Fibreglass Rebar vs Steel: Comparing Strength, Durability, and Cost

In the world of construction, selecting the right materials is crucial for ensuring the longevity, safety, and cost-effectiveness of a project. Among these materials, rebar plays a critical role in reinforcing concrete structures, adding strength and stability. Traditionally, steel rebar has been the go-to choice, but in recent years, fibreglass rebar has emerged as a popular alternative. In this article, we will explore the differences between fibreglass rebar vs steel, focusing on their strength, durability, and cost. Understanding these factors can help you make an informed decision for your next construction project.

What is Rebar?

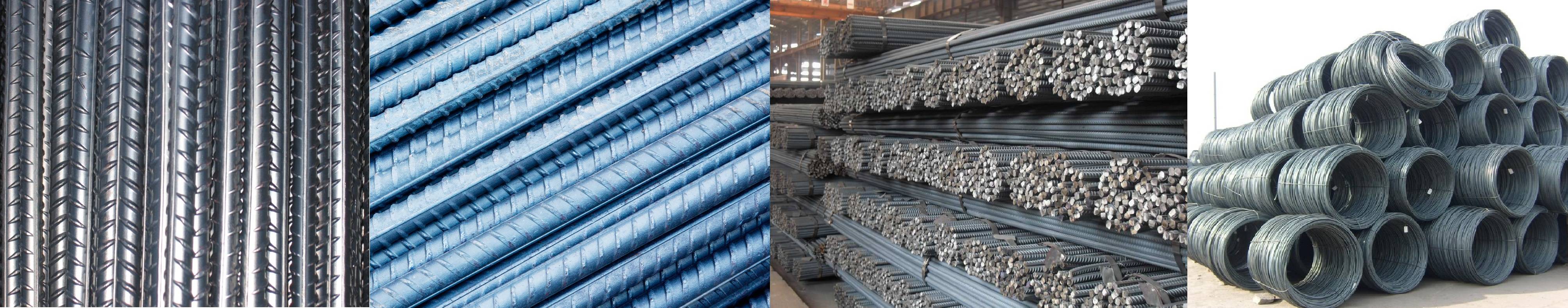

Rebar, short for reinforcing bar, is a material commonly used to strengthen concrete. While concrete is excellent at withstanding compression, it is weak when subjected to tension. Rebar provides the tensile strength needed to support structures under various loads, preventing cracking and structural failure.

Steel rebar has long been the standard, offering considerable strength and flexibility. However, fibreglass rebar, made from glass-fibre reinforced polymer (GFRP), has grown in popularity due to its lightweight nature and superior resistance to corrosion. Both materials have their strengths and limitations, which we will explore in detail.

Strength Comparison

When it comes to strength, both steel and fibreglass rebar have their unique advantages. Steel rebar is well-known for its high tensile strength, which typically ranges between 60,000 and 75,000 psi (pounds per square inch). Its ability to withstand heavy loads and its flexibility make it suitable for a wide range of construction projects, from residential buildings to large-scale infrastructure.

On the other hand, fibreglass rebar, while not as strong in terms of raw tensile strength, usually boasts a tensile strength of around 100,000 psi, higher than steel. Despite this, fibreglass rebar is less ductile, meaning it doesn't bend or deform before breaking, which can be a drawback in certain applications. However, fibreglass rebar is lighter than steel and easier to transport and handle on-site, making it a viable choice for projects that prioritize weight reduction.

For projects requiring extreme tensile strength and flexibility—like skyscrapers or large bridges—steel rebar is typically the preferred choice. However, for lighter applications or environments prone to corrosion, fibreglass rebar can outperform steel.

Durability and Corrosion Resistance

One of the most significant differences between steel and fibreglass rebar is how they handle exposure to environmental elements. Steel rebar is highly susceptible to rust and corrosion, especially in coastal, marine, or high-humidity environments. Over time, corrosion in steel can lead to weakened structural integrity, requiring costly repairs and replacements.

Fibreglass rebar, in contrast, is naturally resistant to corrosion. Since it is made of non-metallic materials, fibreglass rebar does not rust, even when exposed to water or chemicals. This makes it an excellent choice for marine structures, bridges, or areas with high exposure to saltwater or chemicals. In fact, fibreglass rebar can last several decades without any noticeable degradation, making it a more durable option in environments where corrosion is a concern.

However, steel rebar does have an edge in terms of impact resistance and overall toughness. In situations where a structure may face heavy physical stress, such as earthquakes or heavy traffic loads, steel's ability to bend before breaking makes it more reliable.

Cost Comparison

The cost of rebar can vary significantly depending on the project, location, and market conditions. Steel rebar is generally less expensive upfront, which is why it remains a popular choice for budget-conscious projects. On average, the cost of steel rebar ranges from $0.50 to $1.50 per linear foot.

Fibreglass rebar, however, tends to be more expensive upfront, with prices ranging from $1.50 to $2.50 per linear foot. The higher cost is primarily due to the specialized materials and manufacturing processes required to produce fibreglass rebar.

That said, the long-term cost-effectiveness of fibreglass rebar cannot be ignored. Because it is resistant to corrosion, it requires far less maintenance and replacement over time compared to steel rebar, which can rust and degrade. When factoring in the costs of potential repairs and replacements, fibreglass rebar may offer greater savings in the long run, particularly for projects in harsh environments.

Environmental Impact

Sustainability has become a key concern in modern construction, and the choice between steel and fibreglass rebar also carries environmental implications. The production of steel rebar is energy-intensive and generates a significant carbon footprint. Although steel is recyclable, the environmental cost of its initial production can be quite high.

Fibreglass rebar, while not as widely recyclable as steel, is considered more sustainable in certain respects. Its production emits fewer greenhouse gases, and because fibreglass rebar has a longer lifespan without the need for replacement due to corrosion, it can reduce the environmental impact of construction over time. In particular, for projects that prioritize sustainability, fibreglass rebar may be the more eco-friendly choice.

Conclusion

In the debate of fibreglass rebar vs steel, the right choice depends on the specific needs of your construction project. Steel rebar remains a strong contender for projects that require high tensile strength, flexibility, and affordability. However, fibreglass rebar offers significant advantages in terms of corrosion resistance, long-term durability, and environmental impact, making it a superior option in environments where rust and chemical exposure are concerns.

When considering factors like strength, durability, and cost, it’s important to weigh the pros and cons of both materials to ensure that your project is built to last. Whether you're constructing a marine structure, a high-rise building, or an industrial facility, understanding the benefits of each material will help you make an informed decision.

Call to Action:

Before starting your next construction project, consult with experts and consider the specific demands of your environment and project design. Choosing the right rebar material could save you time, money, and maintenance in the long run.