How Does Reflective Foil Insulation Work? 5 Key Facts

Tom, a third‑generation greenhouse grower in Fresno, was spending more on summer cooling than on seeds. After wrapping his roof in reflective foil insulation, the interior temperature dropped 8 °C within a week, saving him hundreds of dollars in electricity. Stories like Tom’s remind us that understanding how does reflective foil insulation work isn’t academic—it’s money in the bank and comfort in the workspace.

Reflective foil insulation is a thin, multi‑layer radiant barrier—usually aluminum bonded to polyethylene bubbles or foam—that reflects heat rather than absorbing it. Whether you run a metal shed, an urban attic, or a commercial greenhouse, knowing the principles behind the material helps you choose, install, and maintain it for maximum payoff. Wellco Wholesale, a factory‑direct supplier to trade professionals, stocks bulk rolls and accessories for projects just like Tom’s.

What Is Reflective Foil Insulation & Who Uses It?

How It Differs From Fiberglass, Foam, and Mineral Wool

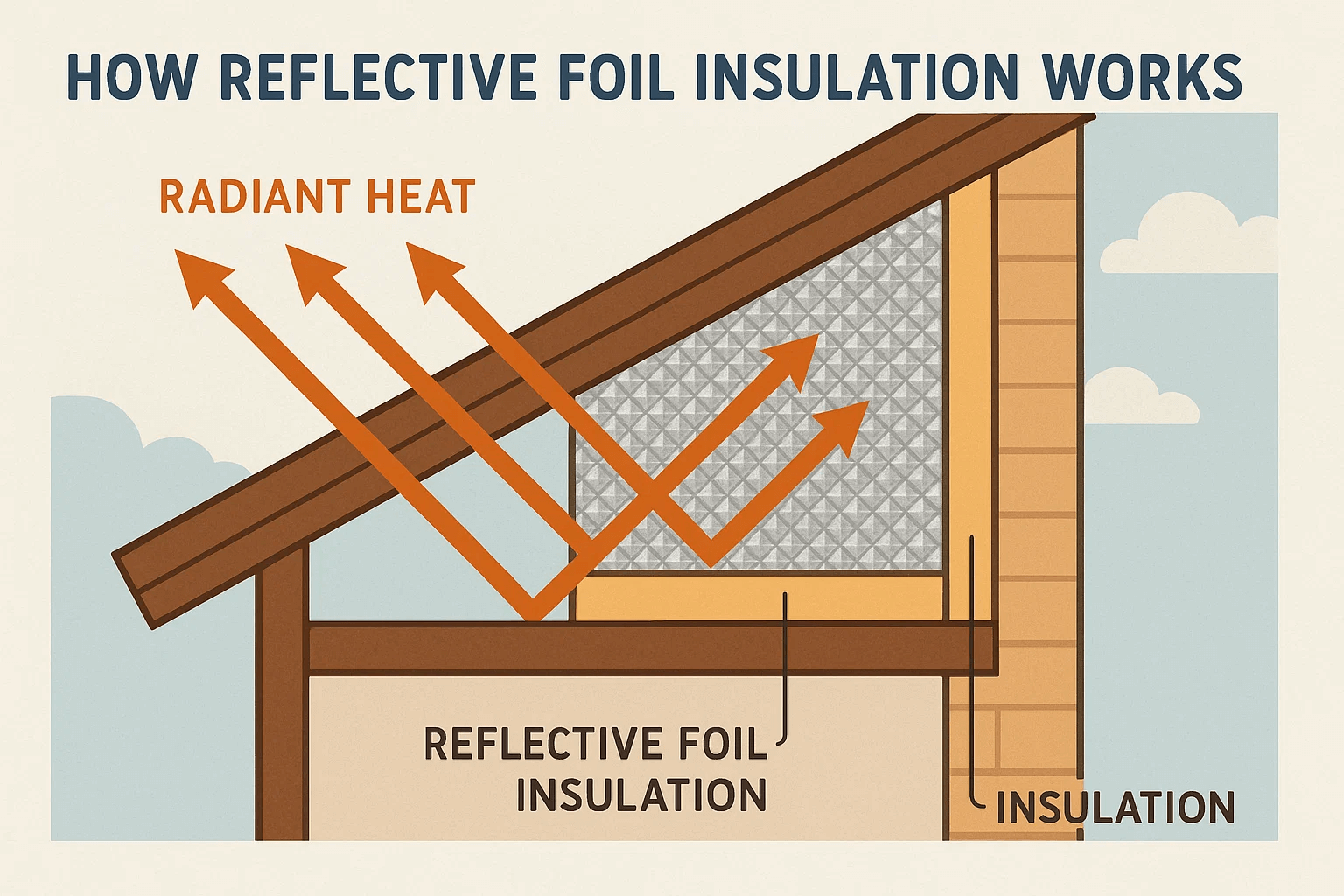

Traditional batts slow heat transfer mainly by conduction. Reflective foil attacks radiant heat, bouncing up to 97 % of energy back toward its source (ASTM C1371). That makes it perfect for spaces where sunlight or machinery radiates intense heat.

Core Users: Agriculture, Light‑Industrial Warehouses, Attics & Sheds

-

Greenhouses & barns—protect crops and livestock from heat stress.

-

Distribution centers—cut HVAC costs in vast, open bays.

-

Residential DIYers—staple barrier under rafters for fast attic upgrades.

“Radiant barriers reduced ceiling heat‑flux by an average of 40 % in our test sheds,” notes Dr. Elena Ruiz, Building Physics Lab, Cal State Polytechnic.

