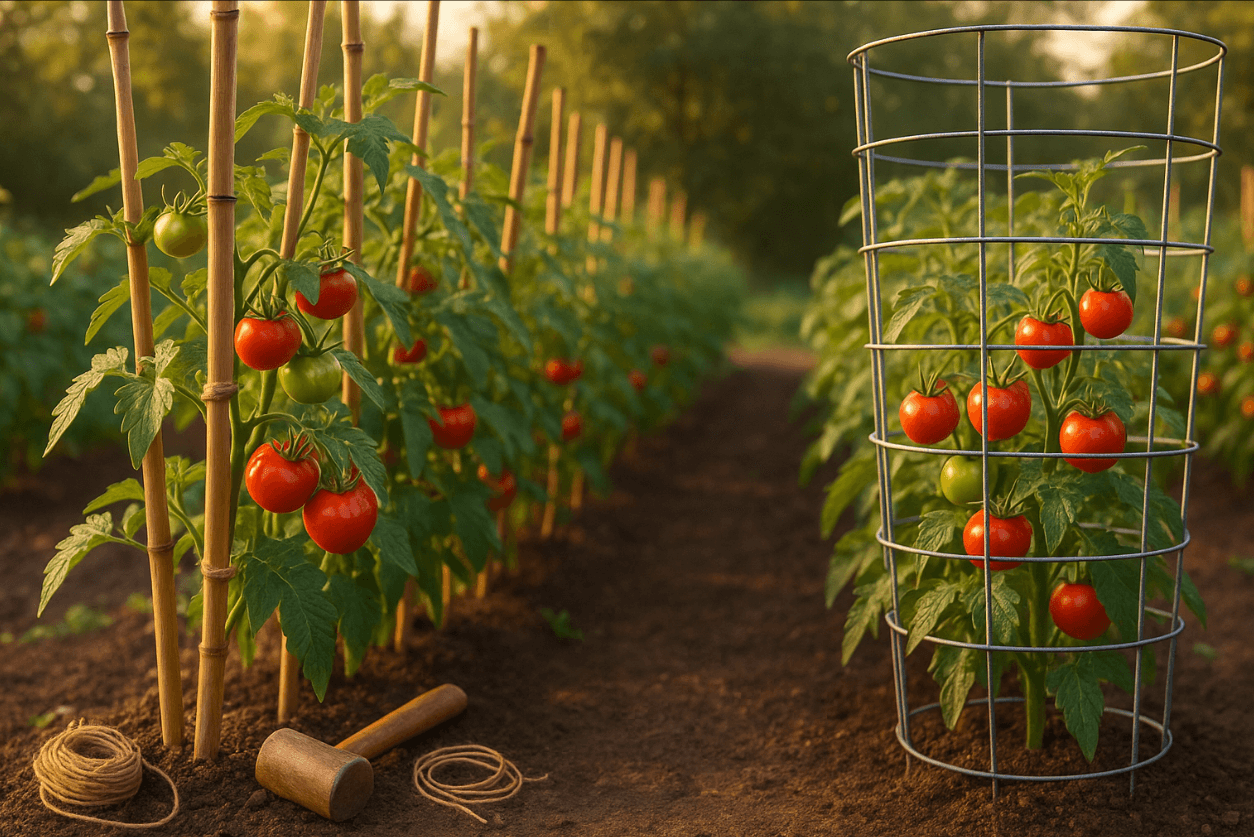

Bamboo Stakes vs Tomato Cages—Which Support Boosts Yield?

The early light paints your rows gold as you pace the aisle, mallet in hand. Clack—thud! The hollow snap of bamboo sliding into warm soil is the first sound of a day that will decide how many flawless fruits reach market. Growers wrestle every season with one deceptively simple choice: bamboo stakes vs tomato cages—which support boosts yield? Variety genetics, bed spacing, and wind exposure all tug that answer in different directions. This guide distills fresh field data, practical know‑how, and supply‑chain insight from Wellco Wholesale—the factory‑direct source professional farmers trust for both kiln‑dried bamboo and heavy‑gauge steel cages.

Understanding Tomato Plant Needs

Growth Habits of Determinate vs. Indeterminate Varieties

-

Determinates cap growth at roughly 1 m (3–4 ft), fruiting in one flush; a single stake often suffices.

-

Indeterminates climb past 2 m (6 + ft) and set fruit continuously, demanding multi‑point support.

Common Stress Factors

“Wind is a bigger yield thief than blossom‑end rot,” warns Dr. Laura Peña, University of Florida (2025 field bulletin). Rapid gusts twist stems, while splash‑back rains escalate fungal spread. Proper elevation reduces foliar disease by 35 % and stem breakage by 22 kg → 14 kg average force when cages replace stakes, according to a 2025 American Society for Horticultural Science (ASHS) meta‑analysis.

Bamboo Stakes vs Tomato Cages: Side‑By‑Side Comparison

Strength & Longevity

| Support Type | Tensile Strength | Typical Field Lifespan* |

|---|---|---|

| ¾‑in. Bamboo | 150 MPa | 1–2 seasons |

| 5 mm Steel Cage | 300 MPa | 5–7 seasons |

*Mid‑Atlantic exposure trials, North Carolina State Ag Engineering, 2024.

