Reflective Foil Wall Insulation: A Buyer’s Quick Guide

Energy bills and comfort complaints often trace back to underperforming walls. Reflective foil wall insulation—a radiant-control layer—reduces radiant heat transfer when it faces an adjacent air space, complementing the conductive resistance you get from batts or foam. Used in the right place (sun-loaded walls, hot/mixed climates), it can trim peak loads and even out room temperatures with minimal thickness.

Supplier context: Wellco Wholesale supports trade buyers and serious DIYers with bulk foil rolls, matched tapes, furring, and custom widths/lengths—useful if you’re kitting multiple job sites without waste.

About the author & review

Author: Building-Science Specialist (residential/light commercial envelopes)

Peer review: Licensed General Contractor (wall assemblies & exterior cladding)

Last updated: September 18, 2025

What It Is & How It Works

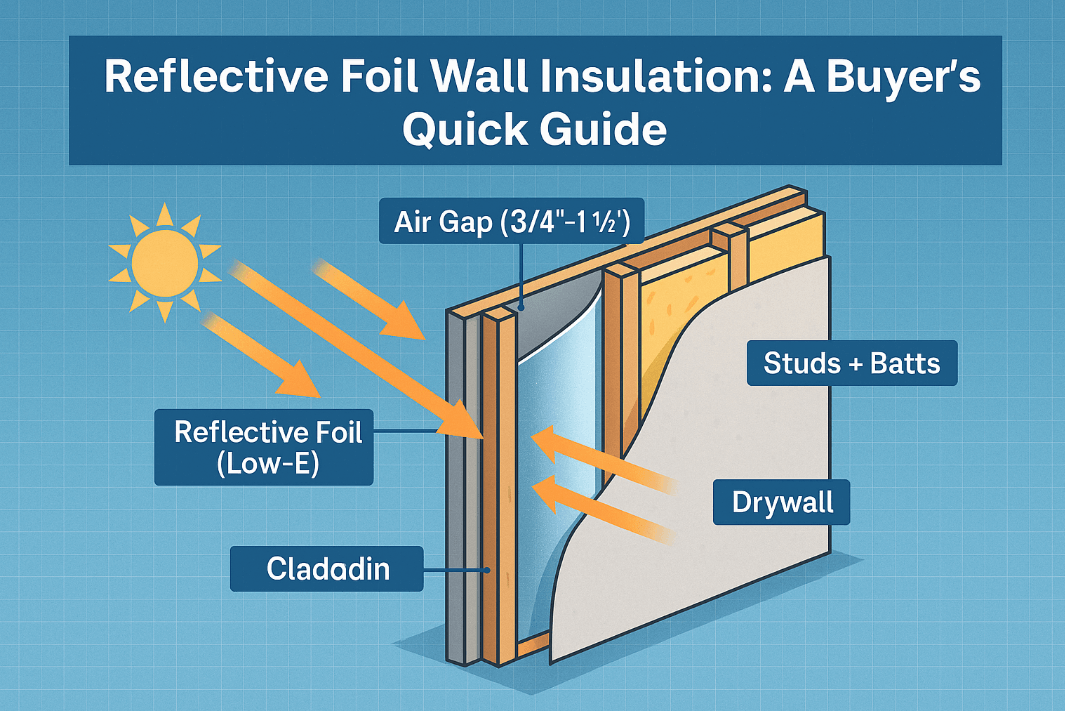

Low-emittance (low-e) foil reflects most long-wave radiant energy. When it faces a real air gap, the assembly gains R-equivalent resistance—especially under high delta-T. Products include single/double-sided aluminum bonded to bubble film, closed-cell foam, or scrim-reinforced cores. Perforated versions are vapor-open; non-perforated act as vapor retarders.

Standards & terms (for spec sheets):

Emissivity per ASTM C1371/C1376; surface burning classification per ASTM E84; vapor transmission per ASTM E96. Note that radiant barriers are rated by emittance and assembly R-equivalent (defined with the air-space size and orientation), not by standalone batt-style R-value.

Where It Shines (and Where It Doesn’t)

-

Best fit: Hot or mixed climates, west/south façades, garages/workshops, metal-clad buildings, bonus rooms over garages, small retail fit-outs, container/tiny homes with limited cavity depth.

-

Less impact: Fully shaded walls, very cold-dominant climates with minimal cooling loads, or any assembly where the foil touches another surface (no air gap).

Quick climate guide (typical intent):

| IECC Zone | Use case for foil in walls | Notes |

|---|---|---|

| 1–2 (Hot) | Strong candidate | Pair with batts/foam; face gap toward exterior heat source |

| 3–4 (Mixed) | Good when sun-loaded | Prefer ventilated rainscreen or interior service cavity |

| 5 (Cool) | Situational | Smaller energy impact; focus on airtightness & R-value |

| 6–8 (Cold) | Limited | Use primarily in attics/roofs; walls see modest benefit |

Performance Specs Buyers Should Check

-

Thermal metrics: Target emissivity ≤ 0.10 on the reflective face; verify published assembly R-equivalents with stated air-gap size and orientation. Performance drops with dusting, surface contact, or reversed facings.

-

Assembly details that drive results: Maintain a continuous ¾–1½ in (19–38 mm) air space on the reflective side. Cooling-dominant: reflective face toward the exterior heat source; heating-dominant: toward the interior. Tape and seal all seams/edges.

-

Compliance & durability: Confirm ASTM E84 class, perforation type (drying potential), tensile/tear strength, and compatibility with treated lumber, masonry, and dissimilar metals.

-

Sizing & logistics: Roll width/length, weight per roll, approved foil tape and furring SKUs, and fastener patterns.

