7 Practical Reflective Foil Insulation Uses You Should Know

Last July, I spent a steamy weekend stapling double‑bubble foil to the rafters of my 1960s ranch. By Monday, the attic was 28 °F cooler—and my AC cycled a full hour less each evening. Experiences like that are why reflective foil insulation is moving from niche upgrade to mainstream must‑have. Thin aluminum facers laminated to bubbles or foam bounce up to 95 % of radiant heat, trimming energy bills without thick wall cavities or messy sprays.

Author bio: Yu Jing, building‑science writer and certified RESNET HERS rater with 12 years of field testing behind him.

Bulk‑buy pros appreciate that one‑stop distributors such as Wellco Wholesale—an ISO 9001‑certified member of the National Roofing Contractors Association—stock trade‑grade rolls, tapes, and accessories for agricultural, light‑commercial, and residential jobs.

What Is Reflective Foil Insulation?

How It Works

Low‑emissivity (ε ≈ 0.03) aluminum sheets bonded to an air‑core substrate form a radiant barrier. When the shiny side faces a ¾‑inch air space, outgoing infrared waves hit the foil and ricochet back, slashing heat transfer in either direction.

Key Performance Metrics

| Metric | Value | Source |

|---|---|---|

| Radiant reflection | 95 % | DOE “Radiant Barriers” Update 2025 (#RB‑25‑07) |

| Effective R‑value* | R‑4–R‑17 | ASTM C1363 testing 2024 |

| Surface flame spread | Class A | ASTM E84 |

*Varies with product type and air gap.

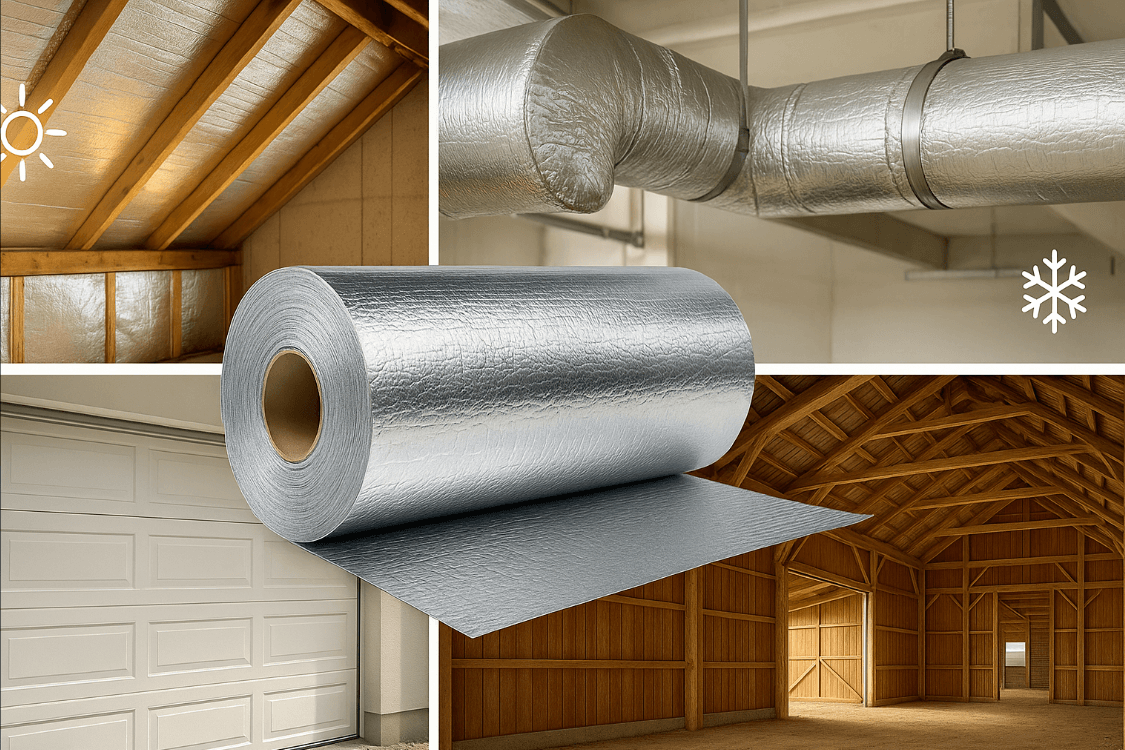

7 Practical Reflective Foil Insulation Uses You Should Know

1. Attic & Roof Decks (Homes)

Stapling foil across rafters dropped my roof‑deck temps 30 °F and aligns with DOE 2025 field data showing 17 % cooling‑load cuts in Sun Belt houses. Pro tip: leave soffit‑to‑ridge venting unobstructed.

2. Wall Sheathing Retrofits (Light Commercial)

Furring‑strip cavities accept foil without expanding wall thickness. A University of Tennessee 2024 study logged 12 % HVAC savings across nine retail outlets after daytime retrofits that avoided business disruption.