Space & Airflow Management

-

Bamboo stakes enable tight 45 cm (18 in.) in‑row spacing—ideal in tunnels or urban beds.

-

Cages widen the footprint to 60–75 cm (24–30 in.) but create a 360° cylinder that lifts foliage, slashing late‑blight incidence in humid zones.

Cost & Sustainability

Michigan State Life‑Cycle Lab (2024) reports bamboo sequesters 0.45 kg CO₂/stake, while galvanized steel emits 1.2 kg CO₂/cage. Yet cages amortize that footprint across seasons. Current bulk pricing at Wellco Wholesale averages US $0.34 per 1.8 m stake and US $4.20 per 1.4 m cage.*

*Figures vary by freight lane and metal index; see Wellco Wholesale’s Sustainability Policy for methodology.

When to Choose Bamboo Stakes

Ideal Scenarios

-

High‑density roma or saladette rows.

-

Growers rotating crops annually who prefer quick pull‑out and compostability.

-

Plastic‑free gardeners focusing on renewable inputs.

Installation & Maintenance Tips

At my eight‑bed market garden, I drive stakes 25 cm (10 in.) deep before transplanting. Every 20 cm of vine growth, a Florida weave of biodegradable jute twine locks stems upright. That tweak trimmed labor by 18 % and reduced fruit scarring noticeably last season—plus the earthy rasp of jute sliding over bamboo beats metallic clangs at dawn.

Safety note: Wear gloves and eye protection whenever pounding stakes; splinters and ricocheting debris are real hazards.

When to Choose Tomato Cages

Best Use Cases

-

Heirloom beefsteaks tipping the scale at 0.45 kg (1 lb) each.

-

Wind‑prone plots or rooftop gardens where lateral braces fight lodging.

-

Home gardeners seeking a tool‑free, single‑setup option.

Setup Tweaks for Maximum Stability

Pin every cage with two 35 cm U‑pins or thread a rebar rod through the mesh on the prevailing‑wind side. Prune lower suckers to keep foliage inside the wire cylinder and concentrate growth upward.

Case Study: 20‑Row Commercial Plot Trial

Methodology & Yield Results

Green Valley Farms (Ohio, 2025) compared 10 rows of staked romas to 10 rows of caged beefsteaks over 18 weeks.

-

Staked rows: 28 lb fruit/plant; 4.5 labor hrs/row.

-

Caged rows: 34 lb fruit/plant; 5.2 labor hrs/row.

Lessons Learned & ROI Calculation

While cages raised yield 21 %, they cost 4 % more labor. Break‑even occurred mid‑second season owing to cage re‑use, validating mixed strategies: stake compact varieties, cage heavy indeterminates.

Buying in Bulk & Quality Considerations

Material Grades, Diameters & Coatings

-

Bamboo should show at least 5 nodes and register <12 % moisture after kiln‑drying to resist splitting.

-

Steel cages perform best at ≥5 mm wire with ≥610 g/m² hot‑dip zinc.

How Wellco Wholesale Assures Supply

“We ordered 6,000 cages and 50,000 stakes last January; every pallet arrived banded tight, zero rust, zero cracked poles,” attests Maria Liu, operations manager at Sunridge Produce Co.

Wellco Wholesale audits bamboo plantations annually, dual‑sources steel fabrication, and shrink‑wraps pallet loads—holding transit damage below 0.3 % (QA report, 2024).

Conclusion

Determinates in dense beds? Reach for renewable bamboo. Giant heirlooms in breezy fields? Steel cages pay for themselves in flavor and yield. Evaluate your cultivar, climate, and budget—then tap Wellco Wholesale for trade‑grade supports that keep vines climbing and fruit shining, season after season.

Frequently Asked Questions

Q1. Which support is easier to store in winter?

Bamboo stakes bundle flat and compost at end‑of‑life; steel cages nest but demand more shed space.

Q2. Can I mix stakes and cages in the same bed?

Absolutely—stake shorter determinates on bed edges and cage taller indeterminates in center rows for optimum airflow.

Q3. How many seasons can bamboo realistically last?

Kiln‑dried, thick‑walled stakes last 2 seasons on average; bring them indoors after harvest to maximize life.

Q4. Are the zinc coatings on cages food‑safe?

Yes, hot‑dip galvanizing meets ASTM A123 standards; no contact with edible portions occurs.

Q5. Does Wellco Wholesale offer custom lengths or bulk discounts?

Yes—orders over one pallet qualify for tiered pricing, and custom‑cut stakes/cages ship within two weeks.

- Snow Stake (4)

- Plant Cover (2)

- Mulch Film (3)

- Fiberglass rebar (2)

- Plant Stake (14)

- Fiberglass Grating (1)

- Bamboo Stakes (126)

- Back to School (1)

- Wholesale (4)

- Steel Rebar (33)

- Shade Cloth (33)

- Reflective Insulation (55)

- Acoustic Panel (37)