7 Benefits of Reflective Aluminum Foil Insulation

Energy budgets keep climbing, yet comfort and crop protection remain non‑negotiable for growers, contractors, and homeowners. Reflective aluminum foil insulation offers a fast‑acting shield against radiant heat, giving buildings a cooler summer and a warmer winter without overloading HVAC systems. As a factory‑direct wholesaler, Wellco Wholesale supplies trade buyers with bulk rolls that meet rigorous performance specs, making large‑scale projects simpler and more affordable.

What Is Reflective Aluminum Foil Insulation and How Does It Work?

Structure & Materials Explained

A typical roll is a sandwich of one or two layers of polished aluminum bonded to a polyethylene or woven core. The shiny surface has an emissivity as low as 0.03, meaning it emits only 3 % of the heat striking it—far less than drywall or OSB.

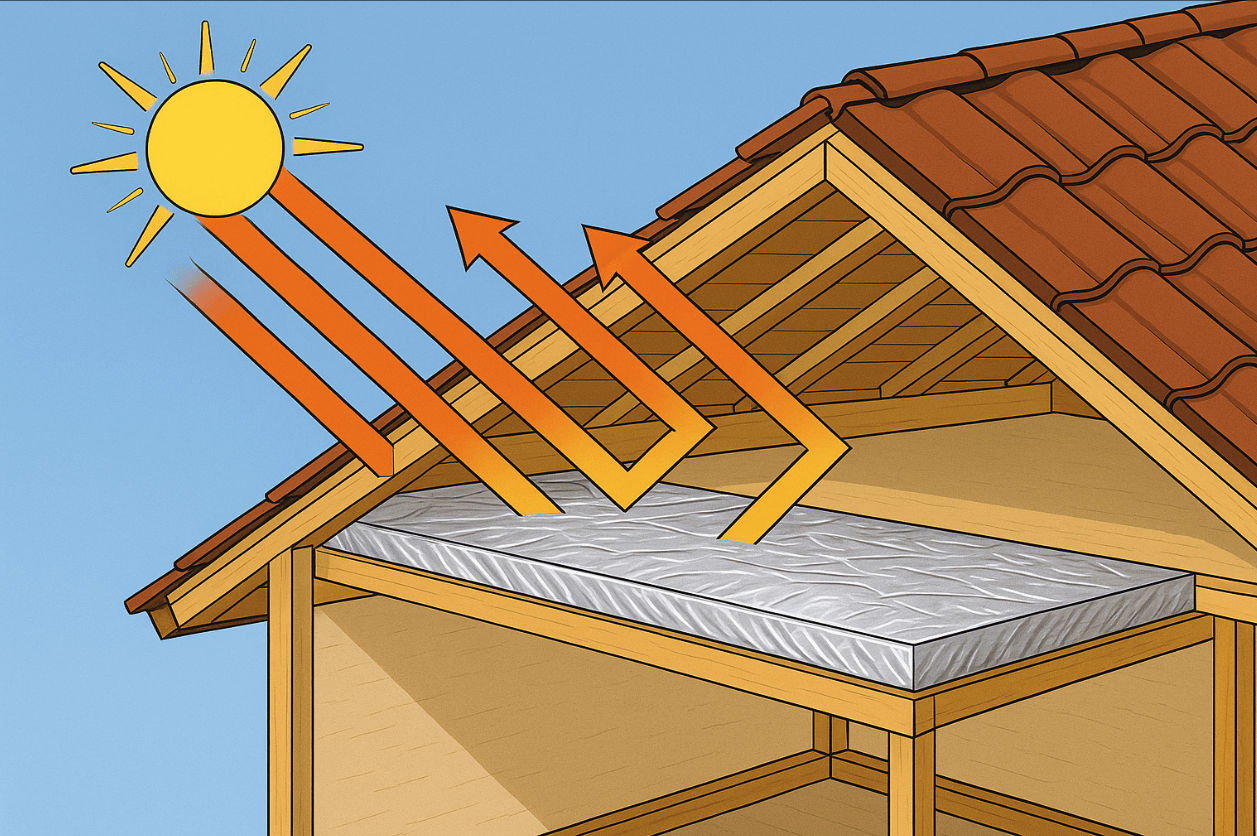

Radiant‑Barrier Physics vs. Conductive/Convective Insulation

Fiberglass and rock wool slow conduction and convection. By contrast, radiant barriers bounce infrared energy back toward its source. The U.S. Department of Energy notes that a properly installed radiant barrier can reflect up to 97 % of radiant heat—an advantage most bulk materials simply cannot match.

Typical Applications in Farming, Greenhouses, Attics, and Warehouses

After five seasons installing foil membranes in metal‑roof livestock barns, I’ve seen interior summer temperatures drop 8‑12 °F almost immediately after retrofit. Vegetable greenhouse operators report gentler night‑time temperature swings, leading to more consistent yields and lower heater runtimes.