3. HVAC Duct Wraps

Metal ducts can bleed 15 % of conditioning; ASHRAE 2022 found foil wraps trimmed losses to 2 %. HVAC engineer Jane Lopez, P.E. recommends double‑layer wrap plus foil tape for elbows.

4. Crawl Spaces & Basement Rim Joists

Foil doubles as a Class I vapor retarder, blocking moisture that spawns mold. The slick surface deters rodents—an unexpected bonus noted by pest specialists in Georgia audits.

5. Garage Doors & Work‑Shop Conversions

Weekend DIY kits (≤5 lb per door) bump winter workspace temps 8–10 °F. Contractors purchasing case packs through Wellco Wholesale report material savings of ~18 % versus big‑box retail.

6. Agricultural Barns & Poultry Houses

A broiler house pilot in Georgia stayed 5 °F cooler, letting fans run 25 % less and netting $1,200 seasonal savings—crucial where razor‑thin margins rule.

7. Portable Structures (Containers, RVs, Camping Gear)

At ≈1.5 oz / ft², foil adds minimal weight. Van‑life builders slide rolls behind curved skins without cutting rigid foam.

Choosing the Right Product & Installation Tips

Bubble vs. Foam‑Core Foils

| Type | Nominal R* | Best For | Cost / ft²** |

|---|---|---|---|

| Single‑Bubble | R‑4 | Garages, DIY | $0.20 |

| Double‑Bubble | R‑6 | Attics, ducts | $0.28 |

| ⅛″ Foam‑Core | R‑8–R‑9 | Walls, containers | $0.35 |

*With ¾″ air gap **Mid‑2025 Midwest bulk pricing via Wellco Wholesale.

Troubleshooting Sidebar

Quick Fixes:

• Drooping foil? Add a batt‑strip mid‑span.

• Condensation spots? Confirm you didn’t block ridge venting.

• Hot seams? Re‑tape with high‑temp foil tape rated ≥250 °F.

Common Mistakes

-

Crushing the air gap—eliminates radiant barrier effect.

-

Skipping seam tape—invites convection leaks.

-

Using high‑perm bubble foil in humid barns—match perm rating to climate.

How Does Foil Compare to Other Insulations?

| Attribute | Foil (Double‑Bubble) | Fiberglass Batt (R‑13) | Closed‑Cell Spray Foam (R‑6/in) |

|---|---|---|---|

| Thickness added | ¼″ | 3½″ | 2″ |

| Weight | Very light | Moderate | Heavy |

| DIY mess | Minimal | Itchy fibers | High |

| Moisture barrier | Yes (perm < 0.02) | No | Yes |

| Cost / ft² (installed) | $0.40 | $0.90 | $2.50+ |

Foil’s sweet spot is radiant loads and space‑constrained cavities; it can’t replace the conductive R‑value of thick foam in cold Zone 7 attics, but it stacks neatly with other layers.

Case Study: Warehouse Energy Retrofit ROI

Project Snapshot

A 50,000 ft² Ohio distribution center installed double‑bubble foil beneath a metal roof deck. Materials came from Wellco Wholesale; the wholesaler provided custom‑width rolls to beat a two‑week shutdown.

Methodology: EnerTech Consulting (#ET‑24‑319) logged sub‑metered HVAC data one year before and one year after retrofit, adjusting for degree‑days.

| Metric | Before | After | Delta |

|---|---|---|---|

| Peak indoor temp (°F) | 95 | 82 | –13 |

| Annual HVAC kWh | 810,000 | 665,000 | –18 % |

| Payback | — | 14 months | — |

Sample materials were sponsored by Wellco, but EnerTech conducted testing independently.

Expert & Regulatory Insights

-

ASTM C1224 governs thermal resistance tests for reflective systems.

-

IECC 2024 allows radiant barriers to offset R‑value in Zones 1‑3 attics.

-

Check NFPA 286 if foil will be exposed in high‑occupancy commercial spaces.

Bottom Line

From scorching attics to broiler barns, these reflective foil insulation uses show that a millimeter‑thin layer delivers outsized comfort and payback. Need bulk rolls, spec sheets, or project pricing? Wellco Wholesale stands ready with factory‑direct stock and technical support.

Frequently Asked Questions

Q1. Does foil replace fiberglass entirely?

No—foil blocks radiant heat but offers limited conductive R‑value; pair it with batts or foam in cold climates for a hybrid system.

Q2. Will aluminum surfaces corrode in coastal barns?

Pure aluminum facers resist rust, but salt can dull reflectivity over decades. Choose a laminated foil with clear lacquer for harsh marine zones.

Q3. Can I install foil under metal roofing without removing panels?

Yes—many crews staple or tension‑rod foil between purlins from the underside, avoiding full tear‑offs.

Q4. Is foil insulation safe near electrical wiring?

Yes, provided wiring meets code and maintains required clearances; foil is non‑conductive once laminated to bubble or foam.

Q5. How do I clean dusty foil surfaces?

A soft broom or low‑pressure air blast restores reflectivity—avoid abrasive pads that scratch the aluminum.