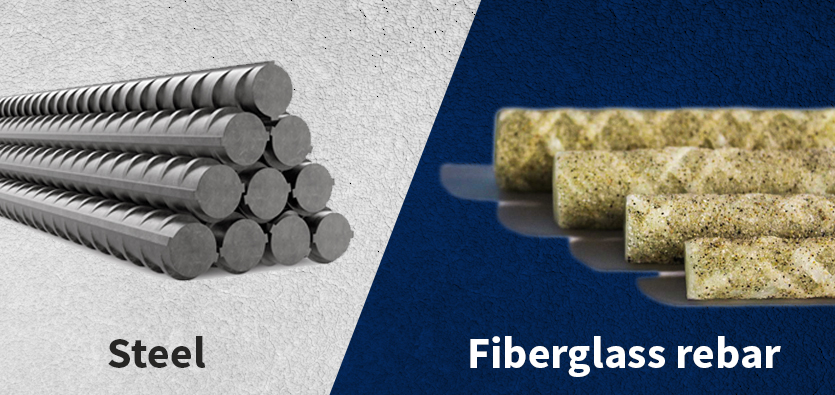

Understanding Fiberglass Rebar vs Steel Strength: Key Differences Explained

In the world of construction, choosing the right materials is crucial for ensuring the durability and longevity of any project. Rebar, short for reinforcing bar, plays a significant role in providing structural integrity, particularly in concrete applications. While steel has been the traditional choice for rebar, fiberglass rebar is gaining attention as a viable alternative. One of the key factors in selecting the appropriate rebar material is understanding its strength. This article will compare the strength of fiberglass rebar versus steel to help you make an informed decision.

What is Fiberglass Rebar?

Fiberglass rebar, also known as GFRP (Glass Fiber Reinforced Polymer) rebar, is a composite material made from high-strength glass fibers and a polymer resin. This type of rebar is designed to reinforce concrete structures, just like its steel counterpart. However, fiberglass rebar offers some unique advantages. It is lightweight, non-conductive, and highly resistant to corrosion, making it an attractive option for certain construction applications. Due to its unique properties, fiberglass rebar is often used in environments where steel rebar might fail or require significant maintenance over time.

What is Steel Rebar?

Steel rebar is a metal reinforcement bar that has been the industry standard for decades. Made primarily of carbon steel, this rebar is designed to provide additional tensile strength to concrete, which is inherently weak in tension. Steel rebar is known for its high tensile and compressive strength, which makes it suitable for a wide range of construction applications, from residential buildings to large-scale infrastructure projects. Its durability and familiarity make it a popular choice, especially in projects where initial cost and established engineering practices are significant considerations.

Comparing Strength: Fiberglass Rebar vs Steel

When comparing the strength of fiberglass rebar and steel, it's important to consider several mechanical properties, including tensile strength, load capacity, and elasticity.

-

Tensile Strength: Fiberglass rebar typically offers a higher tensile strength than steel. The tensile strength of fiberglass rebar can range from 89,900 to 159,500 psi, while standard steel rebar usually falls between 60,000 and 80,000 psi. This means that fiberglass rebar can handle higher stress without breaking, making it an excellent choice for applications where tensile strength is a critical factor.

-

Load Capacity: Steel rebar, however, tends to have a superior load-bearing capacity, especially in compression. Steel's density and ductility allow it to withstand heavy loads and resist deformation. While fiberglass rebar is strong, it is more brittle than steel, which can make it less ideal in situations where the material might experience significant bending or compressive forces.

-

Elasticity: Steel rebar is highly elastic and can bend without breaking, which is advantageous in seismic zones or structures subject to dynamic loads. Fiberglass rebar, on the other hand, does not bend as easily due to its brittle nature, which can be a limitation in some applications. However, in situations where minimal deformation is desired, fiberglass may offer better performance.

Factors Influencing Strength in Different Conditions

The strength of both fiberglass and steel rebar can be affected by various environmental factors:

-

Corrosion Resistance: One of the most significant advantages of fiberglass rebar over steel is its resistance to corrosion. Steel rebar is prone to rust when exposed to moisture, salts, and chemicals, which can weaken the concrete structure over time. In contrast, fiberglass rebar does not corrode, making it ideal for use in marine environments, bridges, and structures exposed to de-icing salts.

-

Temperature Resistance: Steel rebar can maintain its properties across a wide range of temperatures, but it may lose strength when exposed to extreme heat, such as in the case of a fire. Fiberglass rebar, while generally resistant to lower temperatures, can degrade under prolonged exposure to high temperatures. Special formulations of fiberglass rebar are available that offer improved fire resistance.

-

Chemical Resistance: Fiberglass rebar offers superior chemical resistance compared to steel, making it a preferred choice in structures exposed to harsh chemicals, such as wastewater treatment plants and industrial facilities.

Cost-Effectiveness and Long-Term Benefits

While the initial cost of fiberglass rebar is often higher than that of steel, it may offer cost savings in the long term due to reduced maintenance needs and a longer lifespan in corrosive environments. Steel rebar, although cheaper upfront, may require frequent inspections, maintenance, or even replacement due to corrosion and rust, particularly in environments exposed to moisture or chemicals.

For projects where durability and low maintenance are priorities, especially in harsh environments, fiberglass rebar can offer significant financial advantages over the long term.

Use Cases: When to Choose Fiberglass Over Steel?

Fiberglass rebar is particularly advantageous in the following scenarios:

- Marine Structures: In structures exposed to saltwater, such as docks, piers, and offshore platforms, fiberglass rebar's resistance to corrosion makes it a superior choice.

- Bridges and Tunnels: Fiberglass rebar is ideal for bridge decks, tunnel linings, and other applications exposed to de-icing salts and chemicals.

- Chemical Plants and Industrial Facilities: For construction in highly corrosive environments, such as chemical plants or wastewater treatment facilities, fiberglass rebar offers excellent chemical resistance.

- Electrical Insulation Requirements: In applications where non-conductive properties are essential, such as near electrical lines or in MRI facilities, fiberglass rebar is the preferred material.

Conclusion

Both fiberglass and steel rebar have their unique strengths and are suited to different applications. Fiberglass rebar offers superior tensile strength, corrosion resistance, and is ideal for environments where long-term durability is a concern. Steel rebar, on the other hand, provides excellent compressive strength, elasticity, and is often more cost-effective for projects with less exposure to harsh conditions.

When choosing between fiberglass and steel rebar, consider the specific needs of your project, including environmental factors, cost, and required strength properties. By understanding the key differences between these materials, you can make an informed decision that ensures the longevity and safety of your construction.