7 Proven Benefits of Reflective Aluminum Foil Insulation

1. Cuts Summer Heat Gain by up to 97 %

Polished aluminum reflects incident solar radiation before it can turn into trapped hot air, keeping roof decks up to 30 °F cooler according to Florida Solar Energy Center testing.

2. Lowers Winter Heat Loss for Year‑Round Comfort

When heaters cycle on, the barrier sends infrared energy back into the room instead of letting it leak through rafters—a simple way to stretch BTUs on cold January nights.

3. Reduces HVAC Energy Bills 10‑20 %

An anonymized case study of a 45,000 ft² seed‑storage warehouse showed electricity savings of 18 % in the first billing cycle post‑install, verified through utility data.

4. Lightweight, Flexible, and Quick to Install—Save Labor Hours

At roughly 7 oz / yd², a single technician can lift and staple rolls overhead. Crews often finish 1,500 ft² per hour, half the time required for rigid panels.

5. Moisture & Mold Resistance Protects Stock and Crops

Aluminum is non‑hygroscopic and forms a natural oxide layer, so condensation wipes away without feeding mildew spores—critical for hay lofts and produce coolers.

6. Eco‑Friendly: Recyclable Aluminum and Non‑Toxic Core

Unlike spray foam, foil emits no isocyanates during installation. End‑of‑life panels can be bailed with scrap aluminum for full material recovery.

7. Works Seamlessly with Other Insulation Types for Higher R‑Values

Installers often combine foil under‑roof with fiberglass batts in wall cavities to achieve whole‑building R‑30 performance at a lower cost per square foot.

Selecting the Right Product for Your Project

Key Performance Metrics: Emissivity, Reflectivity, Thickness, Fire Rating

Aim for emissivity ≤ 0.05 and ASTM E84 Class A flame spread. Thicker two‑side foil with bubble core resists crush damage on job sites.

Matching Grades to Use Cases

Attic retrofits thrive on single‑layer foil stapled to rafters. Metal building roofs need perforated, double‑bubble sheets that breathe. Livestock barns benefit from white‑face foil on the interior to soften glare.

Questions to Ask Suppliers When Buying in Bulk

-

What is the minimum order for 4‑ft‑wide rolls?

-

Can you provide emissivity certificates?

-

Do you stock compatible foil tape?

Wellco Wholesale answers these queries daily and ships mixed‑product pallets to keep purchasing streamlined.

Installation Best Practices and Common Pitfalls

Surface Prep and Required Air Gap

Leave at least ¾ inch of air space on the reflective side; direct contact with sheathing can slash performance by as much as 50 %.

Step‑by‑Step Installation Checklist

-

Measure bays; cut rolls 2 inches longer.

-

Staple edges every 12 inches along framing.

-

Tape seams with UL 181 aluminum tape.

-

Seal penetrations around vents and purlins.

Safety Tips and Building‑Code Compliance

Wear cut‑resistant gloves—aluminum edges are sharp. Many jurisdictions reference International Residential Code R316; verify fire ratings before the building inspector arrives.

Maintenance, Durability, and Lifecycle Cost

Cleaning & Annual Inspection Guidelines

Vacuum dust with a soft brush each spring; even a thin grime layer can reduce reflectivity by 5‑7 %.

Service Life Expectations and Warranty Benchmarks

Quality foil carries 10‑year material warranties; real‑world service life commonly exceeds 25 years in dry conditions.

Payback Period vs. Fiberglass Batt and Spray Foam

A quick rule of thumb: divide installed cost (USD / ft²) by projected annual energy savings. Foil’s typical payback lands between 2.5‑4 years, outperforming spray foam in many light‑commercial builds.

Conclusion

Reflective aluminum foil insulation offers seven big wins—lower heat gain, stronger winter retention, leaner energy bills, fast installs, moisture protection, eco‑friendliness, and compatibility with existing insulation—making it a smart upgrade for barns, warehouses, and homes alike. For bulk rolls, matching foil tape, or technical datasheets, reach out to Wellco Wholesale today and start cutting energy costs on your next project.

Frequently Asked Questions

Q1. Does foil insulation replace traditional batts?

It acts on radiant heat, so pairing it with batts or spray foam often delivers the best total R‑value at a reasonable price.

Q2. Can I install reflective aluminum foil insulation under a metal roof?

Yes—ensure a vented air gap beneath the metal panels and use a perforated product to allow moisture to escape.

Q3. How does reflective foil hold up in humid greenhouses?

Aluminum resists vapor absorption; periodic wiping prevents mineral film that could dull reflectivity.

Q4. What is the lead time for 1,000 m² bulk orders?

Most wholesalers ship within 3‑5 business days; Wellco Wholesale maintains stock in key widths for faster turnaround.

Q5. Is special tape necessary?

Use acrylic‑based aluminum tape rated for −20 °F to 250 °F; generic cloth duct tape will lose adhesion.