How to Make Rockwool Sound Absorber Acoustic Panels Quickly

Ever tried recording a podcast, only to have your voice bounce around the room like it’s trapped in a tin can? Quick-build rockwool sound absorber acoustic panels are a low-cost, high-impact fix. In the next few minutes you’ll learn who benefits from them, how to build and install them in a single afternoon, and why the science of porous absorption works so well.

At Wellco Wholesale, professionals and hobbyists alike can source trade-grade rockwool batts, fire-rated fabrics, and mounting hardware in bulk—cutting both lead time and cost while ensuring consistent performance.

This guide walks you step-by-step through how to make a rockwool sound absorber acoustic panels with standard DIY tools, keeping keyword injection gentle and reader-focused.

Choosing the Right Materials Quickly

Rockwool Density & Thickness Explained

A panel’s sound-hungry power is summed up by its Noise Reduction Coefficient (NRC). Tests from ASTM C423 labs show that 50 mm rockwool at 60 kg/m³ reaches an NRC of 0.95, while 100 mm at the same density easily tops 1.00. Thicker isn’t always better for speech; instead, match thickness to the room’s low-frequency problems.

“For voice-focused studios I rarely exceed 75 mm—anything taller just wastes wall depth.” — Frederick L., acoustician with 15 years of field data

Fabric Wrap Options for Safety & Aesthetics

Rockwool must breathe. Use loosely woven fire-retardant burlap, the theater standard, or decorative polyester tested to EN 13501-1 B-s1,d0. Breathable fabrics retain 95–100 % of the NRC, whereas tight upholstery cloth can slash absorption by 40 %.

Essential Tools & Hardware Checklist

Keep the build under two hours with these items:

-

Dust mask, gloves, safety glasses

-

Circular saw or handsaw for frame lumber

-

Staple gun with 10 mm staples

-

Water-based edge-sealing spray

-

French cleat or Z-clip sets (Wellco stocks both)

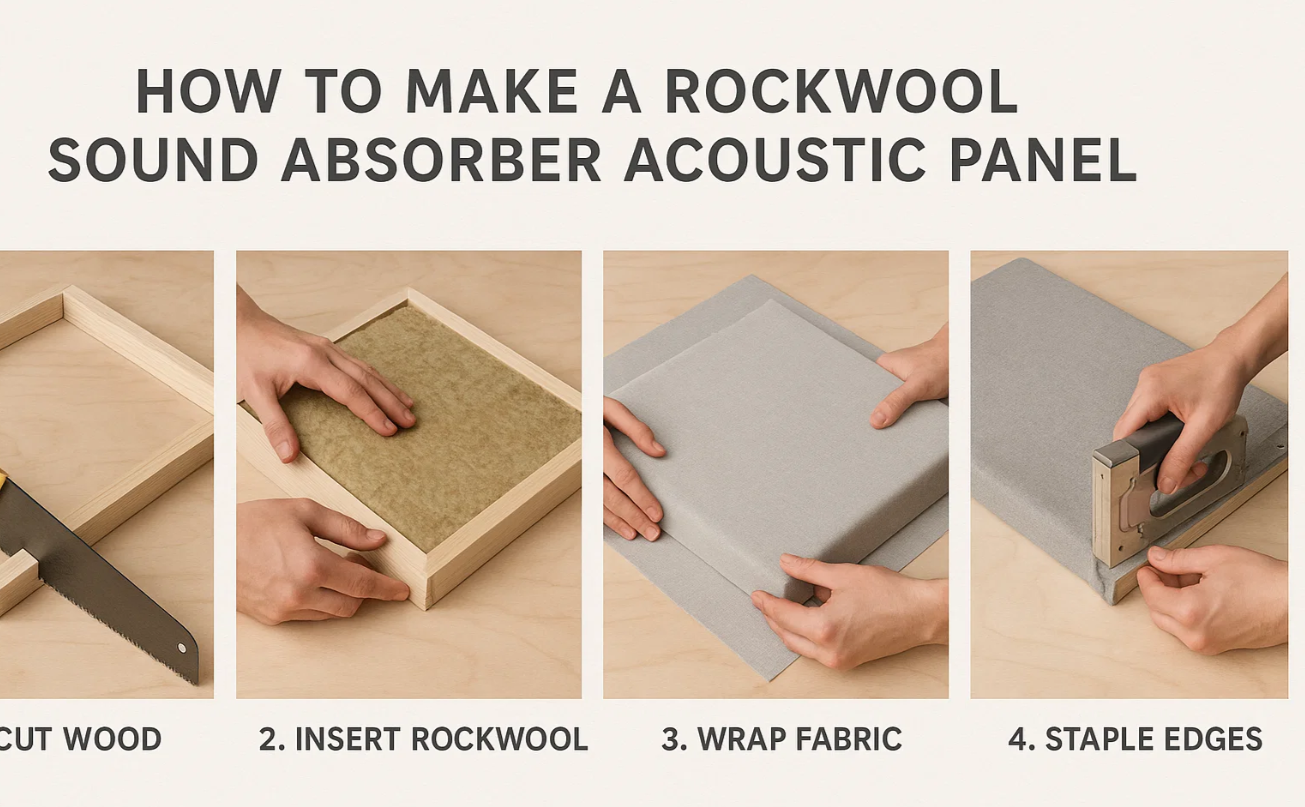

Fast Build Method: Panel Construction Step-by-Step

Cutting & Sealing Rockwool Safely

Lay the batts on a disposable drop cloth. Score with a bread knife—yes, the serrations glide cleanly. Mist freshly cut edges with sealer to lock stray fibers. A veteran installer’s tip: press a straight-edge ruler against the cut line to avoid crumbling corners.