In a 2023 meta‑analysis of 24 field studies, average cooling‑load reduction ranged 10 – 22 % when radiant barriers supplemented conventional insulation.

How Does Reflective Foil Insulation Work? (The Science, Simplified)

Radiant Heat Transfer 101 – Conduction vs. Convection vs. Radiation

Heat moves three ways. Conduction passes through solids; convection rides air currents; radiation travels in electromagnetic waves. Aluminum’s low emissivity (≤ 0.05) means it emits very little radiant energy, so instead of absorbing solar heat, it hurls it back outward.

Low‑Emissivity Surfaces + Trapped Air Gaps = Thermal Break

A foil sheet alone is not magic; it needs a ¾‑inch air gap on the shiny side. The still air adds resistance and lets the surface reflect radiation efficiently.

Mini Case Study

A 5,000 sq ft tomato greenhouse in Yuma, Arizona added double‑sided foil between the polycarbonate roof and shade cloth. Power company smart‑meter data showed a 15 % drop in kWh consumption from May through August, trimming the payback period to just 14 months.

Choosing the Right Product for Your Project

Key Specs: Emissivity, Reflectivity, Perforation, Reinforcement Mesh

-

Reflectivity ≥ 0.90 for hot climates; slightly lower is acceptable where winter heating dominates.

-

Single vs. double bubble—double insulates sound better and resists crushing.

-

Perforated rolls allow vapor to escape in humid zones.

-

Tri‑directional fiberglass mesh boosts tear strength for metal buildings.

Compliance & Testing Standards Buyers Should Check

-

ASTM C1224 (temperature resistance)

-

ISO 9001 (manufacturing quality)

-

FM 4880 (fire performance)

Value‑Add from Wellco Wholesale

Wellco screens suppliers on these standards and bundles bulk‑buy SKUs (up to 500 m² per pallet) so contractors skip multiple middlemen and stay on schedule.

“The pre‑cut 4‑ft rolls saved my crew a full day on site,” says Alex Chung, HVAC installer, Seattle.

Installation Best Practices for Maximum Performance

Prep & Safety: Clean, Dry, Dust‑Free Surfaces; PPE Essentials

-

Wear cut‑resistant gloves; foil edges are razor‑sharp.

-

Work on dry days to keep moisture out of enclosed layers.

Creating and Maintaining the Critical Air Space

-

Furring strips or thermal break tape ensure a uniform cavity.

-

For roofs steeper than 45°, add extra staples every 12 inches to stop sagging.

Common Mistakes—and How to Avoid Them

| Error | Impact | Fix |

|---|---|---|

| Foil facing wrong way | Reflects heat inward on hot days | Shiny side toward heat source |

| Gaps between seams | Routes hot air behind barrier | Overlap 2 in & seal with foil tape |

| Compression by drywall | Kills air gap | Use spacer battens |

Cost, ROI, and Sustainability Considerations

Material + Labor Cost Benchmarks vs. Traditional Insulation

| Application | Foil + Bubble | Fiberglass Batt |

|---|---|---|

| Greenhouse roof (m²) | $3.20 | $2.70 |

| Metal barn wall (m²) | $2.80 | $2.60 |

Labor is lower for foil—one worker can staple 50 m² h compared with 35 m² h for bulky batts.

Payback Period Snapshot

-

Residential attic (180 m²): 2–3 years

-

Metal barn (900 m²): 14–18 months

-

Greenhouse (5,000 m²): 12–16 months

Environmental Footprint

-

Aluminum layers are 100 % recyclable.

-

Low‑VOC adhesives meet EU REACH standards.

-

Thin profile (<10 mm) halves shipping emissions versus mineral wool of equivalent R‑value.

Maintenance & Longevity

Inspection Schedule

Perform a quick visual check every spring: look for dust accumulation, condensate streaks, or punctures near fasteners.

Cleaning & Simple Repairs

-

Vacuum dust with a soft brush attachment or wipe with isopropyl alcohol.

-

Patch pinholes using self‑adhesive foil tape rated to 80 °C.

Building engineer Carla Mendoza notes, “A radiant barrier can last 25 years if you keep it clean and sealed.”

Conclusion

Reflective foil insulation fights radiant heat with science‑backed efficiency, slashing cooling bills for growers, warehouse managers, and homeowners alike. Armed with the right specs, airtight installation, and routine maintenance, you can capture those savings for decades. For trade‑grade rolls, custom widths, and on‑the‑job expertise, request a quote from Wellco Wholesale today—and start turning heat into profit.

Frequently Asked Questions

Q1. Does reflective foil insulation replace traditional batts or work with them?

It complements them. Foil handles radiant heat, while batts or spray foam slow conductive and convective transfer, giving you a fuller thermal shield.

Q2. Can I staple the foil directly to roof decking without an air gap?

You’ll still get some benefit, but efficiency drops sharply. Always create at least a ¾‑inch cavity on the shiny side for best results.

Q3. Will the foil interfere with Wi‑Fi or cellular signals inside my building?

In most wood‑frame homes the effect is negligible. For steel structures, adding a few strategic signal repeaters restores full coverage.

Q4. How long does a roll keep its reflectivity?

Properly installed indoors, aluminum layers retain ≥ 90 % reflectivity for 20–25 years. Dusting annually prevents dulling.

Q5. What’s the lead time for bulk orders from Wellco Wholesale?

Standard pallet quantities ship within three business days, and custom widths typically add one week.