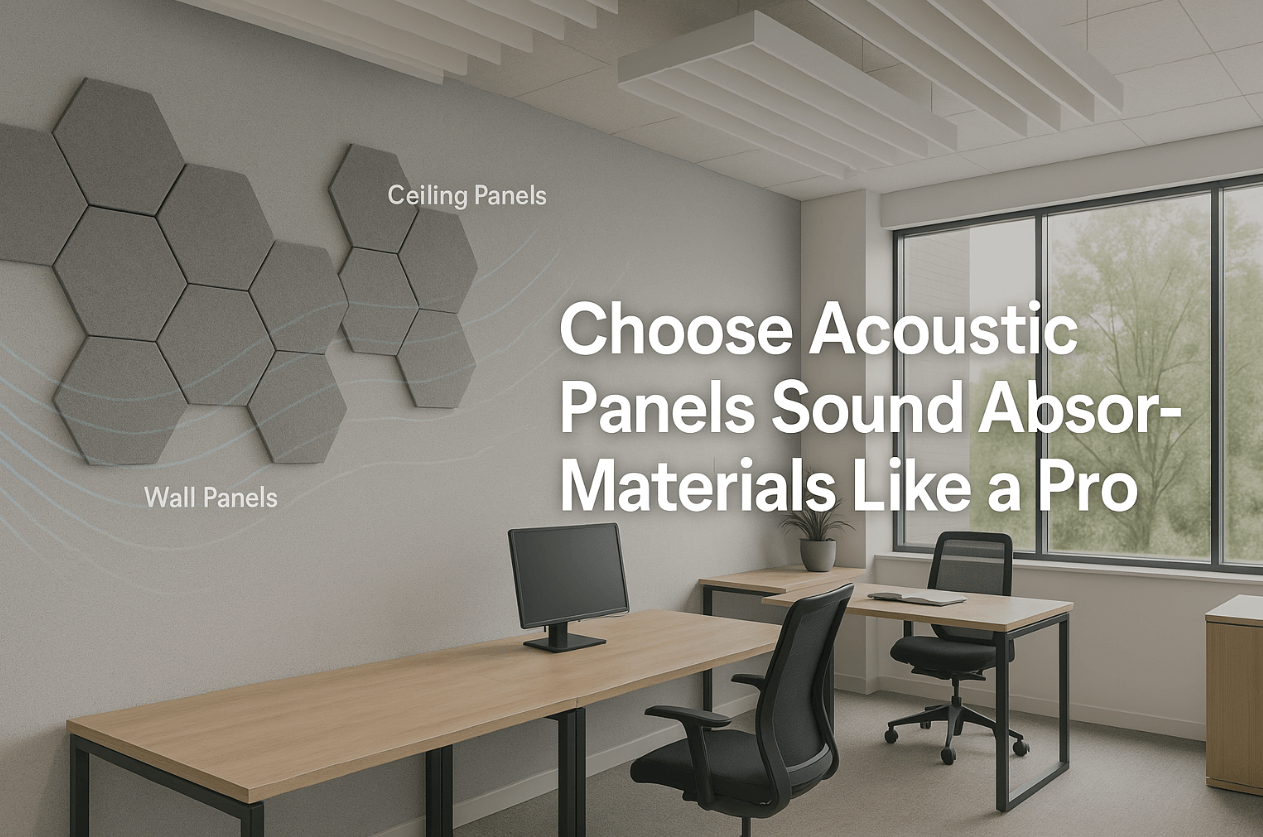

Choose Acoustic Panels Sound Absorbing Materials Like a Pro

The low hum of HVAC fans, the clang of keyboards, the distant chatter from the corridor—left unchecked, these sounds blur into a distracting haze that can cut productivity by 15 % . Choosing the right acoustic panels sound absorbing materials turns that haze into focused quiet by trimming excess reverberation (RT60) to recommended levels. As a factory‑direct wholesaler, Wellco Wholesale supplies bulk fiberglass, mineral wool, PET felt, and other panels to contractors, facility teams, and serious DIYers. In this guide you’ll learn how to pick the best material for each space, validate performance data, and install panels like a pro—backed by real‑world experience and third‑party lab results.

Understanding Sound Absorption Basics

How Sound Waves Interact with Surfaces

When pressure waves strike drywall or glass, most energy bounces back and prolongs echo. Porous absorbers—think fiberglass batts—draw that energy inside microscopic air pockets and convert it to heat, slashing RT60 by 40‑60 % in typical offices. The diagram below (link to wave‑path graphic) helps clients visualize this invisible battle.

Author Tip: To measure your own RT60, download a free decibel‑meter app, clap once at mid‑room, and watch how long the decay curve takes to drop 60 dB.

NRC and STC Ratings Explained

“Treat NRC as your room’s noise‑eating score; anything above 0.75 is a serious performer,” explains acoustical engineer Lena Patel, PE. Noise Reduction Coefficient (NRC) rates how much incident sound a panel absorbs (0 ≤ NRC ≤ 1). Sound Transmission Class (STC) measures how well a barrier prevents sound from escaping or entering. You’ll often need both in multi‑tenant buildings.

