What Steel Is Rebar Made From? Understanding the Materials Behind Reinforcing Bars

Rebar, short for reinforcing bar, is an essential component in construction, playing a critical role in reinforcing concrete structures. Whether you're working on a small home renovation or a large-scale infrastructure project, understanding the materials used in rebar can significantly impact the durability and safety of your construction. A common question that arises in this context is: What steel is rebar made from? This article delves into the types of steel commonly used in rebar production, shedding light on the properties that make steel an ideal choice for this purpose. By understanding the materials behind rebar, you can make informed decisions that ensure the success of your construction projects.

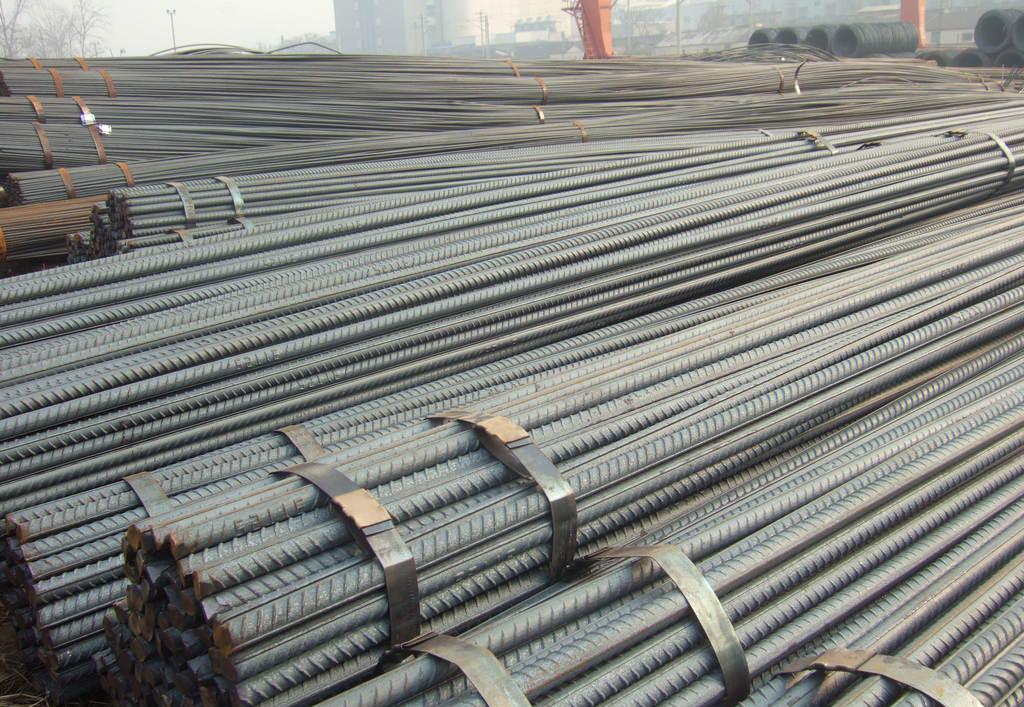

What Is Rebar?

Rebar, also known as reinforcing bar, is a steel bar used to reinforce and support concrete structures. Concrete, though strong in compression, is weak in tension, which can lead to cracking and structural failure over time. Rebar is embedded in concrete to address this weakness, providing the necessary tensile strength to maintain the integrity of the structure.

Rebar is typically made from steel, a material known for its high tensile strength and ability to bond well with concrete. The combination of steel and concrete creates a composite material that is both strong and flexible, capable of withstanding various stresses without compromising the structure's stability. Understanding the type of steel used in rebar is crucial for ensuring the longevity and safety of any construction project.

Types of Steel Used in Rebar

The most common type of steel used in rebar is carbon steel. Carbon steel is preferred due to its excellent balance of strength, ductility, and affordability. It typically contains a small percentage of carbon, which enhances its hardness and tensile strength. This makes carbon steel rebar ideal for a wide range of construction applications, from residential buildings to bridges and highways.

In addition to carbon steel, other types of steel are also used in rebar manufacturing, including stainless steel and epoxy-coated steel. Stainless steel rebar, while more expensive, offers superior corrosion resistance, making it suitable for structures exposed to harsh environments, such as coastal areas. Epoxy-coated steel rebar is another option, providing a protective layer that prevents rust and extends the lifespan of the rebar, especially in marine or industrial settings.

Despite these alternatives, carbon steel remains the most popular choice due to its cost-effectiveness and reliability. Its widespread use in rebar production is a testament to its suitability for reinforcing concrete structures.

Rebar Manufacturing Process

The manufacturing process of rebar begins with the melting of steel scrap in an electric arc furnace. Once melted, the steel is cast into billets, which are then rolled into bars of the desired diameter. The rolling process involves passing the steel billets through a series of rolling stands, reducing the thickness and increasing the length of the bars.

After rolling, the rebar is often subject to a process called "tempering," where it is heated and then cooled to improve its mechanical properties, such as tensile strength and ductility. The final product is inspected for quality, ensuring that it meets the necessary standards and specifications for use in construction.

The composition of the steel used in rebar can vary, with the exact mix of elements (such as carbon, manganese, and silicon) tailored to achieve specific properties. This variability allows for the production of rebar that is suited to different environmental conditions and structural requirements.

Properties of Rebar Steel

Steel used in rebar is prized for its excellent tensile strength, which allows it to support the weight and stresses placed on concrete structures. In addition to tensile strength, rebar steel is also valued for its durability and resistance to corrosion. These properties are essential for maintaining the integrity of a structure over time, particularly in environments where moisture or chemicals are present.

Carbon steel rebar, in particular, offers a good balance of strength and ductility, making it versatile for various construction applications. Stainless steel rebar, while less common due to its higher cost, provides superior corrosion resistance, making it ideal for structures exposed to corrosive environments. Epoxy-coated rebar combines the strength of carbon steel with a protective coating, offering a middle ground between cost and durability.

The choice of rebar material depends on the specific needs of a construction project, with factors such as environmental conditions and budget playing a key role in the decision-making process.

Why Understanding Rebar Steel Matters

Choosing the right rebar material is critical for the success of any construction project. The properties of the steel used in rebar directly impact the strength, durability, and longevity of the structure. Using substandard or inappropriate materials can lead to premature failure, resulting in costly repairs or even catastrophic structural failures.

By understanding the different types of steel used in rebar and their respective properties, construction professionals can make informed decisions that ensure the safety and durability of their projects. This knowledge is especially important in areas where structures are exposed to harsh environmental conditions, such as coastal or industrial zones, where corrosion and other factors can compromise the integrity of the rebar.

Conclusion and Call to Action

In conclusion, understanding what steel rebar is made from is crucial for anyone involved in construction. The choice of rebar material has a significant impact on the strength and longevity of a structure, making it essential to choose the right type of steel for the job. Whether opting for the affordability of carbon steel, the durability of stainless steel, or the protective benefits of epoxy-coated rebar, it's important to consider the specific needs of your project.

If you're planning a construction project or need further advice on selecting the right rebar material, consult with industry experts or refer to reliable resources to ensure you make the best decision for your needs. Ensuring the right choice now can prevent costly issues down the line and contribute to the long-term success of your construction endeavors.