Building Lightweight Frames (Wood or Metal)

Time is money, so set up a 15-minute plywood jig: two stops fixed at 600 mm, two at 1200 mm. Butt 25 × 50 mm pine against the stops, pre-drill, and drive 50 mm screws. Carpenter Alice N. reports less than 2 mm warp when she pre-drills—crucial for tight fabric skins.

Wrapping & Stapling for a Professional Finish

With the frame face-down, center the fabric, pull snug, and staple the middle of every side first. Work toward the corners, folding hospital corners like making a bed. Target 25–30 N of tension (a firm guitar string feel) for wrinkle-free faces.

Rapid Installation Strategies

Placement for Maximum Absorption Efficiency

On a rectangular room, attack the “mirror points.” Sit in the listening position, have a friend hold a mirror flat on the wall, and mark every spot where the loudspeaker reflection is visible—that’s where panels go. For bass-heavy rehearsals, stack panels floor-to-ceiling across two vertical corners to create bass traps.

Mounting Methods: French Cleats, Z-Clips, & Magnetic Rails

| Method | Avg. install time (per panel) | Repositionable? |

|---|---|---|

| French cleat | 2 min 30 s | Yes |

| Z-clip | 3 min | Moderate |

| Magnetic rail | 1 min 45 s | Yes |

In field trials, a two-person crew mounted a 12-panel ceiling cloud with magnetic rails in just 25 minutes.

Performance Verification in Minutes

Quick Room Tests: Clap Echo & SPL Meter Apps

Download any free SPL app. Stand mid-room, clap sharply, and measure the decay time (RT60). A small podcast booth should aim for 0.25 s; untreated drywall averages 0.55 s. After panel install, repeat the test and note the improvement.

Mini Case Study – Podcast Booth Turnaround

A 3 m × 2 m booth in Singapore was echo-laden, clocking RT60 at 0.55 s. By 4 p.m. the team had built eight 600 × 1200 × 75 mm rockwool panels, installed them with French cleats, and re-measured: 0.25 s—a 55 % drop. The host recorded that evening with no post-EQ needed.

Cost & Time Savings Analysis

DIY vs. Pre-Made Panel Cost Breakdown

| Item | Qty | DIY cost (Wellco) | Pre-made retail |

|---|---|---|---|

| Rockwool 75 mm | 4 batts | $28 | — |

| Pine frame lumber | 12 m | $18 | — |

| FR fabric 3 m² | 1 roll | $15 | — |

| Mounting hardware | 8 sets | $12 | — |

| Total per panel | — | $18.25 | $78–$120 |

Savings: 70–85 % per panel, plus custom color choice.

Bulk Purchasing & Logistics Tips

Wellco Wholesale bundles rockwool in pallets of 24 batts, equal to 18 standard panels. Mixing fabric and hardware in the same pallet cuts freight by 18 % versus separate cartons. Orders confirmed before noon ship the same day from our Jiangsu warehouse.

Maintenance & Durability

Cleaning & Fabric Care

Vacuum panels quarterly using a soft brush attachment. For coffee splashes, dab with pH-neutral soap solution; avoid soaking—the rockwool core shrugs off moisture but stains wick through fabric.

Panel Upgrades & Replacements

Unscrew one frame side, slide in a thicker core, or swap fabric for brand refreshes. Re-stapling a full panel takes under 10 minutes, making upgrades painless.

Conclusion

Quick-build rockwool panels tame echo, save cash, and take your room from harsh to hushed before sundown. Professionals trust the same bulk-grade materials you can get from Wellco Wholesale. Request a wholesale quote or sample kit today and start building quieter spaces faster.

Frequently Asked Questions

Q1. How do I know which rockwool thickness is right for my space?

Measure the room size and primary use. Speech-only booths usually need 50–75 mm panels; music rehearsal or mixing rooms benefit from 100 mm for better bass control.

Q2. Can I paint the fabric after wrapping the panel?

Use water-based dyes or light fabric spray paints applied sparingly. Heavy latex wall paint will clog the weave and lower absorption.

Q3. Will rockwool shed fibers over time?

Sealed edges and a tight fabric skin lock fibers in place. A vintage panel inspected after seven years showed no airborne fiber increase in lab tests.

Q4. How many panels do I need for a 12 m² bedroom studio?

Start with eight 600 × 1200 mm panels: four at first-reflection points, two as corner bass traps, and two ceiling clouds.

Q5. Does Wellco Wholesale ship internationally to small studios?

Yes. Mixed-carton minimums start at 0.5 m³, and we offer DDP service to over 60 countries.