Installation Methods (Step-by-Step)

Interior service cavity (new build or major reno)

-

Staple foil across studs with the shiny face toward the cavity air space.

-

Tape seams; seal penetrations.

-

Add ¾ in furring to preserve a service cavity; install gypsum board.

Exterior behind cladding (rainscreen approach)

-

Install/tape the WRB as required.

-

Apply foil; add vertical battens to create a ventilated cavity.

-

Integrate flashing/drainage; mount cladding over counter-battens.

Light retrofits (garages, sheds, workshops)

Add interior foil and furring to maintain the gap. Contact installs are quick but deliver smaller gains.

Common mistakes to avoid: Eliminating the air gap, mixing perforated/non-perforated randomly, wrong facing orientation, unsealed seams, trapping moisture, and skipping required thermal barriers.

Moisture, Vapor & Indoor Air

-

Vapor strategy by climate: Use perforated foil when the wall needs drying potential; use non-perforated when intentionally adding a vapor retarder in the correct location. Avoid double vapor barriers.

-

Condensation control: Air-seal first. Vent cavities where appropriate, terminate edges to limit convective looping, and maintain air-barrier continuity at floor lines.

-

Health & safety: Favor low-VOC tapes/adhesives; manage glare; protect hands on foil edges.

Code & Safety (Put in One Place)

-

Where foil is left exposed, many jurisdictions require a thermal barrier (e.g., ½" gypsum).

-

Maintain clearance from electrical boxes, recessed lights, and flues per manufacturer code notes.

-

Verify ASTM E84 flame/smoke class for the intended exposure.

-

Check corrosion notes when contacting treated lumber or concrete; use approved fasteners and tapes.

-

Always consult local building code/IECC and the product’s installation instructions.

Cost, Savings & a Mini Payback Example

-

Costs: Materials are typically competitive for thin-profile upgrades; open-wall installs are fast; retrofits add time for furring/detailing.

-

What drives savings: Climate, solar exposure, airtightness, air-gap quality, and whether you pair foil with mass insulation and shading.

Back-of-napkin example (illustrative):

Inputs → 400 ft² sun-loaded wall, $0.16/kWh electricity, minisplit draws ~1.2 kW during peak, reflective foil wall insulation reduces peak runtime ~10% on hot afternoons (assumes correct air gap + good air sealing).

Math → 1.2 kW × 3 h/day × 90 hot days × 10% ≈ 32 kWh/season (~$5). Expand across multiple walls/rooms and whole-house hours to gauge total impact. Pairing with air sealing and shading usually improves payback.

Estimator tip: Use your utility rate, square footage, and local cooling hours; combine upgrades (air sealing + foil + shading) for compound benefits.

Reflective Foil vs Fiberglass vs Foam (At a Glance)

| Category | Reflective Foil | Fiberglass/Cellulose | Foam Board/Spray |

|---|---|---|---|

| Main mechanism | Radiant control (needs air gap) | Conduction/convection resistance | High conduction resistance; potential air/vapor control |

| Typical role | Comfort/peak-load trim | Code-required R-value | Boost R-value, control air/vapor |

| Where it excels | Sun-loaded walls, thin build-ups | General cavity fills | Exterior continuous insulation, thermal bridges |

| Notes | Keep face clean; protect gap | Needs airtightness layer | Check fire/smoke, sealing, cost |

Takeaway: Hybrid assemblies—batts/foam for R-value + reflective foil wall insulation for radiant control—often deliver the best comfort per dollar on sun-exposed walls.

Procurement Guide for Pros & Bulk Buyers

-

Spec checklist (submittals): emissivity (≤0.10), perforation type, core/substrate, face protection, roll size, ASTM E84 class, approved tape/fastener systems, air-gap requirement and orientation for the published assembly R-equivalent.

-

Buying logistics: MOQs, lead times, pallet counts, export packaging, and job-site kitting (pre-cut widths + tape SKUs).

-

Sourcing help: Wellco Wholesale provides tiered bulk pricing, custom cuts, accessory kits, and sample rolls for crew training. Ask for stamped submittals and datasheets to smooth inspections.

Jobsite Vignette (Experience)

On a mixed-climate retrofit, we measured stud bows and shimmed furring to a consistent 1 in gap behind drywall. We chose perforated foil to preserve drying to the interior and taped every seam before board-up. The inspector appreciated the explicit submittal page listing emissivity, E84 class, and the air-gap requirement; the crew’s punch-list shrank to touch-ups instead of rework.

Frequently Asked Questions

Can reflective foil replace my batts?

No. Keep or add mass insulation to meet code R-values; foil augments comfort and peak-load control.

Which way should the shiny side face?

Toward the air space and dominant heat source. Without a gap, orientation matters far less.

Is foil allowed as the only interior finish?

Often no—many jurisdictions require a thermal barrier (e.g., gypsum). Check your code and the product listing.

How do I handle outlets and penetrations?

Cut tight, seal edges with approved foil tape, and maintain the air gap around boxes using spacers or shallow furring details.

What if I can’t maintain a full ¾ in gap?

Smaller gaps reduce benefit, but consistent spacing still helps. Prioritize continuity and sealing over a nominal dimension.

Will reflective foil help with sound?

Minimal. Use batt density, decoupling, and airtightness for acoustic goals.

Conclusion

When you protect the air gap and plan a vapor strategy, reflective foil wall insulation is a smart, thin-profile add to sun-loaded walls—best as part of a hybrid assembly with airtightness and code-compliant R-value. If you’re speccing multiple sites, Wellco Wholesale can kit rolls, tapes, and furring to your method and ship directly to the job.