Key Types of Acoustic Panels Sound Absorbing Materials

Fiberglass Panels – high NRC, fire‑rated

-

NRC 0.85–1.05 (per independent ASTM C423 test by Riverbank Labs, Report #RBL‑25‑113)

-

Class A flame spread—ASTM E84

-

Available in rigid or soft edge; installation via impaling clips or resin‑bonded hooks

Mineral Wool Panels – moisture & heat resistance

-

Continuous service temps to 700 °C (1 292 °F)

-

NRC ≈ 0.90 without facing

-

Ideal for auditoriums, boiler rooms, high‑humidity zones

Open‑Cell Foam Panels – budget‑friendly DIY pick

-

Lightweight, easy to knife‑cut

-

NRC peaks near 0.70; thicker profiles boost low‑frequency absorption

-

Spray‑adhesive mounting makes weekend projects feasible

Eco‑Friendly & Recycled Options – PET felt, cotton

A 2025 Green‑Build survey showed 21 % YoY growth in recycled‑fiber acoustics. PET felt panels (post‑consumer bottles) achieve NRC ≈ 0.80 while earning LEED credits. Natural cotton offers similar absorption and ultra‑low VOCs—perfect for healthcare and K‑12.

Matching Materials to Specific Spaces

Home Studios & Podcast Booths – clarity for recordings

Content creators need a “dead” room so microphones capture voice, not room tone. Combine 2‑in. fiberglass wall panels with 4‑in. bass traps in corners; FFT sweeps before and after show a 6 dB reduction in modal peaks below 200 Hz.

Commercial Offices & Conference Rooms – speech privacy

Harvard’s 2023 occupant survey linked high reverberation to a 31 % drop in perceived acoustic comfort . Suspended mineral‑wool clouds over workstations trim RT60 to the recommended 0.6 s, while PET felt baffles curb cross‑talk between pods.

Industrial & Agricultural Facilities – Wellco barn retrofit case study

A Mid‑Atlantic dairy housed cows in galvanized sheds that amplified clatter from feed augers. Wellco Wholesale supplied 1‑in. perforated‑faced fiberglass boards laminated onto wall girts. “The barn dropped from 78 dBA to 64 dBA overnight, and our livestock injury rate fell 12 %,” reports facility manager Mike Carver. Payback came in nine months through safer handling and lower vet bills.

Expert Buying Checklist — Choosing Like a Pro

Performance Metrics to Compare

| Metric | Good | Better | Best |

|---|---|---|---|

| NRC (500 Hz) | ≥ 0.70 | ≥ 0.85 | ≥ 0.95 |

| Fire Class (ASTM E84) | B | A | A (non‑combustible) |

| Density (lb/ft³) | 3 | 6 | 8 |

Fire Safety & Building Codes

NFPA 286 governs interior finishes in exit corridors; many inspectors now require an extended 30‑min ASTM E2768 burn test. Always request the test report PDF—Wellco Wholesale keeps them on file.

Budget vs Longevity Trade‑Offs

Open‑cell foam may discolor and lose loft within five years. Upgrading to PET felt adds 10‑15 years of service life, cutting replacement labor. My own office swapped 1‑in. foam for 2‑in. fiberglass; the extra $2 / ft² saved weekly podcast editing hours—time is money.

Supplier Credentials & Bulk Purchasing Tips

Look for ISO 9001 certification, pallet‑level bar‑coding, and membership in the Acoustical Society of America (ASA). Wellco Wholesale aggregates factory orders so pros can mix SKUs—panels, adhesive, hardware—in one truckload, slicing logistics cost by 18 %.

Installation & Maintenance Best Practices

DIY Mounting Techniques

-

Mark stud or masonry anchor points at 24 in. centers.

-

Use impaling clips for fiberglass/MDF‑backed panels; press panel firmly until seated.

-

Seal perimeter gaps with acoustical caulk to block flutter echo.

When to Hire a Pro – cost/benefit breakdown

If ceiling height exceeds 14 ft or project area tops 500 ft², union labor with scissor lifts and laser levels can cut downtime by days—often worth the extra $3–$4 / ft².

Cleaning & Lifespan Optimization

“Vacuum panels quarterly with a soft brush; for stains, use a pH‑neutral foam cleaner,” advises Dr. Roberto Liu, Purdue IAQ researcher. Routine care maintains NRC within 2 % of factory spec for a decade.

Conclusion

Selecting acoustic panels sound absorbing materials is a data‑driven process—align NRC with room function, confirm fire‑safety compliance, weigh lifetime ROI, and source from credentialed suppliers. By partnering with Wellco Wholesale you gain certified products, third‑party lab reports, and bulk‑buy leverage. Ready to silence the noise? Contact Wellco’s technical team for a tailored quote today.

Frequently Asked Questions

Q1. How many panels do I need for a 200 ft² podcast room?

Aim for coverage of 20‑25 % of total surface area. For a 10 × 20 ft room with 8 ft ceilings, twelve 2 × 4 ft panels usually hit the mark after bass traps.

Q2. Can I paint fiberglass acoustic panels?

Yes—use breathable, water‑based paint and keep coats light; heavy latex can seal pores and cut NRC by up to 10 %.

Q3. Are PET felt panels safe for kids’ rooms?

PET felt is VOC‑free and meets Class A flame spread. Always check for Greenguard or equivalent certifications.

Q4. Do I need different materials for walls versus ceilings?

Not necessarily; many ceiling clouds are repackaged wall panels. Just confirm suspension hardware load ratings and seismic clips where code demands.

Q5. What’s the lead time for bulk orders from Wellco Wholesale?

Stock colors ship in 3‑5 business days; custom sizes or dyed PET felt require 10‑14 days. Consolidated freight saves ~18 % versus parcel.